FIBER OPTICS network WITHOUT DIGGING? The solution is SYSTEM PACK

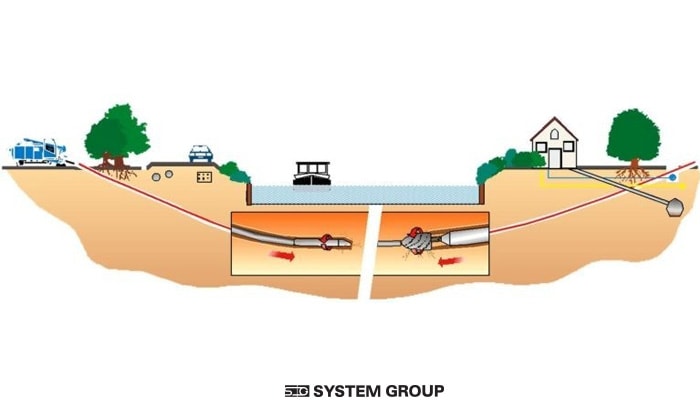

Many companies and many Italian and international telecom operators are increasingly experimenting and promoting the No-Dig laying technologies. The main purpose is to avoid the preparatory excavation for the laying of the optical fiber infrastructure, as it is very expensive and has an impact on the territory, with the advantages of minimizing the followings:

– the handling of heavy vehicles;

– the use of public ground, in relation to both time and surface;

– the laying times of the optical fiber infrastructure;

– the deterioration of the road surface;

– the socio-economic inconveniences caused to the traffic, to pedestrian and to commercial and productive businesses (mobility alteration and a big amount of particles in the air).

These techniques also make it possible to avoid having to transport the excavated material to the landfill site, and then having to stock up with new suitable arid material for the pipe embankment process. This allows a drastic reduction of the environmental impact (CAM criterion – minimum environmental criteria imposed by the Italian Ministry of Environment), as well as per the economic impact.

In addition, these techniques contribute to have an increased safety on site due to the absence of open-cut trenches.

System Pack is the System Group’s solution for the NO-DIG tech in the telecommunications sector.

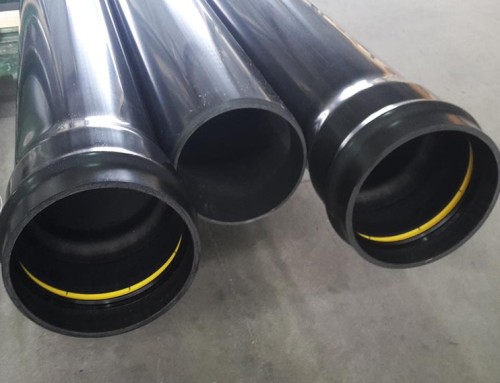

The System Pack, is composed by an HDPE (high density Polyethylene) conduit that contains 7 microducts.

This configuration allows the system to be flexible and at the same time resistant to traction forces, therefore suitable both for common trenching and trenchless techniques.

The microducts are all made of HDPE, with a smooth outer surface while the internal surface is equipped with axial reliefs to reduce the friction surface with the cable during threading and thus obtaining a reduction of friction from rubbing.

To facilitate their correct identification within the System Pack, each microduct can be supplier with co-extruded colored bands on the outer surface or can be made completely in one color, with or without coextruded bands.

The different colors on each microduct will allow it to be distinguished and recognized from the others.

The version of the SYSTEM PACK with SILICONE provides a silicone coating inside each microduct, to further reduce friction during the threading of the cables.

The following video illustrates a typical use of the System Pack by System Group:

To have more information, click here : =====> PRODUCT

This post is also available in: Italian