INFINITANK GREASE AND GRIT SEPARATORS

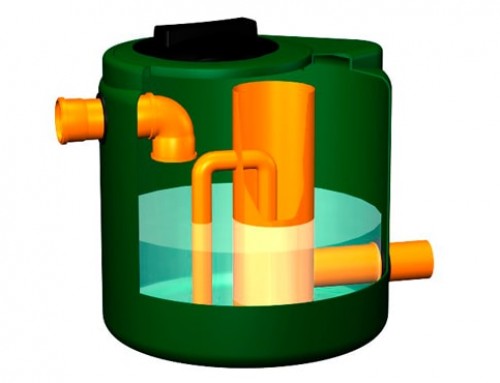

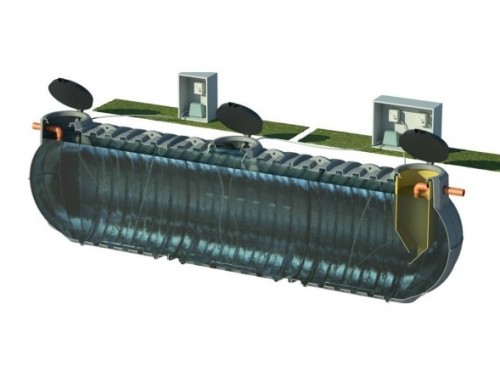

Material:

Modular tank for underground installation in linear high-density polyethylene (LLDPE). Fitted with inlet and outlet pipe in PVC. Sized in accordance with UNI-EN 1825-1 and UNI-EN 1825-2 norms to guarantee a sewage retention time of at least 4 minutes at peak flow and more than 15 minutes at mean daily flow rate.

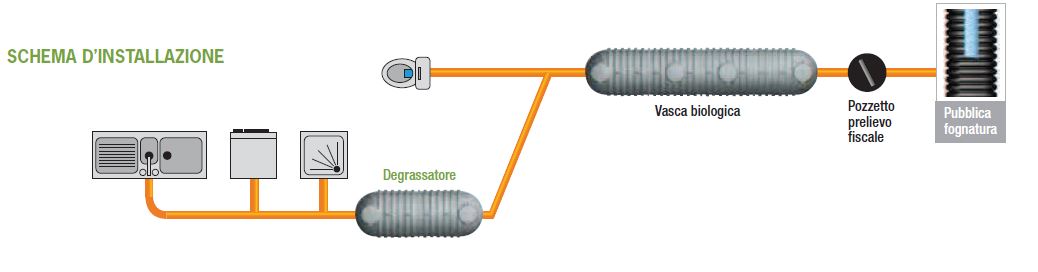

Application:

The grease separator is a physical pre-treatment process that removes oils, foams, greases and all substances with specific weight inferior to that of the effluent.

Use and maintenance:

The substances removed by floatation accumulate at the surface of the grease separator in the form of a surface crust, while the heavier solids settle at the bottom of the tank to form a deposit of putrescible sludge. It is advisable to provide for the periodic removal of the accumulated materials, an excessive accumulation of sludge in the grease separator can cause septic conditions to develop with the resulting malodorous emissions, in particular during the summer. In this respect, it is advisable to contact the appropriately qualified personnel who will remove the accumulated surface mass and settled sludge as well as any film adhering to the surfaces of the tank, paying particular attention to the sediments that could obstruct the effluent inlet and outlet. The frequency of these operations depends on the amount of greases, oils and sedimentable solids present in the effluent. However, it is highly recommended that the separation chamber is inspected every one or two months.

Installation: Carefully follow the “INFINITANK INSTALLATION INSTRUCTIONS” supplied by ROTOTEC.

This post is also available in: Italian French