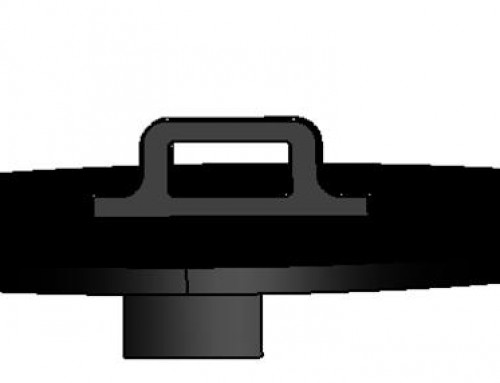

HD PE INSPECTION MANHOLES MADE WITH SPIRAL WALL PIPES BODY

BRIEF DESCRIPTION

HDPE inspection manhole entirely black, consisting of a circular body obtained from a pipe built through the spiral wounding of a polyethylene profile technology. It can be smooth solid or structured, with smooth or profiled outer surface, with customised thicknesses that can be tapered on the outside. The base closing is made with a single or double plate of HDPE welded to the vertical body of the inspection manhole. The upper closing cap is provided with flat plates (with or without metallic structural reinforcements, depending on the sizes) and with manhole reductions, with or without the inner inspection stairs. The diameters range is between DN/ID 800 and 2500 mm, in order to allow the inspection of underground pipes or the placement of adjustment or raising components. There is the possibility to create in-line manholes, vertex manholes, intersection manholes and backdrop manholes. Modules are preassembled at the factory before the shipment through an extrusion welding made by qualified personnel, in order to make faster and easier the installation. Suitable for the connection of all plastic pipe types, both with solid or structured profiles, but also for other pipes. Suitable for applications in areas subject to heavy traffic, combined with an uptight plate for force distribution and in case of groundwater. Wide range of customisable shapes.

MAIN FEATURES

Monolithic quality (high reliability in case of groundwater)

Structural reliability

Lightweight

Easy and quick to install

Plastic behaviour in unstable situations

Wide range of solutions (sizing optimization)

Versatility

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

This post is also available in: Italian French