PE100 – RC type 2 pipe for water “Europas Safe10”

BRIEF DESCRIPTION

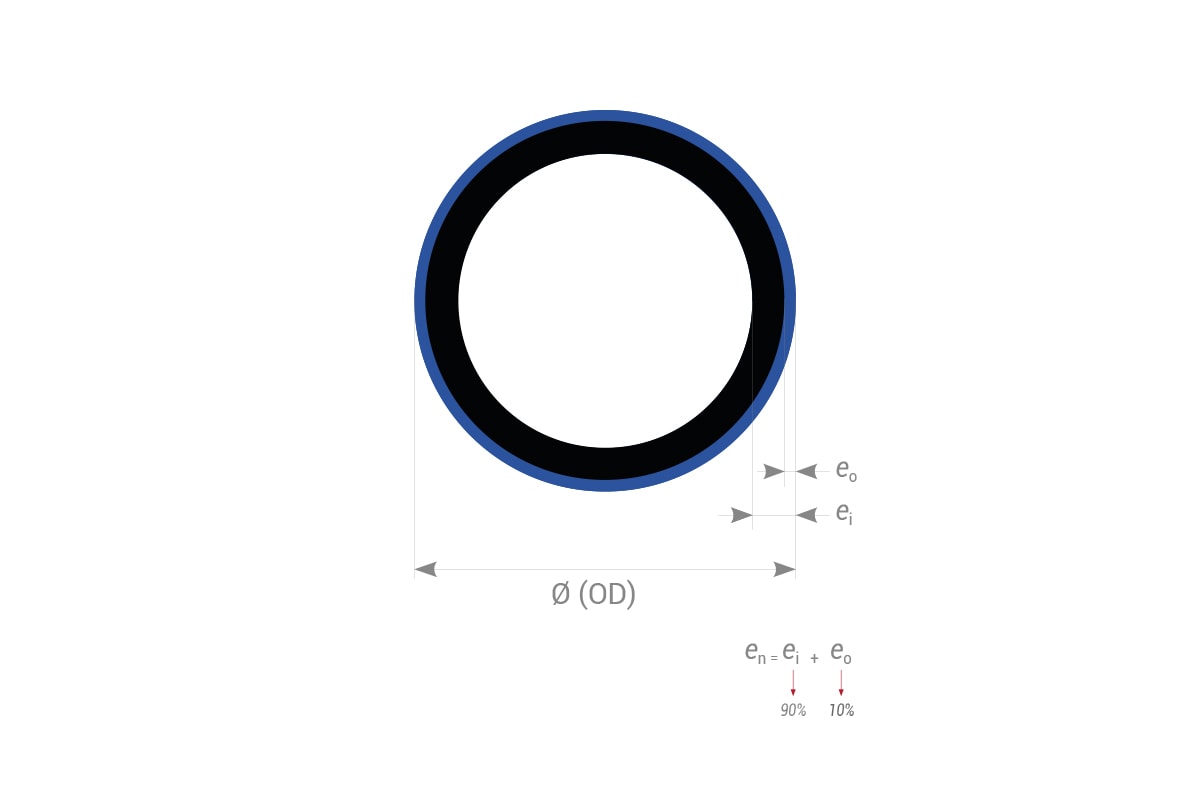

Solid wall pipes made of PE 100 RC (MRS 10 MPa – σS 6,3 MPa) with a smooth inner and outer surface and with high resistance to Slow Crack Growth (SCG).

Type 2 (2 layers) is available with inner black colour wall (90% of the thickness) + outer blue colour wall (10% of the thickness).

Diameters (OD) go from 20 up to 450 mm. Pipes can be provided in coils or bars.

MAIN FEATURES

High resistance to SCG from point loads and surface incisions

Particularly recommended for NO DIG installation techniques

Good bending properties

100% permanent water tightness

Helpful for the detection of external incisions greater than 10%

Plastic behavior in unstable circumstances

Wide range of diameters and pressure classes (sizing optimization)

Wide range of fittings and special pieces , standard and customized

Related to aqueducts, this pipe is in conformity with the EN 1622 standard “determination of threshold of smell and taste”

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorbing capacity

Recyclable

This post is also available in: Italian French