LATEST GENERATION PIPES FOR LARGE DIAMETER SEWER COLLECTOR in MELITO and GIULIANO (CAMPANIA – ITALY)

Together with the technical director of the construction site (Eng. Iuorio) we will discuss why the SGK solution (HDPE big diameters pipes) has been considered the best one from a technical-economic point of view, given the particular laying conditions of the pipe.

The critical issues in the installation of the new collector were the following:

- Minimum laying slope

- Surface laying of the pipelines (low thickness of coating)

- Presence of archeological sites

- Laying on high speed roads (heavy traffic)

In order to solve these problems, the project required a collector with the following characteristics:

- Low roughness

- High resistance to compression

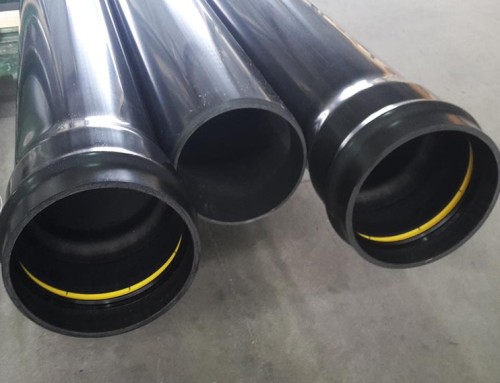

- Large diameter

- Perfect hydraulic seal

For these reasons, the SGK was the solution. Let’s see why:

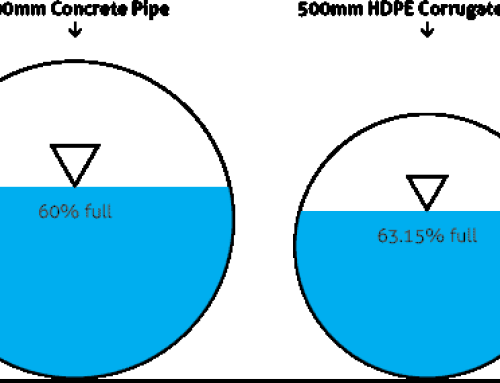

HIGH HYDRAULIC PERFORMANCES

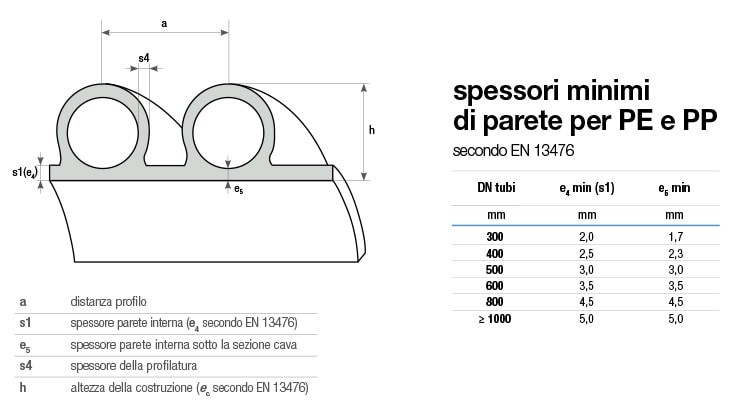

The internal diameters and the hydraulic characteristics of the pipes remain constant over time, regardless the wall thickness or the profile type. This can be found in the very low roughness and the low adhesiveness of the inner wall of the pipes.

The nominal diameter (DN) is the actual internal diameter of the pipe, within the tolerances allowed by the reference standards.

SEALING SYSTEM

The special sealing system, with electro-weldable socket, was one of the decisive elements for the choice. In fact, with the polyfusion caused by welding, there were no points of potential hydraulic leakage or infiltration in the presence of groundwater.

These problems are usually represented by elastomeric gasket joints or other mechanical systems since diameters are large.

SPEED OF INSTALLATION

Thanks to this laying technique, the expected realization times of the 4 parallel pipes of DN 1200 Piping have been considerably reduced.

RECYCLABILITY

In case of interest in studying the subject in detail and discover all the case studies, please contact our TEAM of INTERNAL ENGINEERING dedicated to design support directly, here: SYSTEM GROUP CONSULTING

Or please download our technical SGK catalogue here: SGK technical Catalogue

Keep following us with the next case history.

This post is also available in: Italian