Wastewater treatment plant: reduce installation costs with Depurblock

Rototec S.p.A. is a dynamic company in constant growth, with a high presence throughout the Italian country and also abroad (France, Spain, etc.). It was born in 1999 inside System Group, which is leader in the manufacturing field of complete drainage systems (pipes, fittings, special pieces, etc.).

Since the beginning, Rototec has specialized in the production of linear polyethylene tanks by adopting the rotational molding technology. The rotomolded items are used for the production of civil wastewater treatment plants, for the run-off water treatment and the creation of integrated systems for storage and re-use of rainwater and drinking water.

Depurblock, the innovative solution for wastewater treatment plants

Rototec always pays attention to the market request, to anticipate new trends and to the products’ development and improvement.

For 2020, the company wanted to put into practice a real transformation: it went from the traditional wastewater treatment plant made of single products (one for each type of treatment), to a complete structure in single-piece.

The creation of this range of products was possible thanks to the application of underground modular tanks (Infinitank, Minitank, Nanotank). This is the beginning of Depurblok family, in which single units become actual wastewater treatment stages.

Depurblok family members

- IFABLOK: primary sedimentation + oxidation section

- ANABLOK: primary sedimentation + anaerobic trickling filter

- BIOBLOK: primary sedimentation + ventilated biofilm section (MBBR)

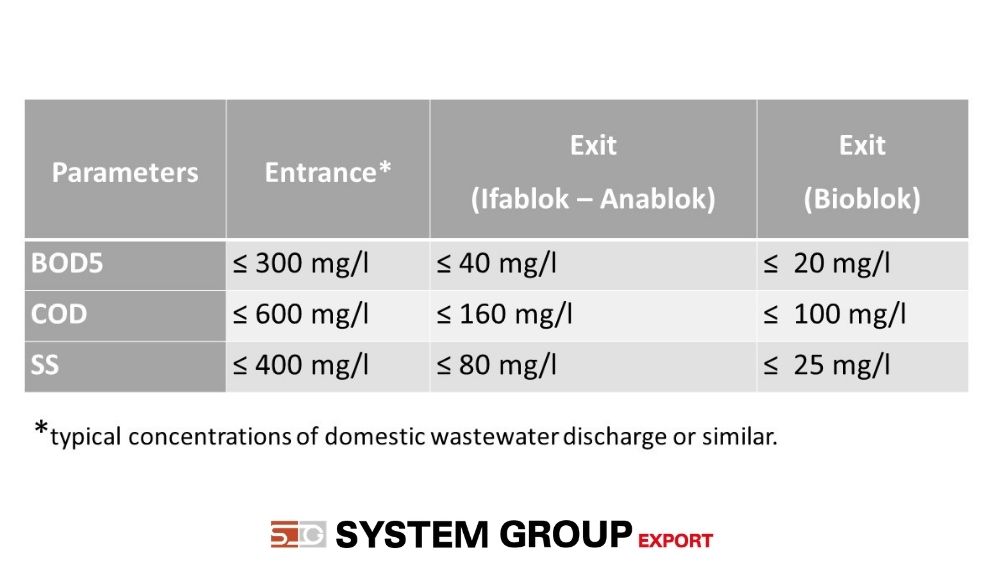

These wastewater treatment plants provide a service to a range of users which are the equivalent of 4 – 140 inhabitants. In addition, they provide a high performance in terms of reduction of polluting materials:

Depurblok benefits

- Faster handling: shift of a single product instead of different tanks;

- Reduction of excavation size: excavation for a single tank;

- Optimization of construction’s cost: faster installation speed and more time and money saving;

- Easier maintenance: all tanks have manholes for inspections.

A wastewater treatment plant with Depurblock in Greece – 2020

A complete wastewater treatment plant serving a hotel of 50 equivalent inhabitants. The plant was required by a Greek partner who was planning a hotel in the island of Mykonos asking strict discharge parameters. To meet his request, we suggested the complete Depurblok MT6000 system, which consists of a septic tank for primary sedimentation of 300 L and a secondary purification tank MBBR of 300 L. Considering the discharge parameters requested by the customer, we thought it was appropriate to add a further primary sedimentation tank to guarantee a greater performance to the plant itself.

What are the benefits of using Depurblok tanks instead of single tanks?

The single-piece plant allows a higher ease and speed of discharge, handling and installation compared to the application of single tanks. The installation of a single-piece tank prevents at the same time the disconnection of the connecting pipes that can be caused by mud flows. As a result, maintenance is easier for the technician and there is a significant reduction in time and costs from the installation to the final management of the plant.

For further information, you can take a look here: “Tanks for water storage and wastewater treatment“.