Drainage channels

|

Need some help?

You find us

on WhatsApp »»

(+393351058009)

|

|

Or just call us on direct line

+39 0722 700 1331

(Mon-Fri 8am-5pm CEST)

|

SABDRAIN CHANNEL

SABdrain channels are in PP (polypropylene), a material having a good mechanical and heat resistance. Polypropylene resists to chemical and atmospheric agents, acids, salts and alkali, oils and petrol. These features make SABdrain the ideal system for roads and highways, parking lots, service areas, cycle and pedestrian paths, industrial sites and airports, as well as more particular installations such as production sites of chemical industries, slaughterhouses and landfills.

PP features make the channel surface extremely smooth while the little roughness of the surface allows the water to flow easily, avoiding the accumulation of deposits and thus facilitating the cleaning. The PP SABdrain channels are available with grid in PP, galvanized steel, stainless steel and cast iron, for all load classes and for any requirement.

BRIDGEDRAIN

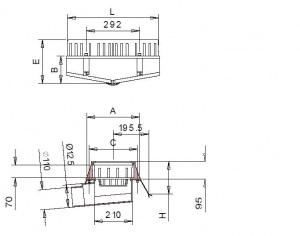

BRIDGEdrain is produced by Futura S.p.A, System group subsidiary and is specifically designed for bridges and viaducts for draining water from road surfaces. BRIDGEdrain consists of three parts:

1) A lower part, rotomoulded in 100% virgin HDPE, made  by the collection chamber with a DE125/DE110 reducer forming the vertical or lateral outlet.

by the collection chamber with a DE125/DE110 reducer forming the vertical or lateral outlet.

2) An upper part consisting of a draining frame and relative cover grid, both in D400 cast iron.

3) N. 4 galvanised steel anchors, fixed to the HDPE body, for embedding in the concrete, complete with fixing screws.

CANYON, Embankment Channel

The CANYON system consists of channel sections manufactured entirely in POLYETHYLENE, suitably reinforced with lateral stiffeners, for use as an alternative to the traditional heavy concrete channels used to channel rainwater on steep slopes such as road and railway embankments.

Since Canyon is made entirely of PE, there are some specific advantages:

LIGHTNESS

The Canyon system channel, manufactured in PE, has an average weight 23 times lower than the equivalent channel in concrete (average weight of a Canyon channel is 1.5 kg, average weight of a concrete channel is 35 kg).

SAFETY

Substantial reduction in incidents on-site during handling (the weight is well below that provided for by Legislative Decree 81/08).

SPEED AND SAVINGS

Easy to transport and lay, greatly reducing site time and costs.

TRANSPORT SAVINGS

Possibility to load bigger quantity of pieces.

Download the catalogue!

Download the catalogue!

Fill in the form here below,

You will receive the link

to download the catalogue.