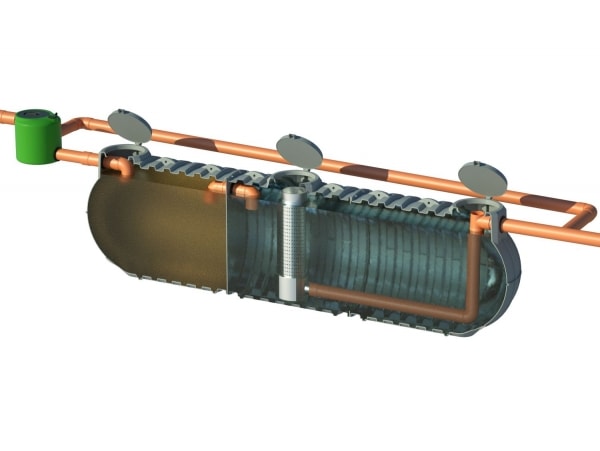

SGK EcoTanks – first flush rainwater harvesting systems made by HDPE big size spiral pipes

BRIEF DESCRIPTION

First flush rainwater harvesting systems composed of HDPE big size spiral pipes.

The system consist of:

- A floodway manhole which ensure the bypass operation in case of clogging of the final disposal tank

- A connecting pipeline between the manhole and the tank

- A float for closing the water inlet

- A tank for temporary storage, provided with:

- 2 (or more) inspection chambers

- Inner baffles

- Timed lifting pump (electric control panel included)

- Low-profile or raised base for pumps housing

- Water outlet pipeline

Upon request, the system can also be provided with a baffle for the collection of grit settled on the tank floor.

PLEASE NOTE: This system is usually adopted in order to store and lift the water which has to be sent to the following tanks for grit removal and oil separation, but it can be used for retention systems with different sizes as well, thanks to the system modularity.

MAIN FEATURES & BENEFITS

Circular tanks

Wide range of diameters

Wide range of structured profiles (moment of inertia) – ring stiffness

Socket connections with the electrofusion technology

High reliability of permanent connections tightness

Customised creations

Modular construction with pre-assembled elements at the factory

Lightweight and quick installation

High chemical and abrasion resistance

Inert to stray currents

High tolerance in seismic zones

Professional design support offered by System Group

On-site assistance available

Recyclable