HDPE solid wall pipes for cable protection HIGH VOLTAGE

ELECTROPIPE – HV

BRIEF DESCRIPTION

High density polyethylene (HDPE) pipes with a solid wall profile, internally and externally smooth, black with red coextruded stripes on the external surface, connectable by butt polyfusion welding (verified according to ISO 13953) in order to be suitable also for the execution of trenchless poses (TOC).

In order to ensure the normal operation of the system with cable temperatures up to 80 ºC, and short-circuit temperatures (not exceeding 5 seconds) up to 160º C, the mechanical characteristics of the pipe meet the requirements of the following standards:

- IEC 62067: Verification of the mechanical characteristics of HDPE conduits for cable insulation for nominal voltages from 150 to 500 kV, before and after thermal aging

- ENA TS 12-24: verification of crushing strain resistance at 50 ºC and 75 ºC

The range of diameters includes:

- all those required by CEI EN 61386, ɸ 25 to 250 mm, in various thicknesses for the different classes of annular rigidity

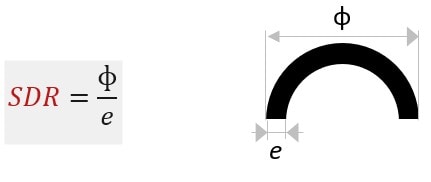

- all sections up to ɸ 1200 mm, with reference to the SDR classes required by EN 12201-2

MAIN FEATURES & BENEFITS

- IMQ certified standard 61386*

- CE marking*

- with PSV brand (Second Life Plastic) on request – Circular Economy

- PE joint system with EPDM sealing seals, with IP66 and IP68 protection rating for ɸ 200 – 225 – 250 mm pipes

- head/head and electrofusion joining system possible

- 100% permanent watertight seal

- internally and externally bevelled ends

- Wide Radius Foldability

- low elastic modulus

- plastic behaviour in unstable situations

- wide range of fittings and special parts, standard and customized

- inertia to stray currents

- high chemical resistance (ISO/TR 10358 – ISO/TR 7474)

- High shock absorption capacity

- total recyclability

* for the diameter range included in standard 61386

SPECIFICATION ITEMS

HDPE pipes for underground cable threading systems according to CEI EN 61386

Supply and installation of high-density polyethylene (HDPE) pipes, with solid wall profile, smooth internally and externally, black with coextruded red stripes on the external surface, for the construction of underground cable threading systems. The pipes must be equipped with a mark of conformity of the product to the standard CEI EN 61386-1-24 issued by an accredited third-party certification body, with crush resistance class ≥ … N and impact resistance classification “N series”.

Piping must be tested according to ISO 13953 by accredited third party to verify conformity to butt welds. The mechanical characteristics of HDPE cable insulation pipes with nominal voltages from 150 to 500 kV shall be verified according to IEC 62067, before and after thermal ageing. The verification of crushing deformation resistance at 50 ºC and 75 ºC shall be verified according to ENA TS 12-24. The marking of the pipes must bear in full all the elements required by the reference standard, in addition to the product quality mark and the CE marking. The pipe manufacturer must be regularly registered with the PolieCo Consortium (D.Lgs. 152/2006 – art. 234).

HDPE pipes – class 450* N

ɸ 50 mm (sp. 3,0 mm)

… ….. …

ɸ 200 mm (sp. 9,6 mm)

ɸ 225 mm (sp. 10,8 mm)

ɸ 250 mm (sp. 11,9 mm)

* Standard ring stiffness classes: 450 N – 750 N – >750 N

HDPE pipes for underground cable threading systems

for custom sizes not included in CEI EN 61386

Supply and installation of high-density polyethylene (HDPE) pipes, with solid wall profile, smooth internally and externally, black with coextruded red stripes on the external surface, for the construction of underground cable threading systems. The HDPE material of the pipes must meet the requirements of CEI EN 61386-1, and the normalized dimensional ratio must be SDR … according to UNI EN 12201-2. Piping must be tested according to ISO 13953 by accredited third party to verify conformity to butt welds. The mechanical characteristics of HDPE cable insulation pipes with nominal voltages from 150 to 500 kV shall be verified according to IEC 62067, before and after thermal ageing. The verification of crushing deformation resistance at 50 ºC and 75 ºC shall be verified according to ENA TS 12-24. The marking of the pipes must bear in full all the identifying elements of the product and the manufacturer, and repeat at intervals not exceeding 1 m. The manufacturer of pipes must be regularly registered with the mandatory PolieCo Consortium (D.Lgs. 152/2006 – art. 234).

HDPE pipes – SDR17*

… ….. …

ɸ 200 mm (sp. 11,9 mm)

ɸ 225 mm (sp. 13,4 mm)

ɸ 250 mm (sp. 14,8 mm)

… ….. …

ɸ 1200 mm (sp. 71,1 mm)

Standards: SDR26 (SN4) – SDR21 (SN8) – SDR17 (SN16) – SDR11 (SN64)

Upon request, this type of pipe can also be equipped with Pipe Tracer system, so as to become:

- traceable with high plano-altimetric accuracy

- referential (containing information on the type of service and its management)