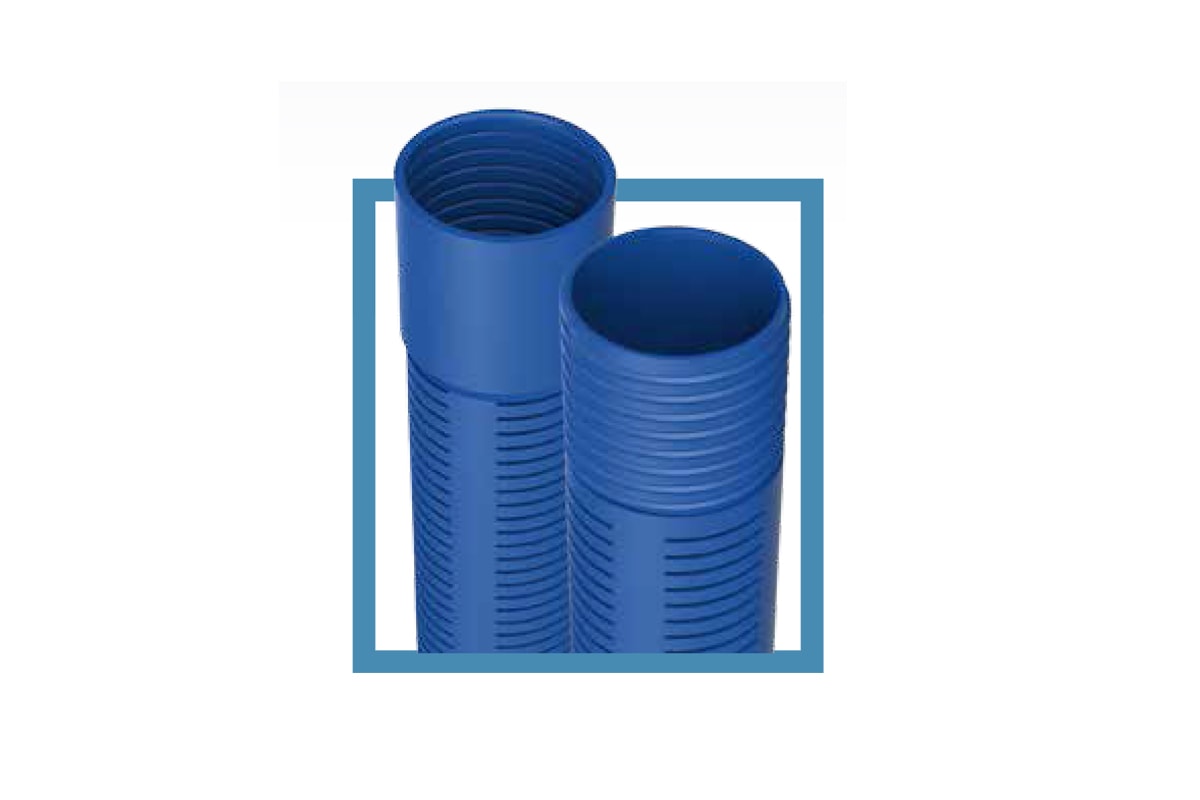

BLACKCOR – HDPE double wall corrugated pipe for cable protection

BRIEF DESCRIPTION

Double wall corrugated pipes made of high-density polyethylene (HDPE), smooth on the inside wall and corrugated outside, for underground cable protection networks.

Diameters (DN/OD) go from 40 up to 200 mm, all available in coils, and in lengths from DN75 mm size.

Standard colour is totally black, to increase the UV resistance. It can be equipped with one coextruded coloured stripe on the outside wall, according to customers’ need.

MAIN FEATURES

Wide range of diameters

Ring stiffness: 450 – 750 N

Impact test classification: N

Close bending radius

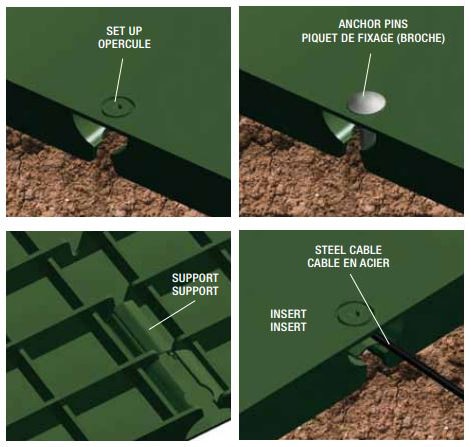

Coupling connections

Accessories: Coupling sleeve + polypropylene/polyester wire puller.

High UV resistance

Lightweight and easy to install

Standard bands color: white/light grey, customized color available on demand.

High chemical resistance

Inert to stray currents

Recyclable

TECHNICAL CHARACTERISTICS

UV resistance according to EN1297 test, up to 5000h (one year warranty)

Crush resistance: 450N – Standard EN 61386-1/2008 and EN 61386-24/2010 series N (IIP and IMQ certified)

Bending radius: 15 times the outer diameter.

Operating limits: -50 °C / +60 °C.

Electrical rigidity*: Excellent (polyethylene 20-30 kV/mm)

*Electrical rigidity, also known as dielectric strength or breakdown voltage, represents the ability of a material to withstand a certain electric voltage before a discharge or breakdown occurs. High electrical rigidity is desirable in materials intended for electrical insulation, such as those used in cables, transformers, capacitors, and other electrical and electronic components.

Electrical rigidity is primarily classified based on the breakdown voltage, which depends on the material and its thickness.