FIRST RAIN WATER TREATMENT SYSTEMS

RULES AND REGULATIONS

In many countries, environmental awareness and related laws require the adoption of first flush water treatment systems in specific situations. These systems separate light liquids (e.g., oils and hydrocarbons in general) from rainwater runoff from impermeable surfaces before it is released into the environment.

Their regulation is governed by relevant regional laws or regulations.

The European technical standard of reference relating to the principles of design, performance and product testing, marking and quality control for the construction of such systems is UNI EN 858-1:2005 “Separation systems for light liquids (e.g. gasoline and oil)”.

UNI EN 858-1:2005 is a harmonized European Union standard, therefore it allows the marking of products as regulated by Regulation (EU) 2024/3110 of the European Parliament and of the Council.

The UNI EN 858-1:2005 standard provides for two classes of separators:

- Class I separators: maximum residual oil content 5 mg/l (coalescing separators)

- Class II separators: maximum residual oil content 100 mg/l (gravity separators)

The UNI EN 858-2 standard provides guidance on the criteria for choosing the type and nominal size of separation systems and, for application to fuel stations, car parks, and roads, recommends the choice of Class I separators in the case of delivery of treated water to surface waters, in accordance with the discharge limits indicated by national legislation: Legislative Decree 152/2006.

“CLASS I” TREATMENT SYSTEMS SGK EcoTanks

SGK EcoTanks first flush water treatment systems are certified in Class I by an independent third party for compliance with the UNI EN 858-1 : 2005 standard.

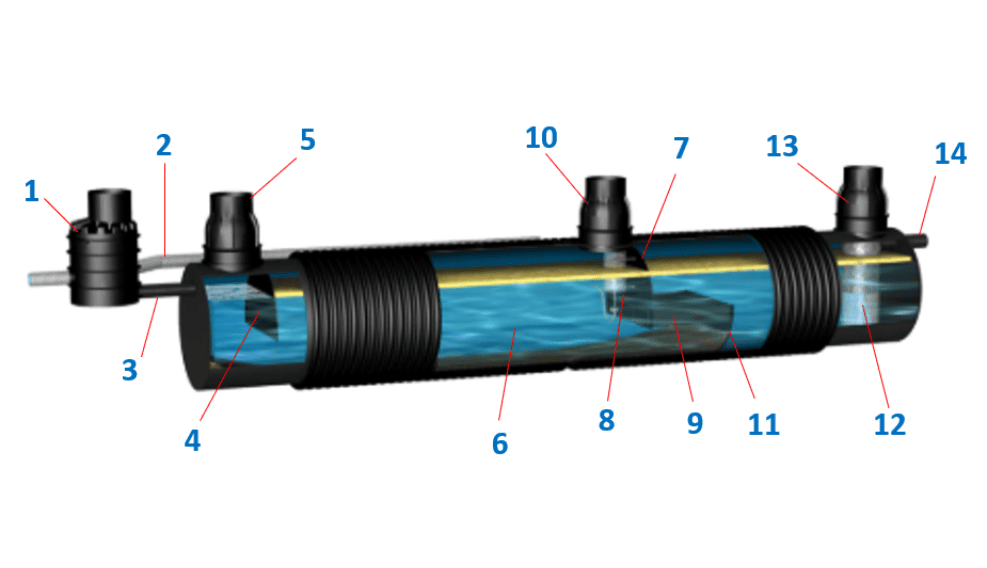

These systems consist of large spiral polyethylene pipes (diameters from DN 800 to 2500 mm), suitably sized in terms of volume and equipped internally to perform the separation of light liquids: by gravity (buoyancy) and thanks to the aggregation effect of oily particles by coalescence. Externally, the system is equipped with the necessary access points for inspection and maintenance throughout its operational life, as well as bypass systems to manage any excess flows.

- bypass well regulates the inflow to the system and access to the bypass

- bypass pipe for transporting water that does not undergo treatment

- inlet pipe sized to regulate the inflow of water into the system

- deflector that calms the turbulence of the incoming water, confines floating solids, and directs the flow downward, promoting the sedimentation of heavy solids (inert)

- inlet well necessary to extract floating solids and sedimented inert materials

- calming tank in which light liquids are separated by flotation

- deflector delimits the calming volume in the upper part of the tank, acts as a support for the possible installation of an automatic valve for the extraction of light liquids and for the fixing of lamellar packs

- float valve (optional) for gravity extraction of light liquids

- PVC lamellar packs (optional) to increase the filtration capacity of light liquids

- inspection well for the extraction of light liquids and bottom sediments, float valve control, and cleaning of lamellar packs

- deflector delimits the settling volume in the lower part of the tank and acts as a fixing wall for the lamellar packs

- Coalescence filter performs an additional separation of light liquids, can be equipped with an automatic gravity shut-off valve

- Well for inspection and maintenance of the coalescence filter

- Outlet pipe for water from the system, positioned slightly lower than the inlet to allow adjustment of the treated flow rate

ADVANTAGES

SGK EcoTanks first flush water treatment systems offer significant advantages:

- wide range of structural options based on installation and operating conditions (presence of groundwater, trafficability for different types of road, port, and airport loads)

- durability, made of high-density polyethylene (HDPE) with high chemical, electrical, biological resistance and resilience in seismic areas

- lightness, allowing for a reduction in the power and size of mechanical handling equipment on site, speeding up installation and consequently reducing installation costs and safety charges

- Modularity, all elements and devices are pre-assembled in the factory, leaving only the connection phases to be carried out on site

- Full support from System Group, both in the design phase (structure and dimensioning of the product), economic evaluation, and optimization and speeding up of installation

- Full regulatory compliance thanks to certification of compliance with the UNI EN 858-1 standard by an independent third party which, compared to self-certification, offers a choice oriented towards transparency, documentary reliability, and protection of the entire supply chain of actors responsible for the quality and administration of the work

- Marking required by law on products covered by a harmonized standard

- Recyclability of the material (HDPE) → circular economy

MARKING (Conformité Européenne)

Marking is a mandatory requirement for all products for which there is a Community standard (directive or regulation) in the European Union, e.g.: UNI EN 858-1: 2005 [Regulation (EU) 2024/3110].

Its presence indicates that a product complies with the essential safety, health, and environmental protection requirements established by European Union regulations for people, animals, and goods, allowing it to circulate freely throughout the European Union, including EFTA (European Free Trade Association) countries: Norway, Switzerland, Iceland, and Liechtenstein.

Regulation (EU) 2024/3110 (Construction Products Regulation – CPR) requires that for each construction product, the supplier must issue the relevant DoP (Declaration of Performance), which contains the intended use of the product (covered by harmonized standards), its performance characteristics, and all elements useful for its traceability.

The affixing of the marking is an act of responsibility on the part of the manufacturer, who guarantees its conformity. Furthermore, selling products without marking, when mandatory, entails penalties and criminal liability, in which traders and/or importers of the products are also involved.

The marking cannot be applied to products manufactured outside the European Union.

MANDATORY MARKING

Therefore, construction products for which harmonized European standards exist may only be marketed if accompanied by both the marking and the relevant DoP.

The designer is the first to establish the expected level of quality and requires the relevant tests from suppliers.

A fundamental aspect is compliance with the law, for which the Designer, the Manufacturer, the Construction Manager, and the Project Manager or Tester of the work who do not require and verify the conformity of construction materials, both in public and private projects, are liable to penalties and civil liability.

Marking requires, in any case, verification of the conformity and performance of the system by the manufacturer who, under certain conditions proving that the verification tests have been carried out, may independently issue (self-declaration) the relevant DoP and affix the marking to the product.

Alternatively, the manufacturer may obtain certification from an independent third-party body, which is usually preferred and required by contracting authorities and designers when certified products are available on the market, as this avoids any liability falling on the supply chain responsible for controls in the event of false declarations.

This post is also available in: Italian