Contracting authority: NAPLES INTERNATIONAL AIRPORT (Italy)

Title of the work: Conveyance of the first rainwater from the aircraft APRON2 to public sewer system

Period: materials delivered in July 2018

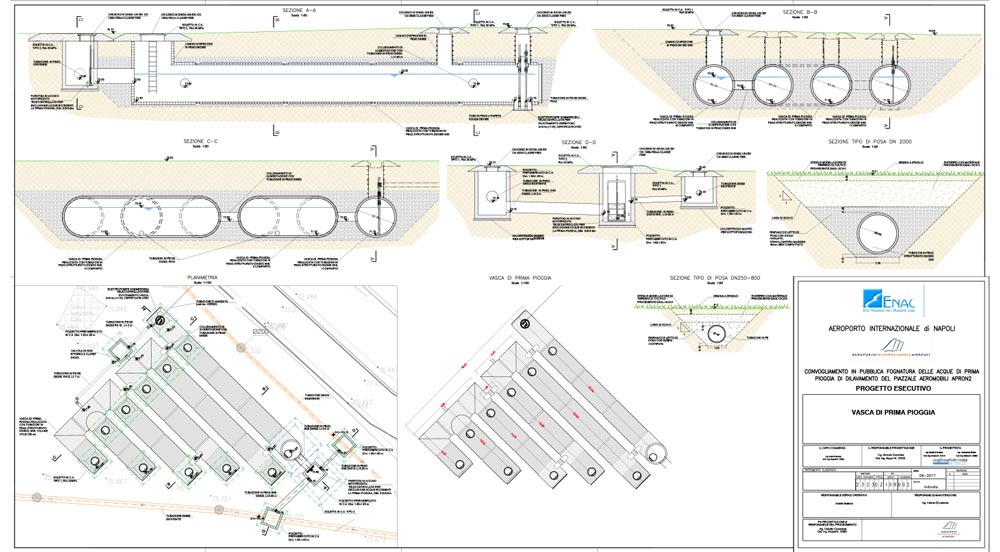

CENTRALTUBI S.p.A. delivered the artefacts built for the construction of the first rain water treatment system in APRON square of the international airport of Capodichino (Naples – Italy). The system was built with PE pipes.

The materials used were:

- PE pipes with structured wall profiles, SGK spiralled type, ID 2000 mm (DIN 16961 SN8 equipped with electrofusion socket system), for the construction of battery accumulation volumes of the first rain water

- Smooth PE pipes, with solid wall profile, OD 500 mm SDR26 (UNI EN 12666 SN8) connected with electrofusion sleeves, for connections between tanks

- Smooth PE pipes, with solid wall profile, OD 250 mm SDR17 (UNI EN 12201-2 PN10), for the realization of the bottom connections for emptying of the system.

System useful volume = 280 m3.

The system also required the realization of the following special pieces, both for access to the inspection and maintenance operations of the system:

- 1 rainwater intake manhole with a the vertical body made with a spiralled pipe DN 2000 mm (SGK); with a pedestrian loads resistance of the lid made of PE sheet; with galvanized steel tube reinforcement; with provision for inspection entrance DN 800 mm; with pre-installed aluminium ladder, and equipped with a rainwater inlet socket for connection with corrugated PE pipe DN 800 mm SN8

- 4 90° bends DN 2000 mm SN8 (from SGK spiral pipes)

- 1 TEE 90° DN 2000 mm SN8 (from SGK spiral pipes)

- 10 predispositions for inspections DN 800 mm

- 20 moulded extensions in PE, DN 800 mm, H 1000 mm each

Pumps of the emptying system are placed in a special well, lower than the bottom of the tanks to allow total empting and avoid stagnation of putrid water.

This lowered well is made up of a smooth PE pipe OD 1000 mm, with a bottom made of welded PE sheets. It is equipped with threaded stainless steel fittings for anchoring the coupling feet of two submersible pumps, including stainless steel delivery pipes, ball check valves, DN80 cast iron gate valves and ATEX IEC/EX approved level device regulators.

The system filled the accumulation volumes in sequence using consequential overflow points. It aimed at reducing the fouling of the tanks due to small meteorological events, thus optimizing the maintenance costs of the storage volumes.

The system is emptied at the same time on all tanks, thanks to the bottom connections and the lifting station integrated with the run-off water inlet tank.

The main success factors were:

- General versatility of the system, homogeneous and modular, by using PE pipes (both in terms of design and construction)

- High quality design support taking place in CENTRALTUBI S.p.A. (with the centralized technical department of SYSTEM GROUP)

- Factory production speed and preparation of modules and special prefabricated parts(all identified by numbers to help the site staff executing an easier and correct installation, together with one of our workman)

- Very brief installation time on site (installed in just five days)

- “Lightness” and reduced safety charges

- High expectations of durability, also considering potential local seismic events

- High degree of customization (→ optimization = reduction of maintenance costs)

- System sealing safety (welding with filling material carried out in the factory by qualified and expert personnel + on-site connections using verified electrofusion socket technology)

Download here the documentation:

Spiral pipes: CATALOGUES – PRODUCT PAGE

For more information: CONTACT US

This post is also available in: Italian