SGK – The breakthrough spiraled pipe tailor made for your building site

[ID 1800 PIPE (400 LINEAR METERS) FOR SURFCE WATER DRAINAGE]

The particular situation caused by groundwater presence and the inability to dig deeper, lead to the usage of spiraled PE SGK system for the following reasons:

-

CONNECTION THROUGH ELECTROFUSION SOCKET

The connection through electrofusion socket is the favourite technique for realising monolithic systems, with permanent and safe tightness, homogeneous, with easy and quick installation, both for non pressurized distribution or liquids storage systems and systems with moderate pressure levels.

In particular, it is important for the pipe choice, as the electrofusion welding guarantees a perfect hydraulic tightness both on the inside and the outside.

-

SPEED OF INSTALLATION

Thanks to SGK pipes’ tightness and flexibility, weldings have been done outside the dig. This operation allowed to optimize time and lay pre-assembled bars inside the trench.

-

BENDABILITY

Pipes had some curvature degree. Thanks to the electrofusion connection and polyethylene elasticity modulus it was possible to create the discharge line without laying curves or special pieces. These situation would have lead to an increase of costs for the realization.

-

STRUCTURE OF THE DESIGNABLE PIPE WALL

The spiral technique allows to design the profile, wall thickness and ring stiffness of pipe depending on the application field.

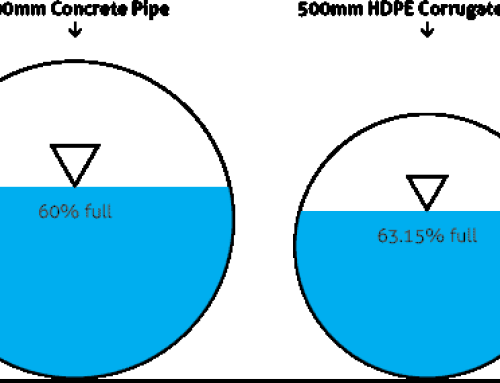

In this case PE pipe’s ring stiffness was at a “minimum” level, equal to SN 2 Kn/m. Thank to this situation, costs are low but the performance of hydraulic system of SGK system were exceptional.

Finally, the SGK versatility allows to use it as a storage tank too, both for water treatment and lamination.

This post is also available in: Italian