Solid wall PE 100 RC (Resistant to Crack) pipes type 2 for pressurized sewerage networks

BRIEF DESCRIPTION

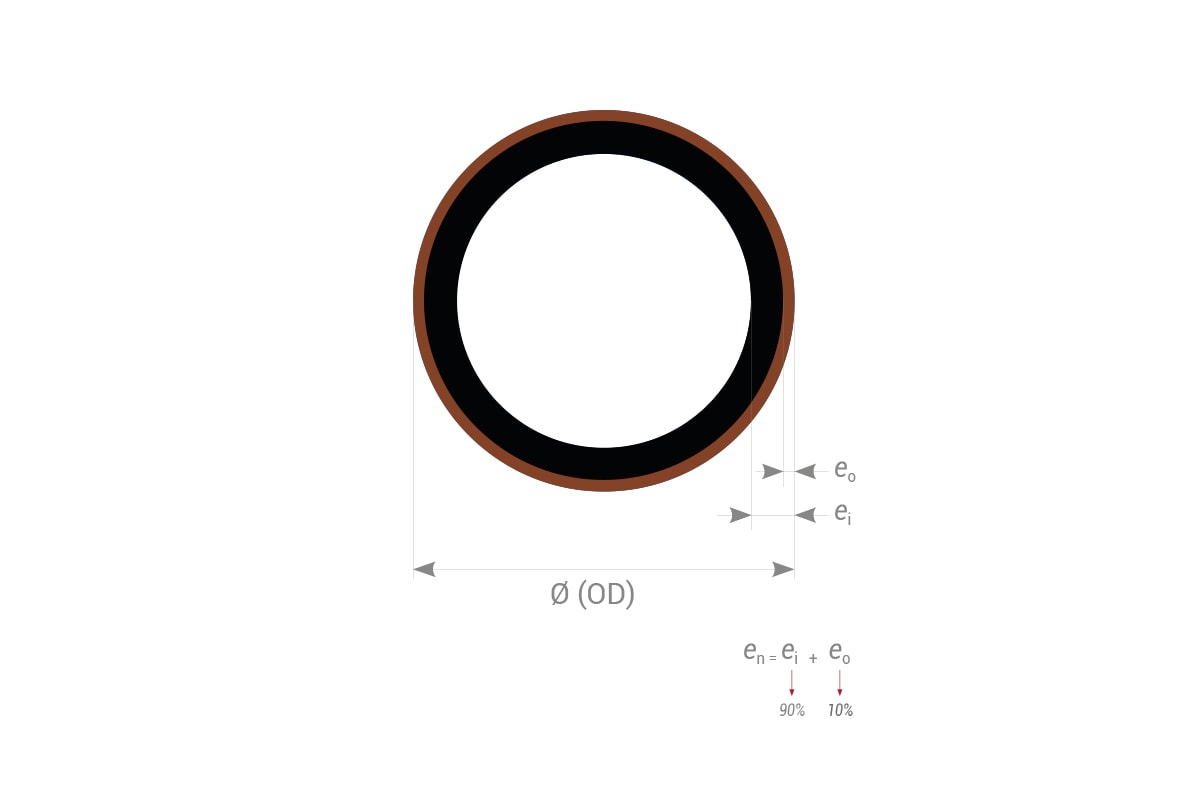

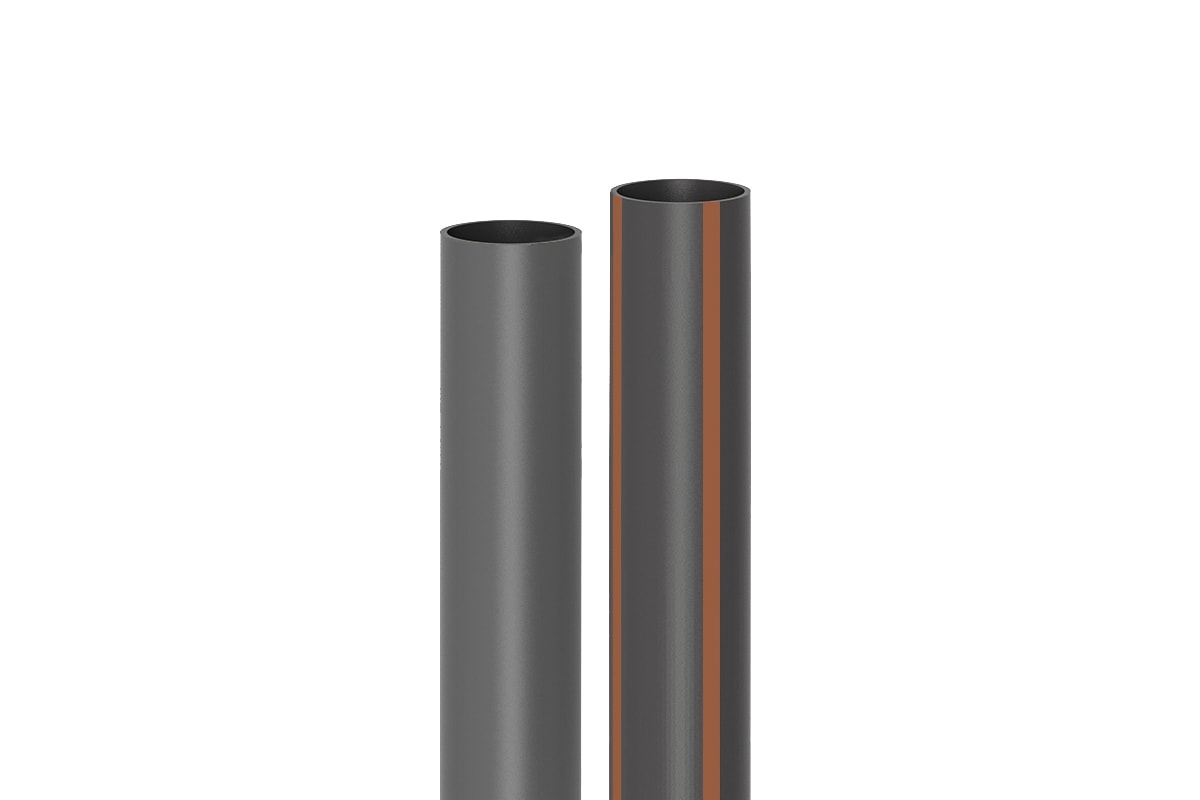

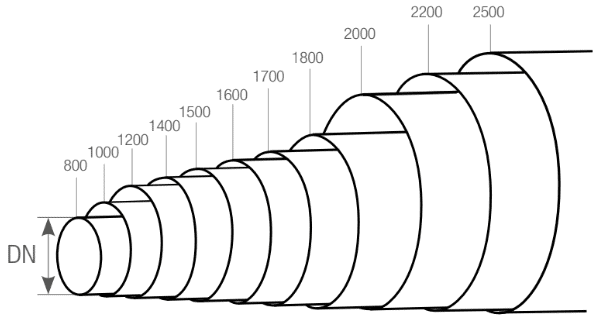

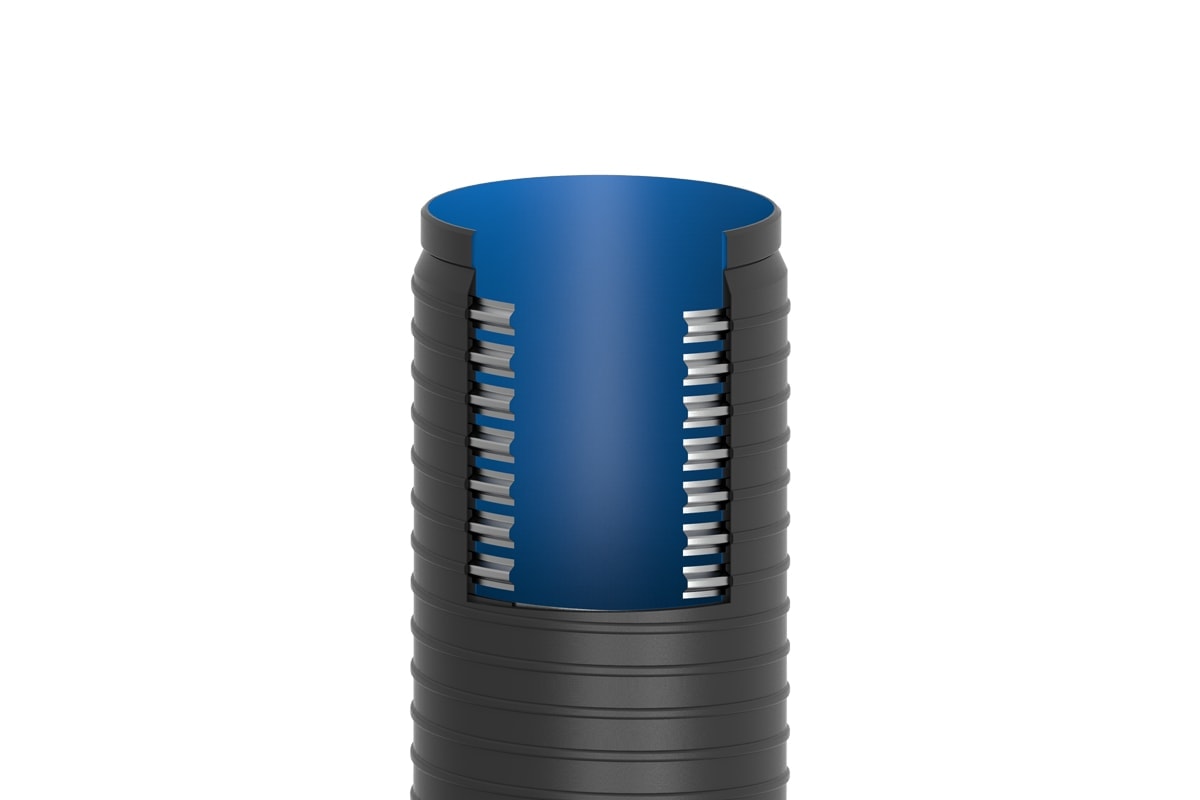

High density polyethylene pipes PE 100 RC (MRS 10 MPa – σS 8,0 MPa) with a smooth inner and outer surface and high resistance to Slow Crack Growth (SCG). Type 2 (2 layers) is available with inner black colour wall (90% of the thickness) + outer brown colour wall (10% of the thickness). The diameters range goes from 75 up to 450 mm and pipes are delivered in bars.

MAIN FEATURES

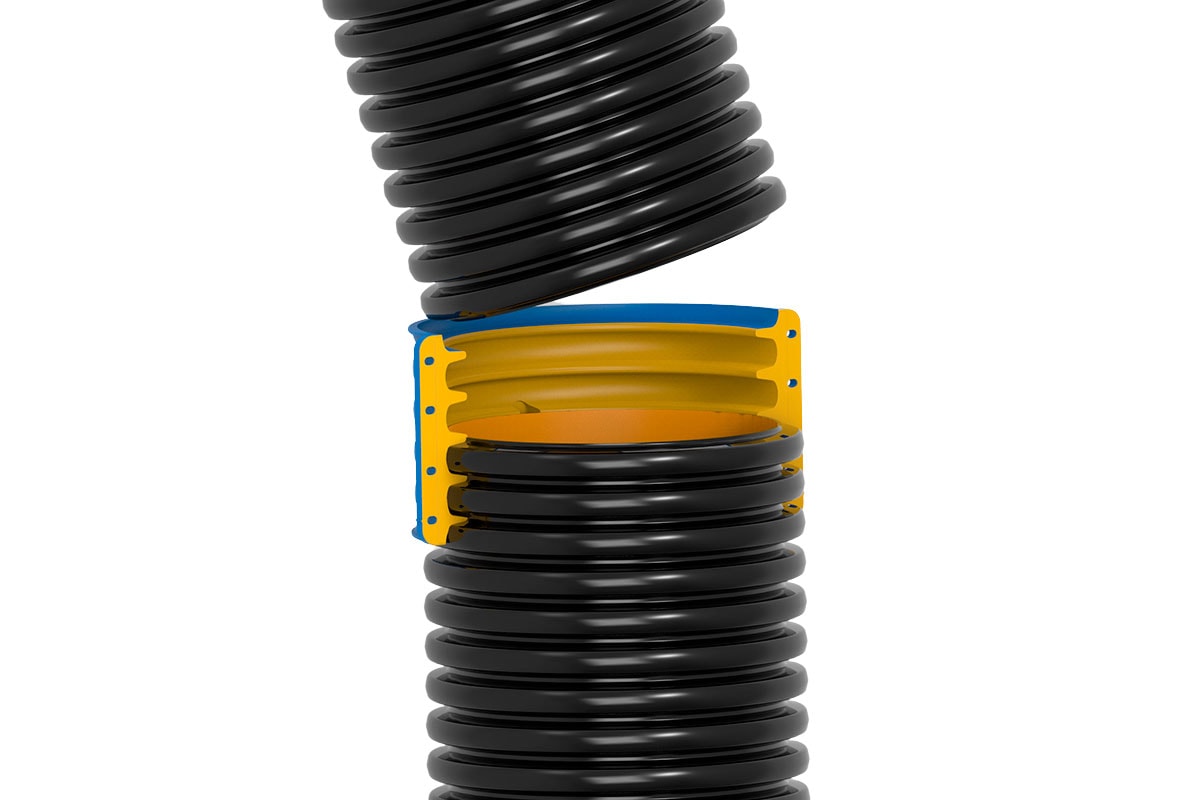

100% permanent water tightness

Good flexibility

Plastic behaviour in unstable situations

Wide range of diameters and pressure classes (sizing optimization)

Wide range of fittings and special pieces, standard and customised

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable