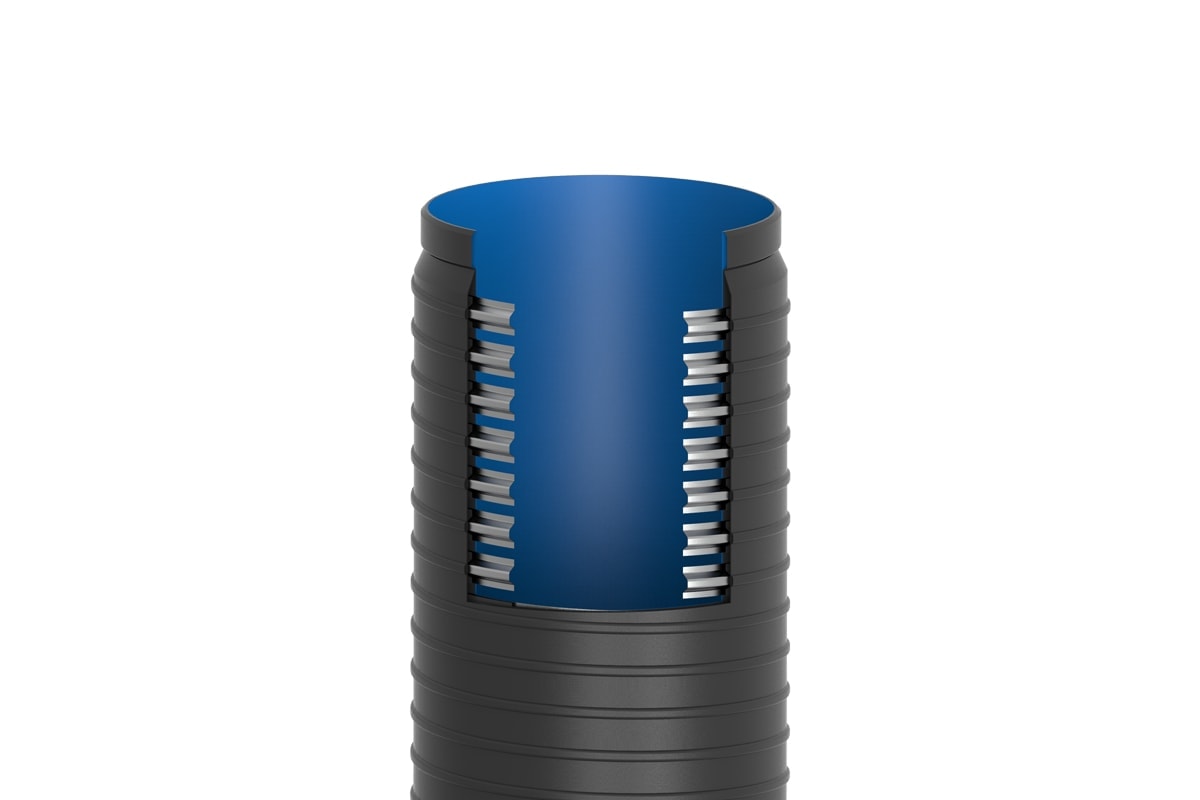

SGS – Composite PE + steel spiraled pipes for non-pressure networks

BRIEF DESCRIPTION

Structured wall pipes made through spiral winding technology that consist of composite profiles of PE and steel. They find application in non-pressure underground sewerage and drainage systems and road embankment crossing. The profiles consists of a smooth inner wall for water flowing, a middle steel section, all coated by a smooth outer surface of PE. All pipe lengths are provided with an integrated junction socket and the respective smooth spigot for the electrofusion or with grooves for the sealing gasket junction system. The diameters range (DN/ID) goes from 800 up to 2000 mm.

Ring stiffness:

| CLASS | A | B | C |

| Rigidity | PS

kPa |

||

| Pipe deflection = 3% | 415 | 620 | 830 |

| Pipe deflection = 5% | 325 | 485 | 645 |

| Pipe deflection = 8% | 215 | 325 | 430 |

The assembly method used to put together the inner and outer PE walls and the middle steel profile is mechanical (not chemical from adhesive substances).

MAIN FEATURES

Wide range of diameters

Flat outer surface

PE and steel profiles are putted together using a mechanical assembly method (no use of chemical tackifiers)

Socket connections with electrofusion technology or with sealing gasket

High reliability of connections tightness

Lightweight and easy to install

High chemical and abrasion resistance

Inert to stray currents

This post is also available in: Italian French