MAGNUM PERFORMANTE SN10 CORRUGATED SEWER PIPE

BRIEF DESCRIPTION

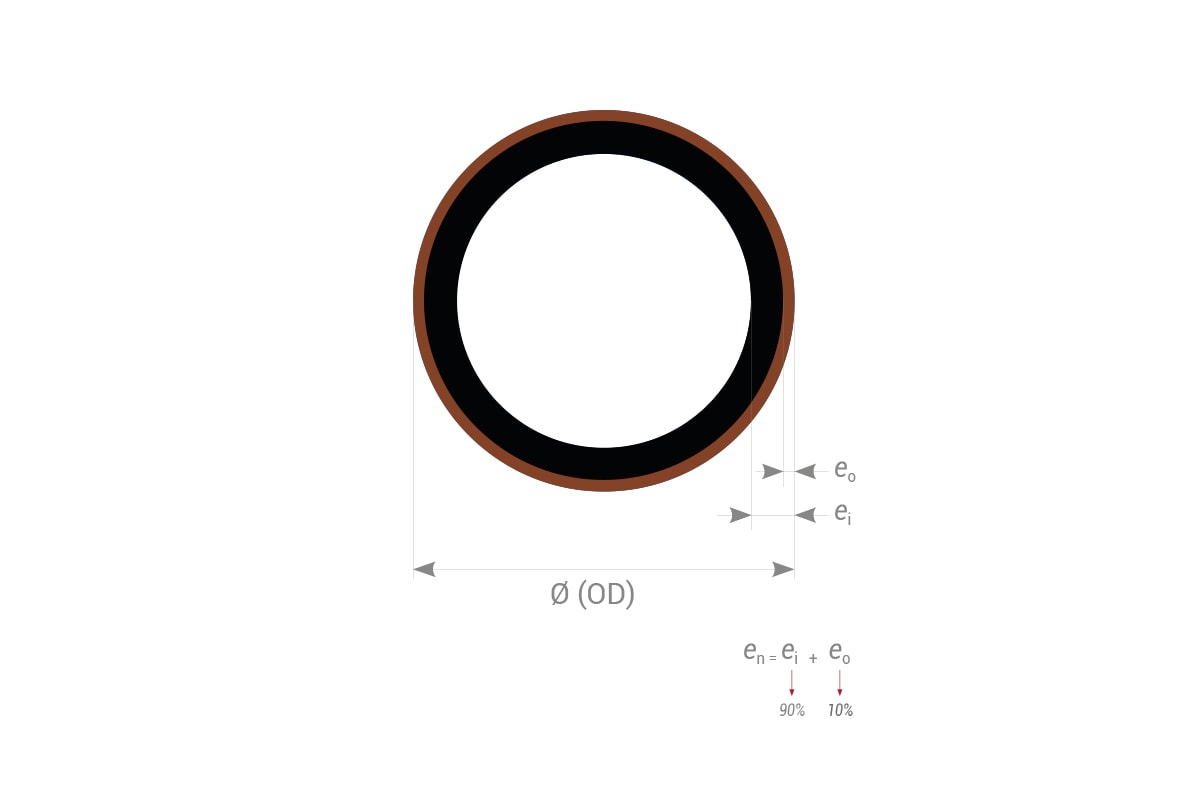

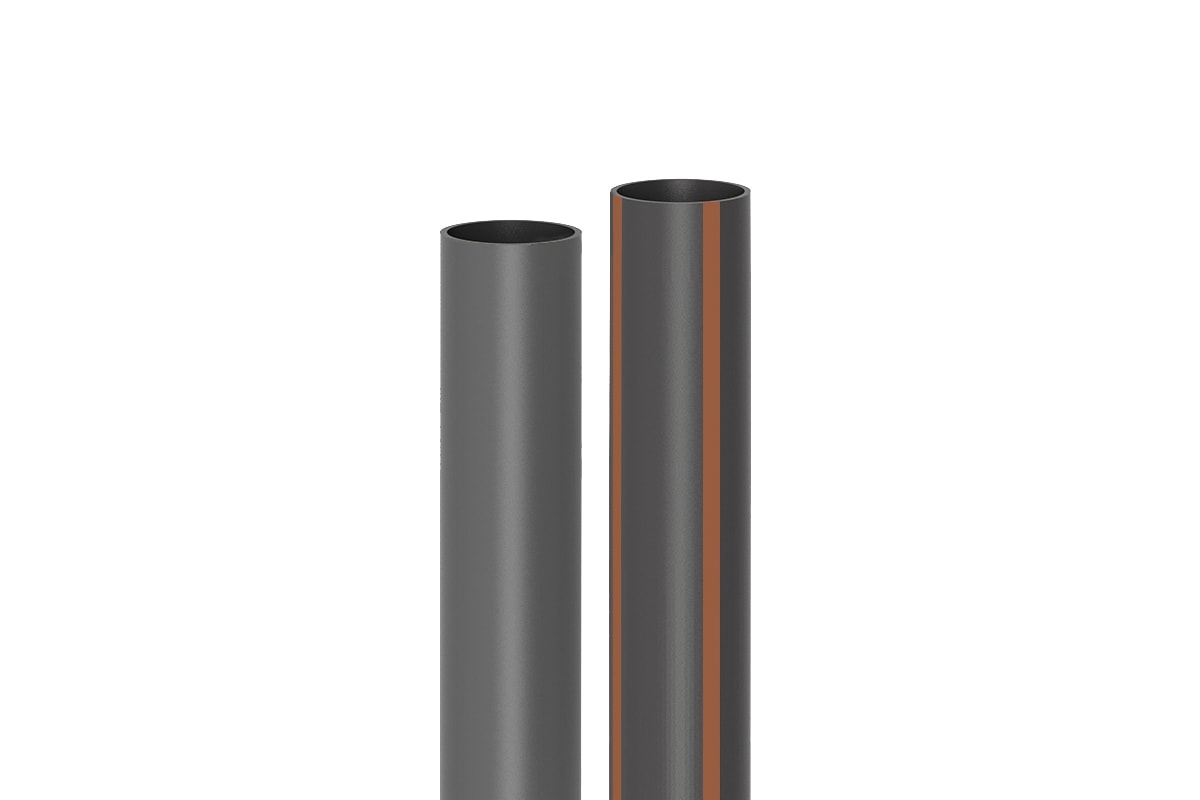

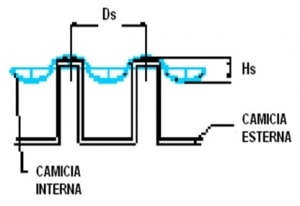

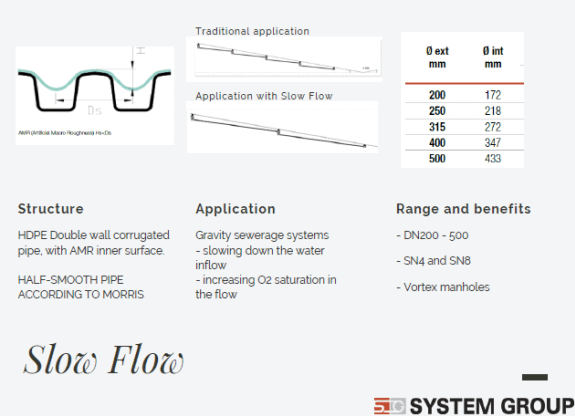

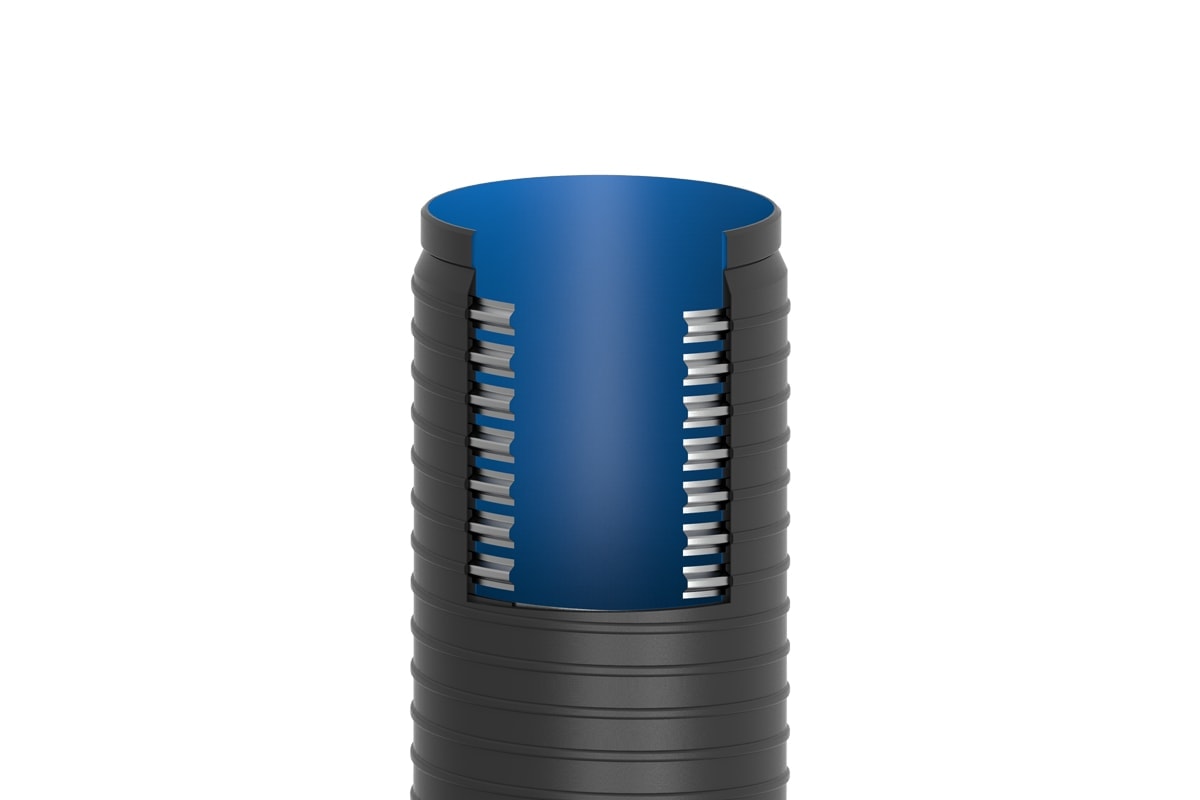

Double wall corrugated pipes made of high density polyethylene (HDPE) with a smooth inner surface and a corrugated outer one, available in black colour.

Pipes are in compliance with EN 13476-3, but with an increased thickness of the inner smooth wall to get long-lasting durability against the abrasion.

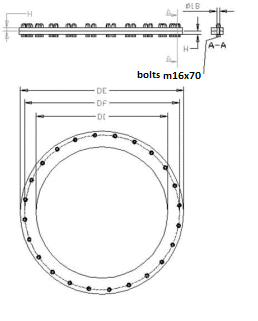

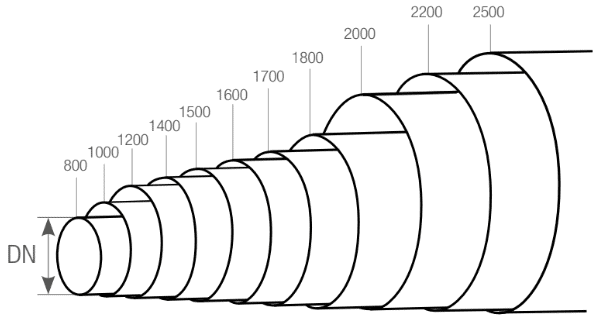

The Outer Diameter (OD) goes from 315 up to 400 mm, pipes are delivered in bars.

MAIN FEATURES

Longer long-lasting durability compared to standard corrugated pipes

Ring stiffness: SN 10 certified

Very smooth on the inside, corrugated on the outside

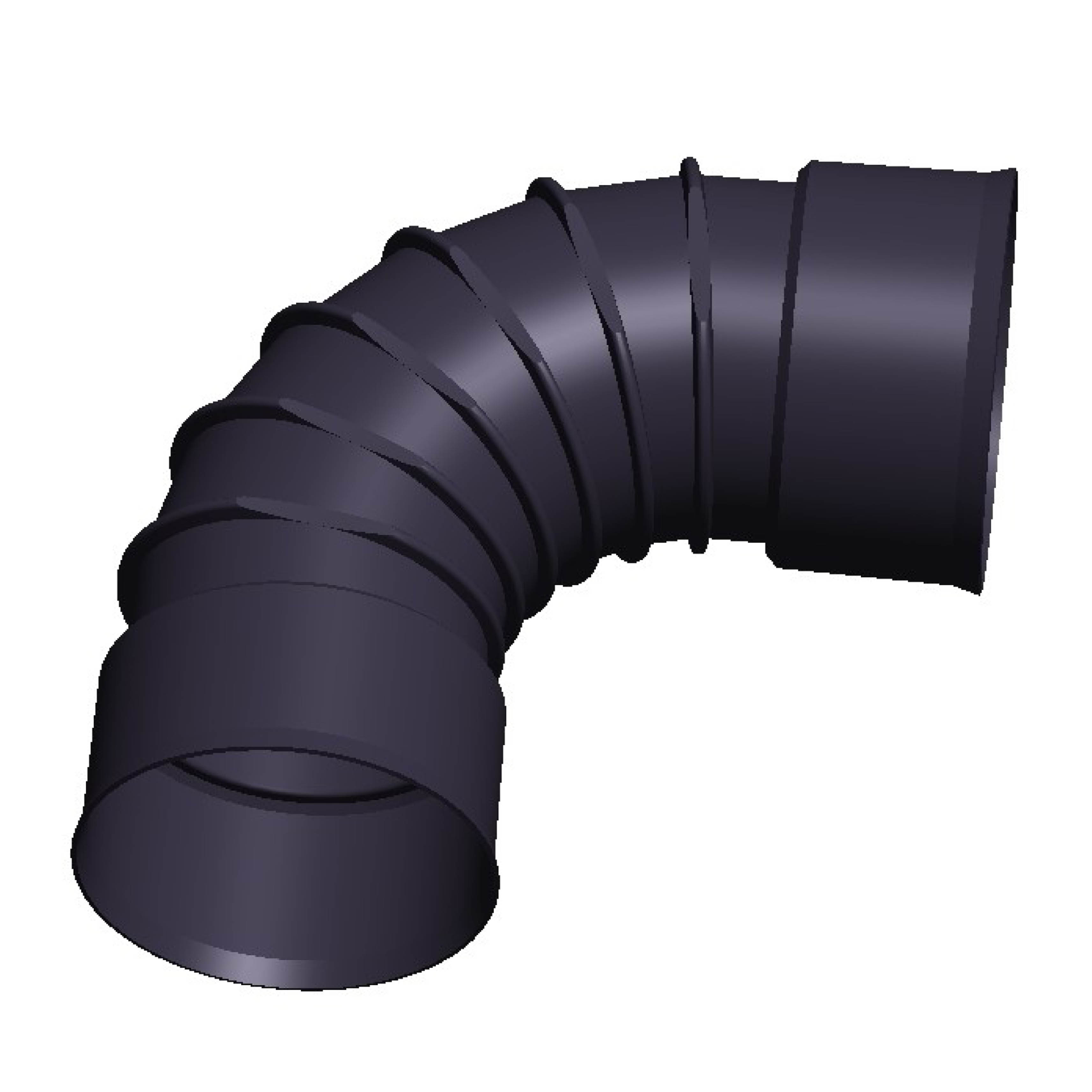

Socket/coupling connections with single/double sealing gasket

Lightweight and easy installation

High chemical and abrasion resistance

Inert to stray currents

Recyclable