PE STEEL transition fittings

BRIEF DESCRIPTION

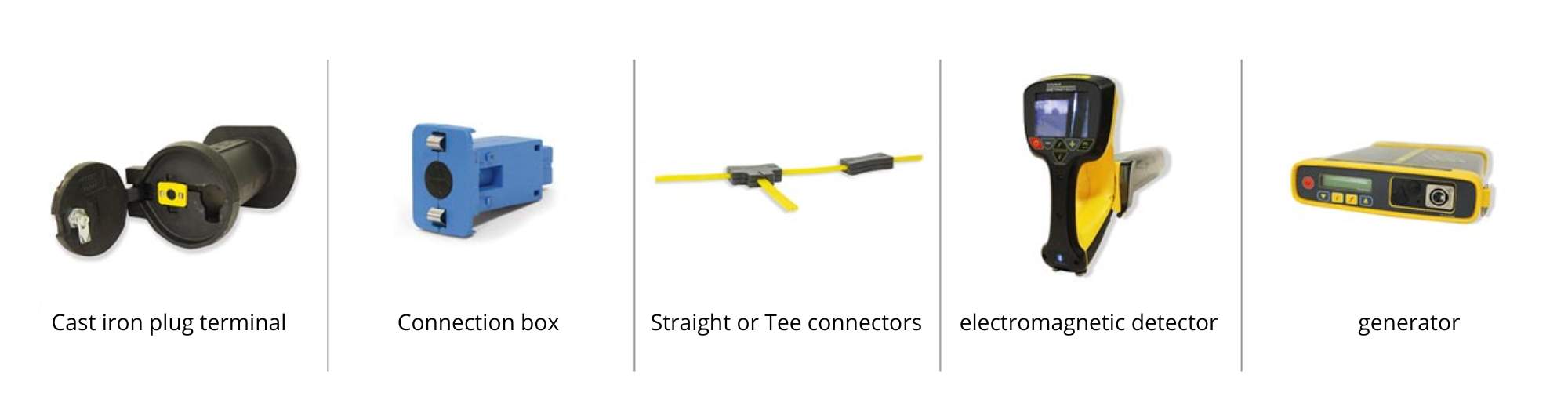

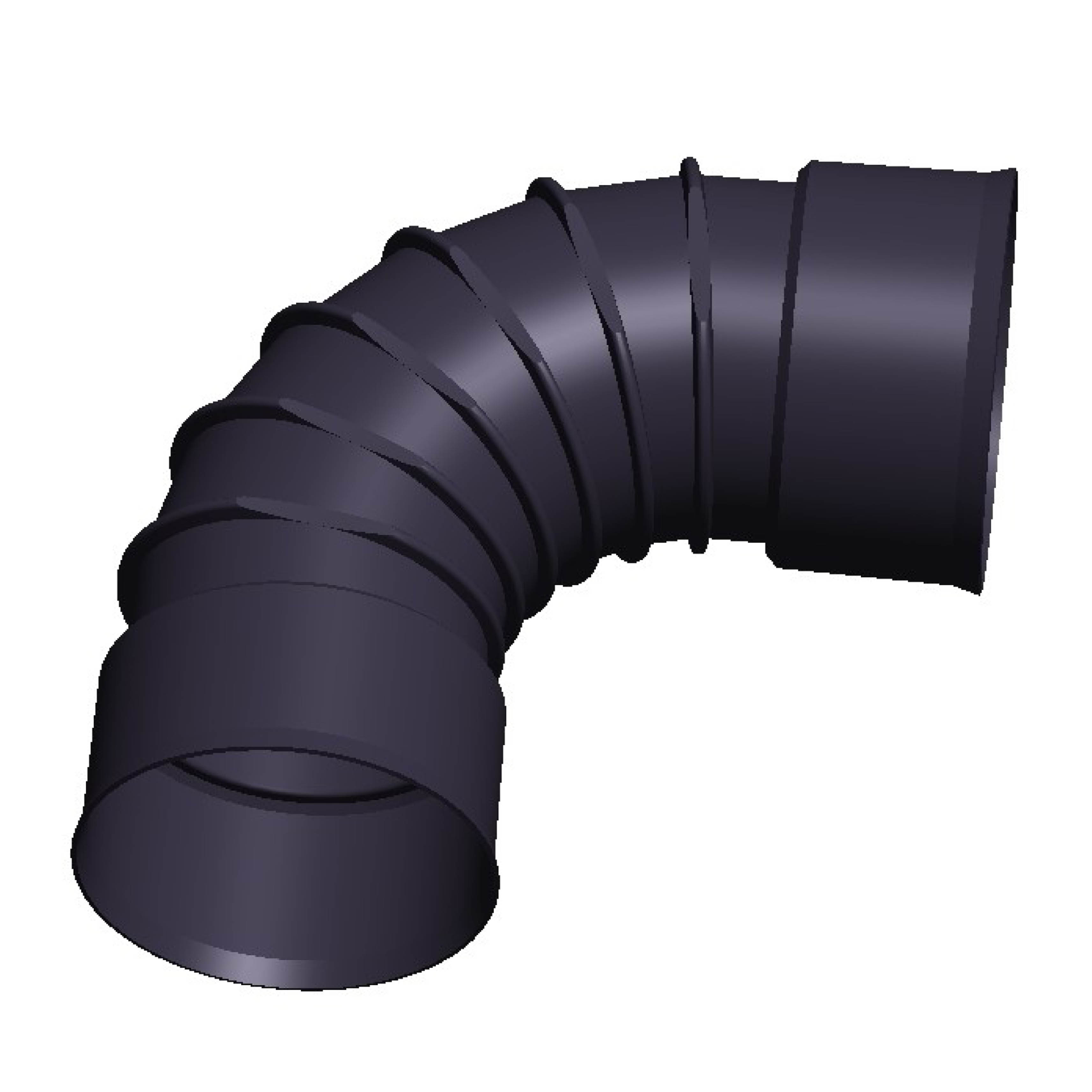

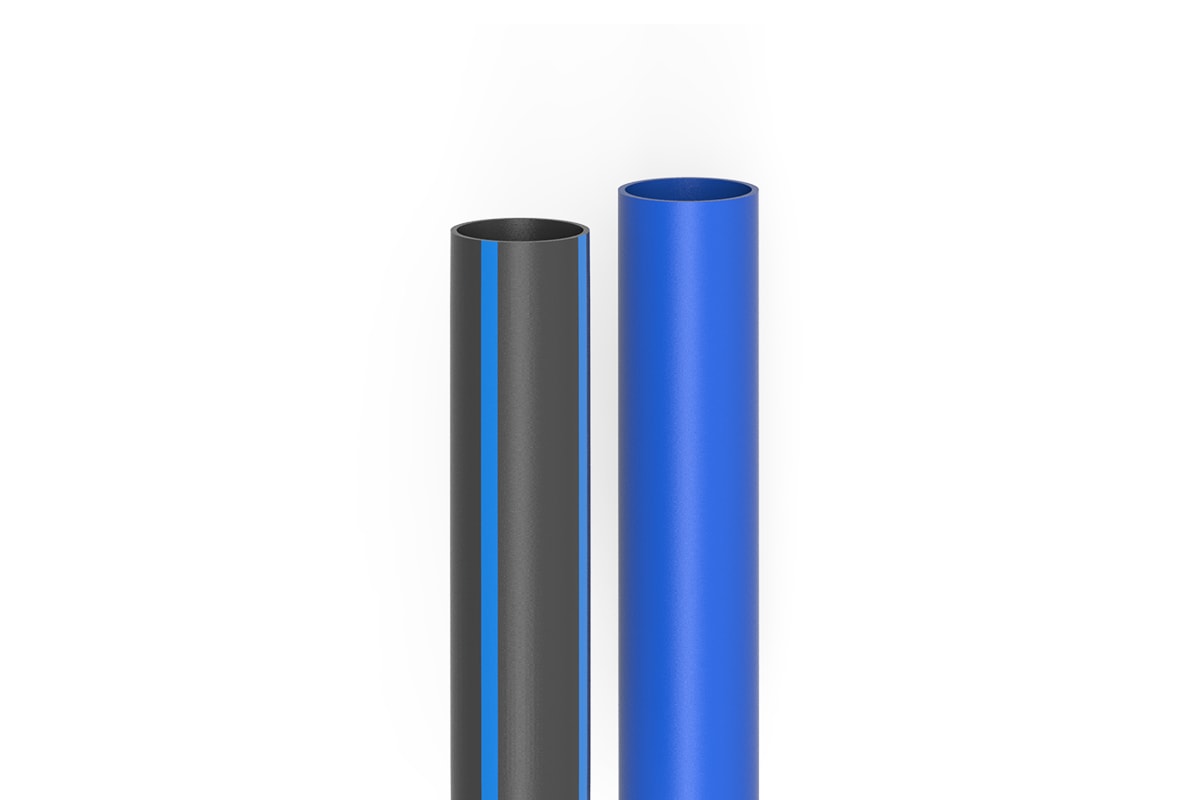

PE-STEEL transition fittings, consisting of a SDR11 polyethylene sleeve (PE100) in accordance with UNI EN 1555 (for gas) or UNI EN 12201 (for water) standards which is suitable for the connection with PE 100 pipes (S5 for gas – PN16 for water) + a steel sleeve made of pipes in accordance with UNI 8863 standard, galvanised on the inside and with male threaded end or suitable for the welding connection. These fittings are used for underground fluids distribution systems (usually PE) which become above ground systems. These last ones are preferred to be made of steel for the advanced mechanical characteristics of impact resistance (accidents or acts of vandalism). The range of shapes includes: straight or elbow (45°- 90°). Transition fittings of PE-BRASS are available too.

MAIN FEATURES

Safety

Wide range of professional choices

Lightness

Practicality