MAGNUM – HDPE pipe for non pressure underground systems SN4/SN8

BRIEF DESCRIPTION

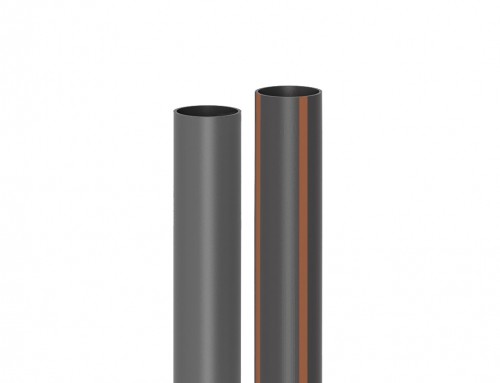

Double wall corrugated pipes made of high density polyethylene (HDPE) with a smooth inner surface and a corrugated outer one, available in black colour.

The Outer Diameter (OD) goes from 125 up to 1200 mm, while the Inner Diameter (ID) goes from 250 up to 1000 mm. Pipes are delivered in bars.

MAIN FEATURES

Wide range of diameters

Ring stiffness: SN 4-8

Smooth on the inside and corrugated on the outside

Socket or coupling connections with double sealing gasket

Lightweight and easy installation

High chemical and abrasion resistance

Inert to stray currents

Recyclable

This post is also available in: Italian French

CERTIFICATES:

ITALIANA CORRUGATI

BureauVeritas Magnum Italcor PE

Bureau Veritas - Magnum Italcor PP

IIP Cert.n°2004 Rev.0_Italcor Magnum

IIP Cert.n°2006 Rev.0_Italcor Magnum

PIIP Cert.n°2003 Rev.0_tipo B Magnum

PIIP Cert.n°2001 Rev.0 tipo B Magnum