INFINITANK LOW LOAD ACTIVATED SLUDGE TREATMENT

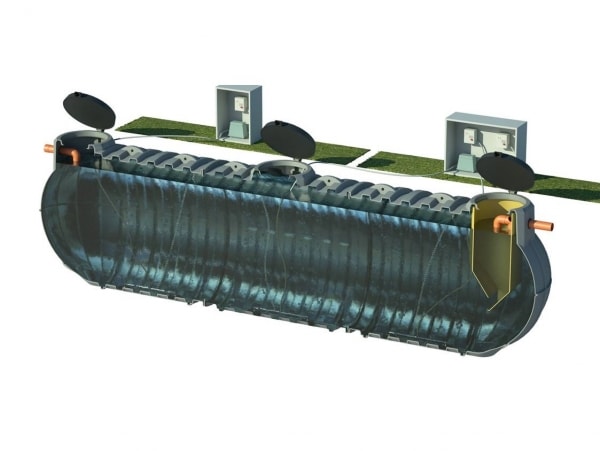

Material: modular tank for underground installation and separator in linear high-density polyethylene (LLDPE). Fitted with inlet and outlet pipe in PVC, blowers and micropore plate for air distribution.

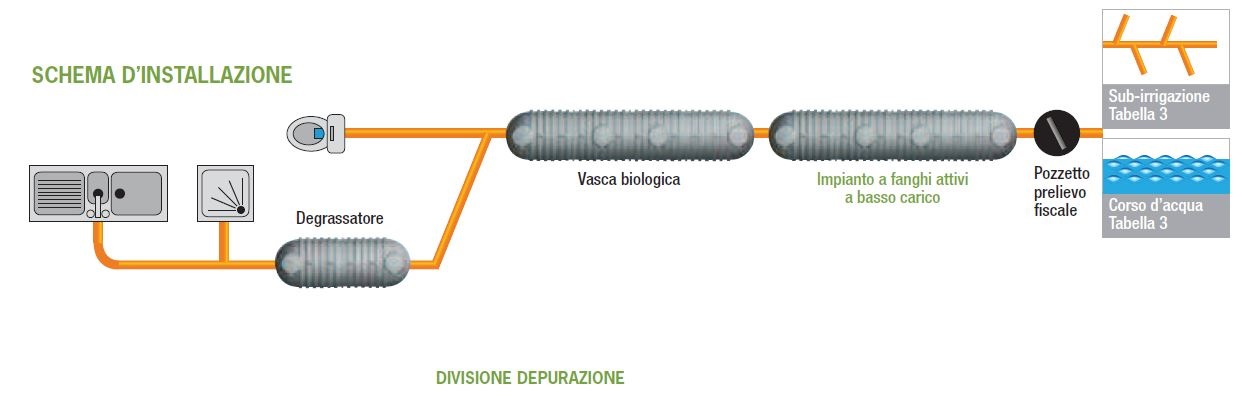

Application: treatment of domestic wastewater by means of primary sedimentation and anaerobic digestion of sludge in biological tanks and subsequent secondary activated sludge aerobic digestion. Rototec’s treatment plant is sized for an average domestic effluent with a daily load factor of 200 l/AE and a daily organic pollution of 60gBOD/AE per person. The inlet concentration is assumed to be of 240 mgBOD/l and providing a primary treatment of type Imhoff or septic tank upstream of the plant. It is of major importance to separate oils and foams upstream of the activated sludge tank as they could adversely affect the treatment efficiency which accounts up to 90% under regular conditions (percentage of reduction of the organic load as per BOD5).

Use and maintenance: it is advisable to inspect the tank at least once a year and to proceed with any necessary extraction of the excess sludge. These operations are usually performed in combination with the inspection and purge of the primary treatments (oil separator and organic tank). The cleaning will be performed by extracting a part of the excess sludge, removing accumulations on inlet and outlet pipes and cleaning the air diffusers in order to prevent possible clogging. Periodically check the operation of the blowers-compressors.

Carefully follow the “INFINITANK INSTALLATION INSTRUCTIONS” supplied by ROTOTEC.

This post is also available in: Italian French