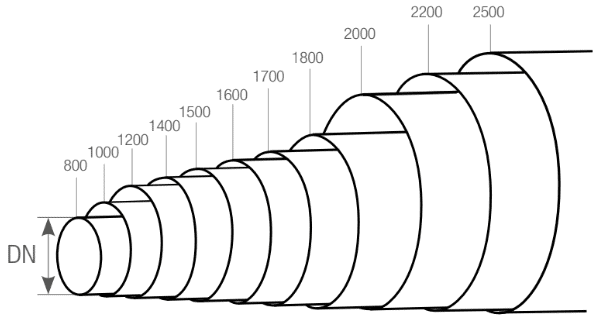

CorPress – double shell mechanical joint for corrugated pipes with high sealing performances

BRIEF DESCRIPTION

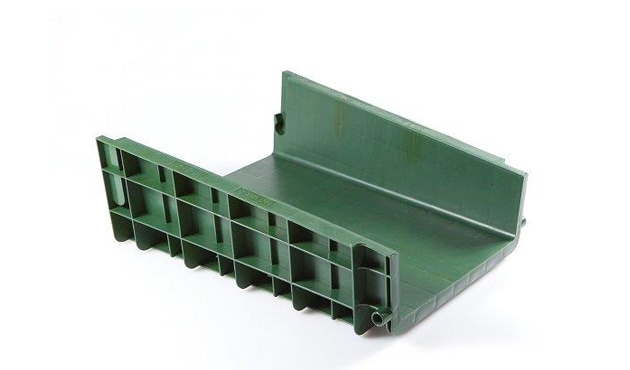

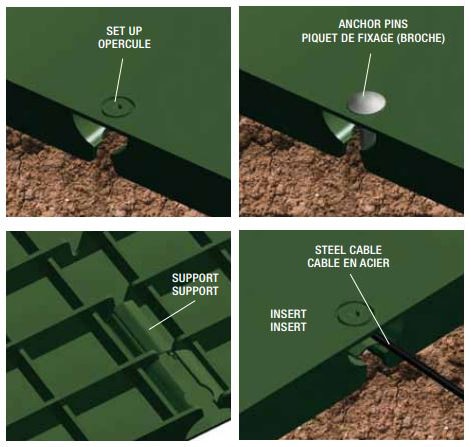

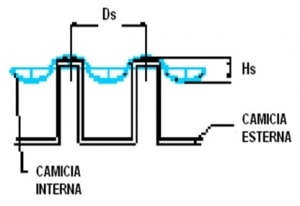

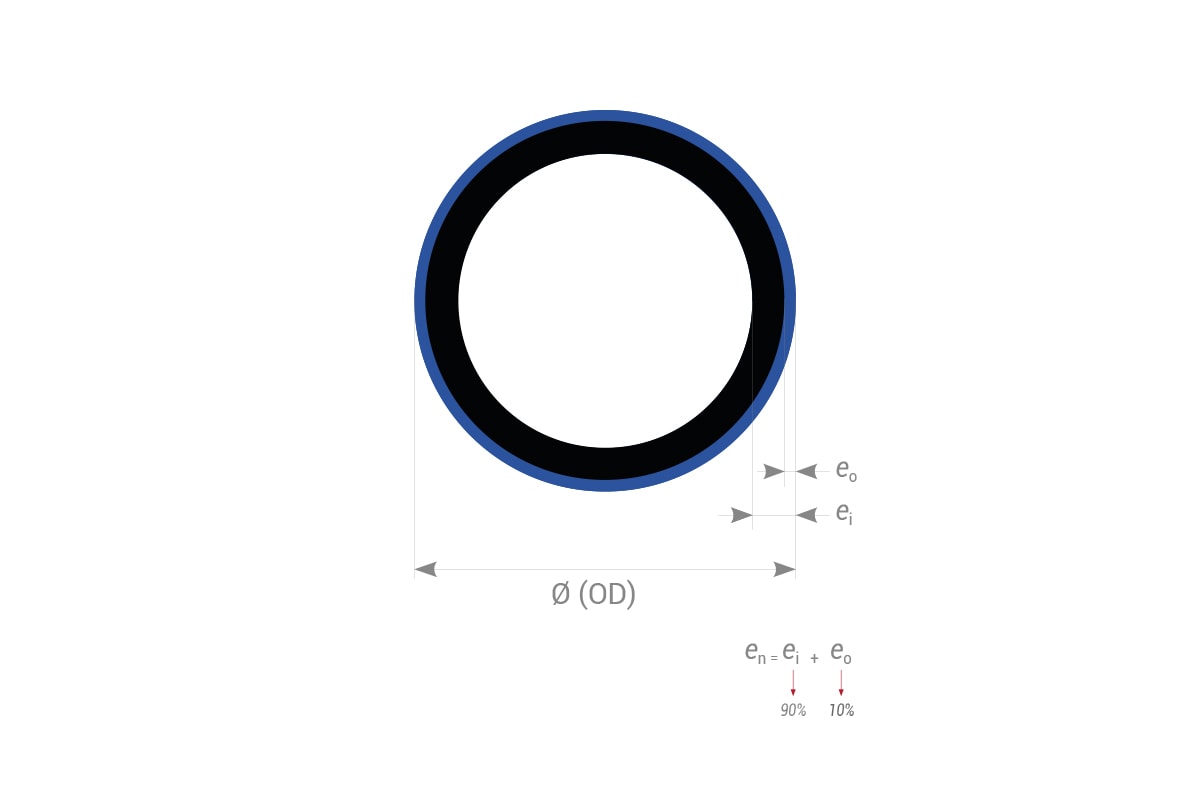

Mechanical double-shell joint with high-performance gasket for corrugated pipes (in PE and PP). The outer part is made of polypropylene (PP), while the inner surface is made of TPE, designed to adhere to the entire corrugated outer surface of the pipes to be connected. This enhances the hydraulic sealing performance compared to traditional systems and adds additional pull-out resistance, which is particularly useful in certain applications and/or installation methods. The connection between the two shells that make up the joint is made on-site using stainless steel screws and bolts, which must be properly assembled and tightened according to the manufacturer’s specifications.

NOTE: The corrugated shape of the TPE inner wall of the CorPress joints has been designed and manufactured based on the external geometries of the corrugated pipes produced by the System Group companies mentioned in this product sheet. Therefore, no sealing guarantee can be provided if used on corrugated pipes produced by other manufacturers.

MAIN FEATURES

- High sealing reliability

- Easy installation

- Pull-out resistance function

- Formation of repair kits

- Suitable for vertical wall or overhead installations (e.g., bridges and viaducts)

- High impact absorption capacity