INFINITANK IMHOFF SEPTIC TANKS

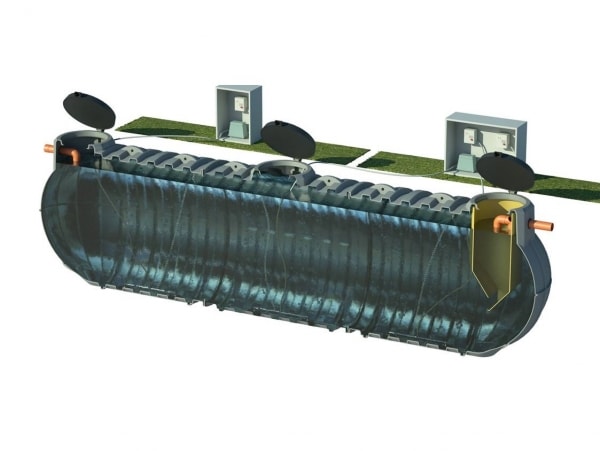

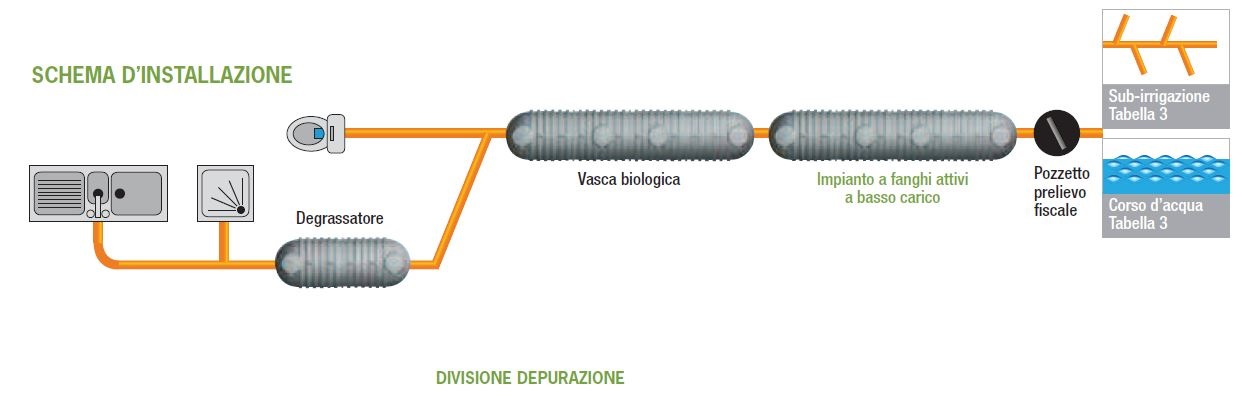

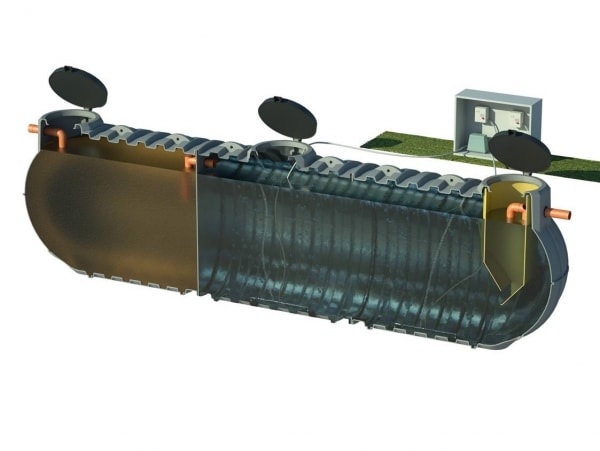

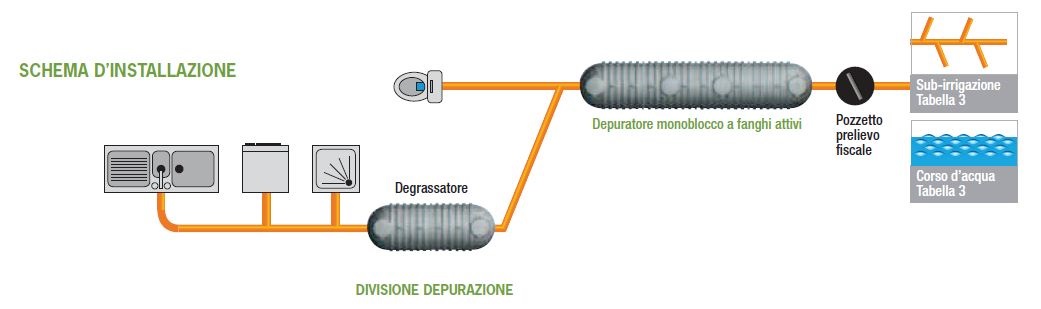

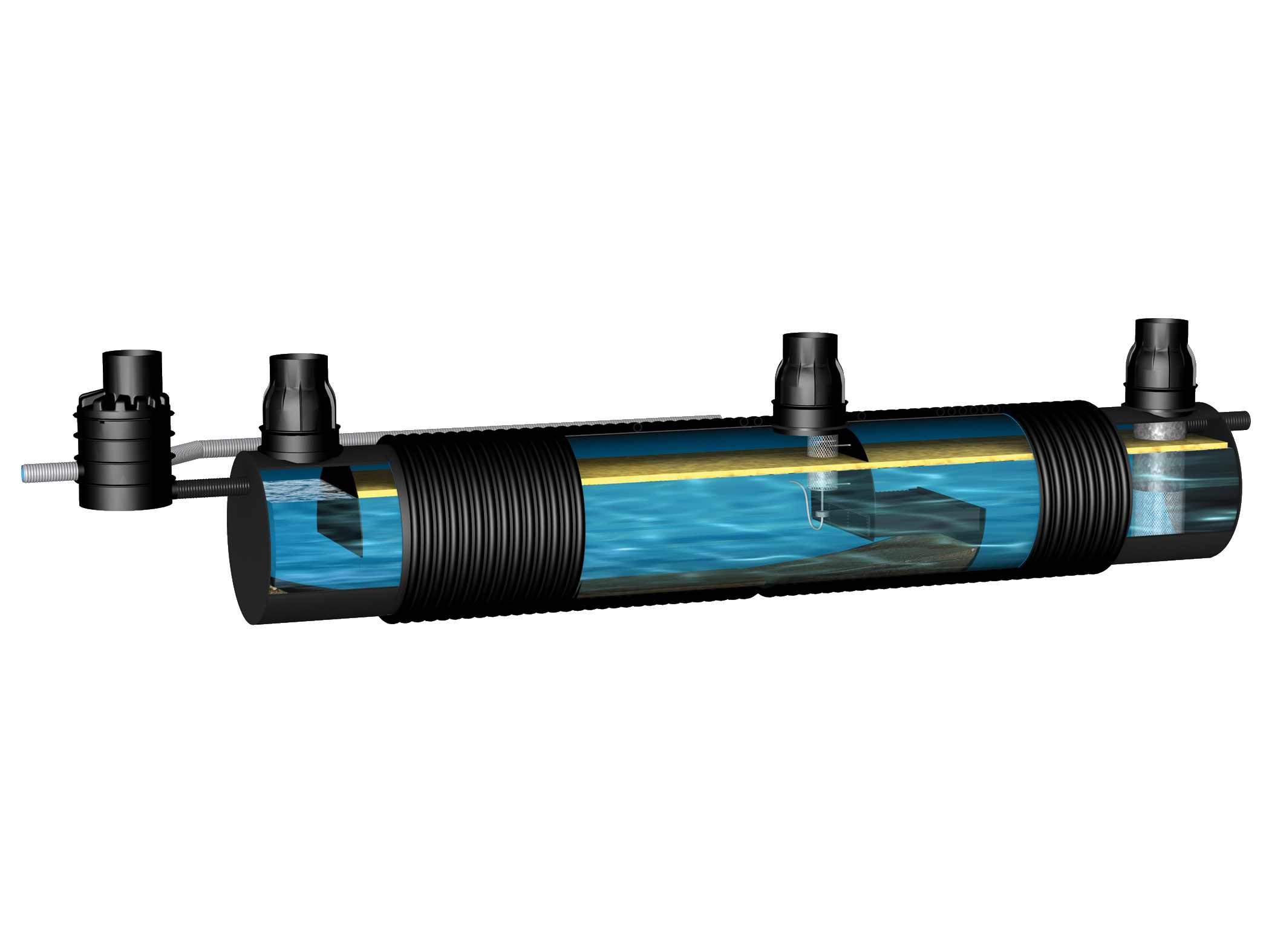

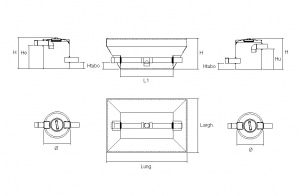

Material: corrugated underground container of modular type and sedimentation chamber in LLDPE with PVC inlet and outlet pipes. Manufactured according to standard UNI-EN 12566-3. The Legislative Decree n°152/2006 goes back to the Interministerial Committee on water protection (supplemento ordinario alla G.U. n. 48 del 21/02/77 par. 4), requiring average volumes of 40 I for the sedimentation chamber and of 100 l for the digestion compartment for underground civil wastewater. In the regional versions of Emilia Romagna and Umbria, the Imhoff tanks are sized according to D.G.R 1053/2003 (Emilia Romagna) and D.G.R. 1171/2007 (Umbria).

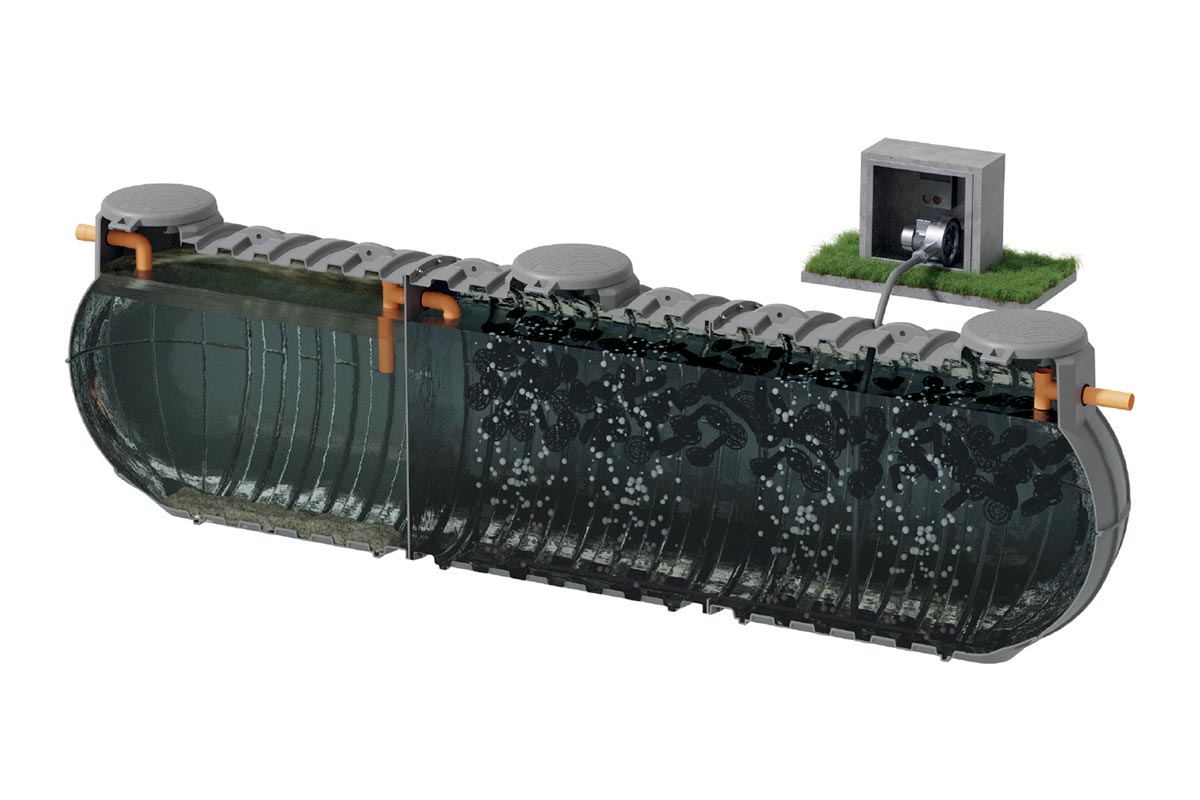

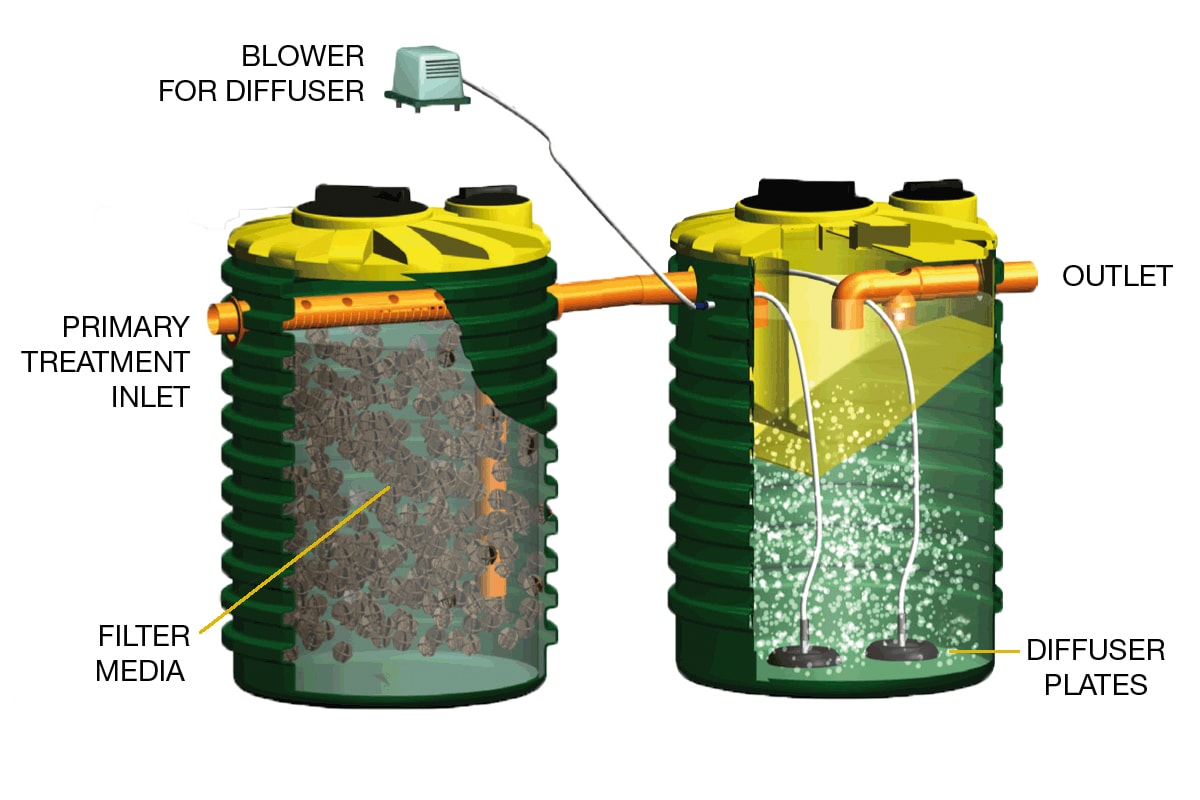

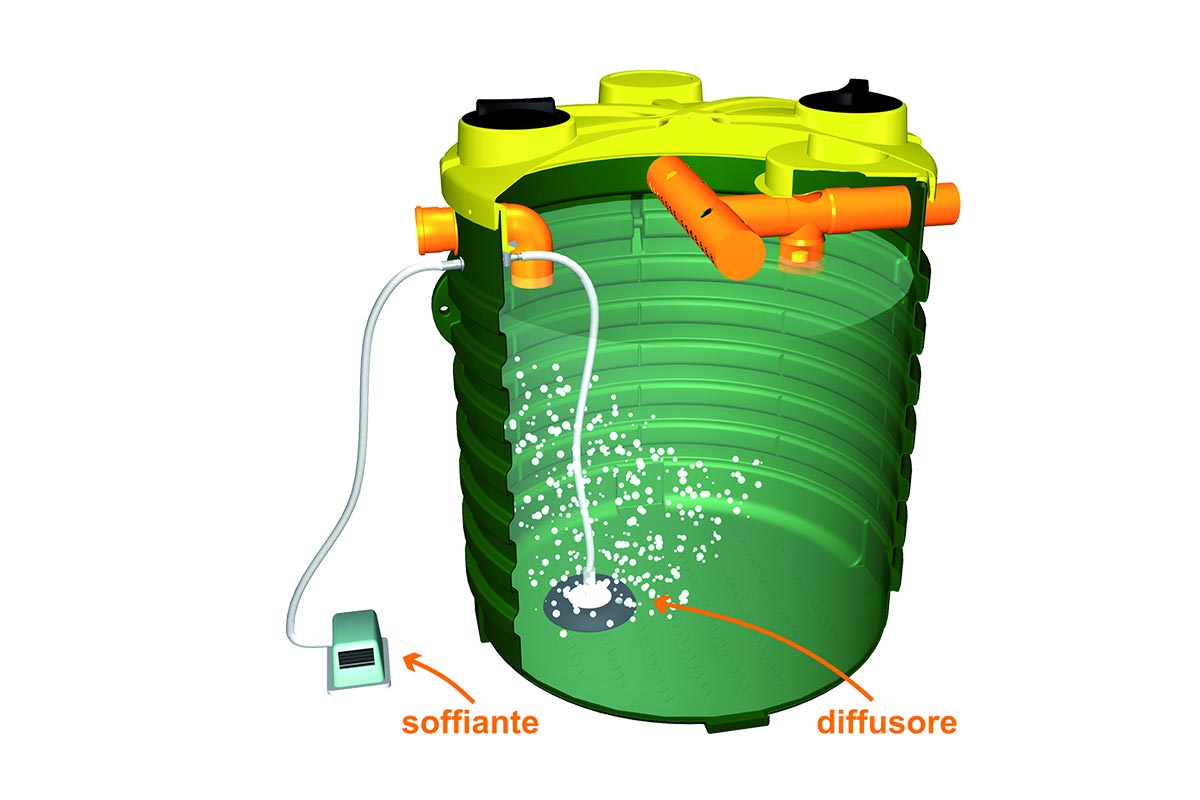

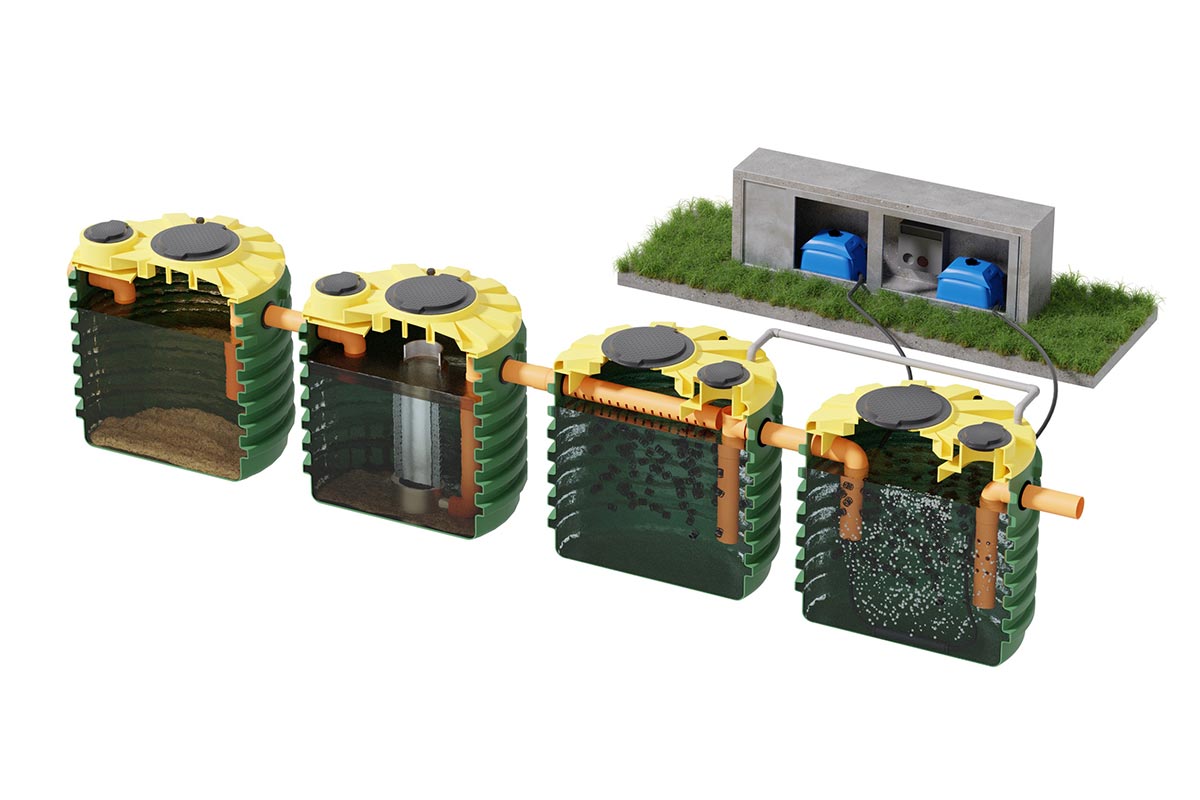

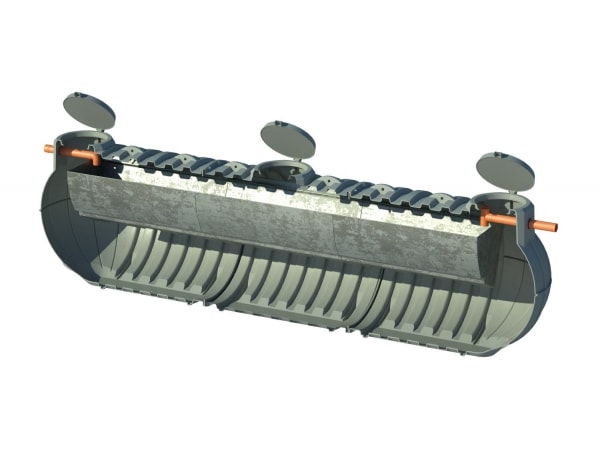

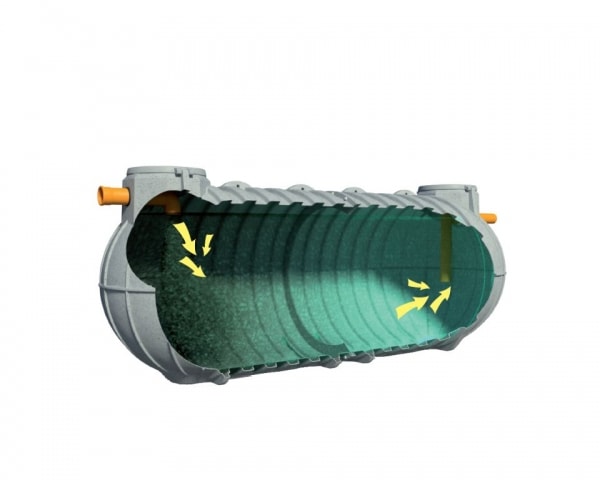

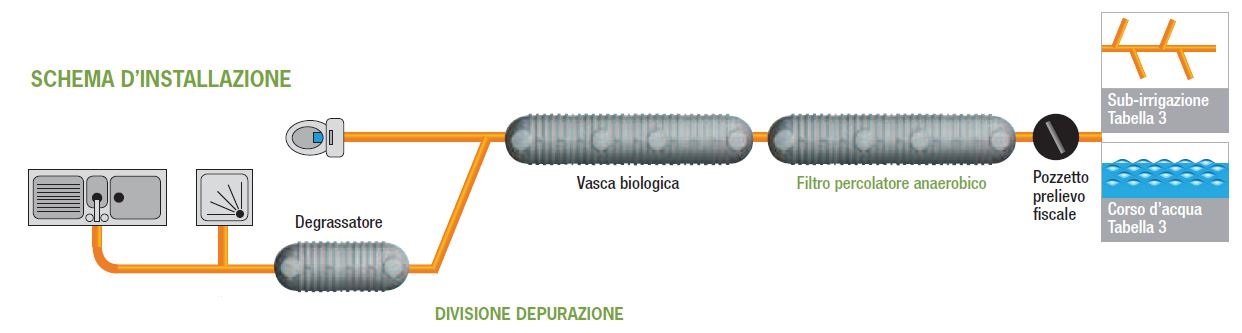

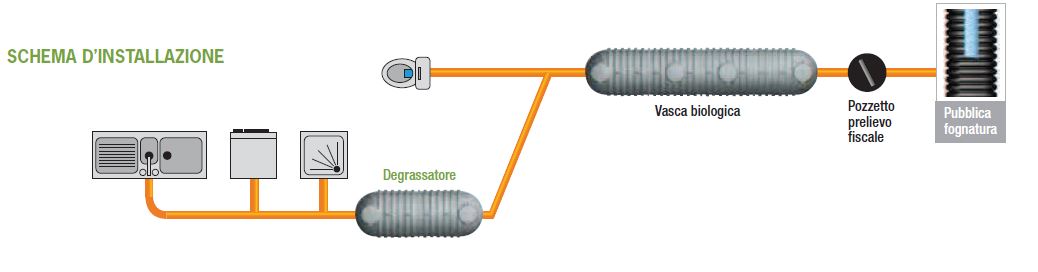

Application: purification of civil wastewater through primary sedimentation treatment and smudge biological digestion. This type of treatment also allows the simultaneous removal of 25-30% of the organic content, in terms of BOD5. Imhoff tanks consist of two overlapping and hydraulically communicating compartments. In the upper compartment, the sedimentable solids gravitate to the bottom of the sedimentation chamber, which has a suitable inclination to allow the sludge to pass to the lower compartment where it is digested. This type of plant makes use of the combined actions of a mechanical sedimentation process and a biological treatment of cold anaerobic digestion.

Use and maintenance: an excessive accumulation of putrescible material at the bottom of the tank can cause uncontrolled anaerobic digestion phenomena, leading to an over-production of biogas and the development of malodorous emissions. Furthermore, the reduction in the volume available in the digestion compartment and the excessive production of gas bubbles will cause the settled material to rise, thus causing deterioration in the quality of the treated effluent. The use of the Rototec BIO-ACTIVATOR is highly recommended for rendering the initiation of the biological processes more rapid, thus limiting the number of sludge removal operations and reducing the risk of malodorous emissions. The Imhoff tanks are designed to pro-vide primary sludge storage for a period of 6-8 months of plant operation. When sizing plant for Sensitive Areas, the frequency of sludge emptying operations is reduced to once every 12-14 months. A minimum of 1-2 inspections per year by qualified personnel and eventual emptying operations must be programmed according to the loads fed to the tank. Once the settled sludge has been removed, the internal surfaces of the tank must be cleaned in order to eliminate any material obstructing the effluent inlet and outlet pipes and the outlet of the sedimentation chamber.

Installation: please follow underground installation instructions provided by Rototec.