EMBRICE IN PE CANYON PER SCARPATE STRADALI

BRIEF DESCRIPTION

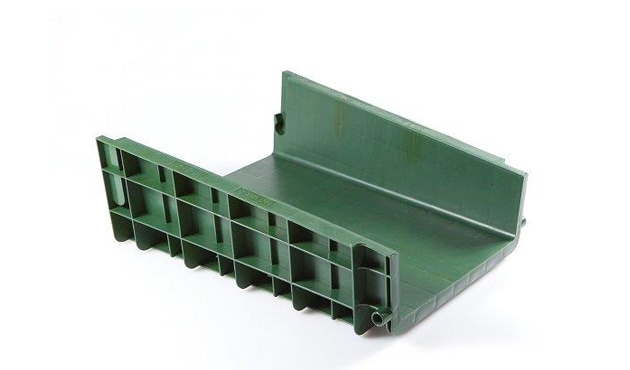

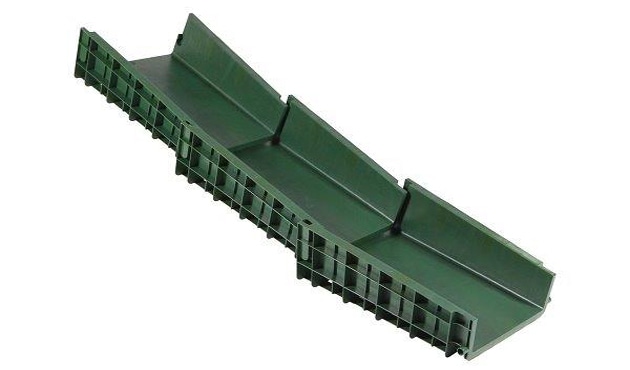

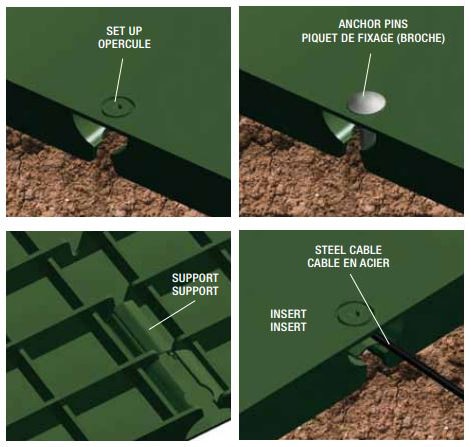

Polyethylene (PE) plain roofing tiles for liquids conveyance on high slope surfaces, such as roads and railways with embankments or landfill sites. They are available in green colour, provided with reinforcement lamellas on the outer surfaces which are useful for the improvement of the fixing in the laying ground; with double cylindrical pin connection that allows the height variation ± 20° and the thermal expansions absorption; with the predisposition to ground fixing through drift piling or steel cable.

MAIN FEATURES

Lightweight

Easy, fast and safe to handle and manual installation

Built-in interlocking connection system between the elements

High chemical and abrasion resistance

Recyclable

This post is also available in: Italian French