WASTEWATER MANAGEMENT TREATMENT

In order to prevent hydraulic and environmental risks, the Italian regions, after following the instructions of Ministry of the Environment and Land Protection, regulated and implemented the followings forms and cases:

(a) forms of control of rainwater run-off from separate sewerage systems;

(b) cases where special requirements may be required for discharge of stormwater run-off through separate pipelines, including, where applicable, the authorisation.

Rainwater not regulated in accordance with paragraph 1 shall not be subject to restrictions or prescriptions resulting from the third part of this decree.

The regions shall also regulate the cases in which it may be required first rainwater and water from outside areas. They must be conveyed and properly treated in sewage treatment plants for particular conditions. This is necessary for the activities carried out with the risk of leaking from uncovered impermeable surfaces of hazardous substances or substances that are detrimental to the achievement of the quality objectives of water entities.

However, the discharge or the release of rainwater directly into groundwater shall be prohibited.

HYDRAULIC AND ENVIRONMENTAL RISK MANAGEMENT WITH POLYETHYLENE STORAGE AND UNDERGROUND TREATMENT SYSTEMS.

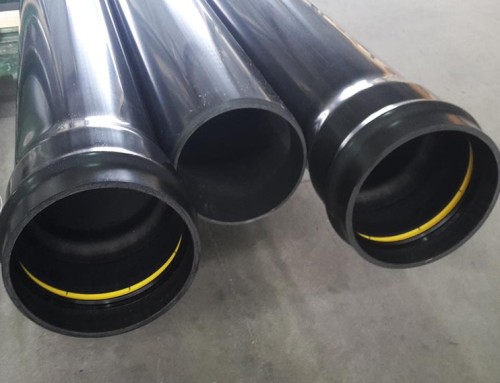

The modular systems composed by pipes are the result of the use of SPIRALED SGK POLYETHYLENE PIPES, which cover a production range from diam. 1000 to diam. 2500 mm.

The ELECTROFUSION welding junction system guarantees absolute uniformity between all elements and special parts. Curves, tees and manholes make the entire system homogeneous and adaptable to any functional and size requirements in the design field.

THE EASIEST WAY

Homogeneous system that can be adapted to any functional and space requirements in the design field.

LAYING phase:

- Laying according to standard UNI ENV 1046;

- Overlay thickness until 6 mt;

- Ring stiffness from SN2 to SN16;

- Vehicle Accessible;

- Suitable for laying in case of groundwater, with measures designed to prevent the floating pressures;

- Homogeneous system adaptable to any functional and space requirement in the design phase.

The most suitable method to counteract the presence of groundwater pressure, is to ensure an adequate cover thickness that allows to obtain the safety margin established by design, according to functional and dimensional requirements.

SOLUTIONS FOR RAINWATER STORAGE SYSTEMS

SGK as storage system: a real case-study

Taking into account the technical document talking about the realisation for a rainwater storage system, a few interesting tips are included:

- Quick installation;

- Easy tank maintenance;

- Durability of the work.

DESIGNER’S RECOMMENDATIONS

The rainwater tank will be realized with HDPE big diameters pipes with a structured wall profile, ring stiffness SN4 and with an internal diameter of 2500 mm. These pipes will be laid with a complete gravel sub grade and backfill and with a bottom slope of 2%.

This type of tank has the following advantages:

- The realization phases (excavation, installation and laying of these big diameters pipes and backfilling operations) will take about a week, after which it will be possible to restore the road surface, with enormous advantages in respect of the viability of the area, inconvenience for the inhabitants and of safety;

- The cleaning system is made of a simple submarine pump that needs low maintenance that can be done by any professional worker in this sector;

- HDPE pipes are, let’s say everlasting and they do not need, as for the concrete, of particular conservative interventions during the years.

If you are interested in knowing more about SKG TANKS, please contact our internal technical department, dedicated to design support:

Otherwise send us a request to have additional information here:

This post is also available in: Italian