WASTEWATER TREATMENT PLANT

[Casablanca – Marocco]

The work realised in Casablanca (Marocco), it has been developed together with Lydec and our subsidiary Rototec, leader in wastewater treatment plants and not only. The main purpose of the project was to offer a biological solution, therefore natural, against the pollutants that are present in the wastewater, by breaking down the bacterial load and therefore to improve waste-water treatment in a specific area of the city of Casablanca with particular activity in the proximity of a Carrefour supermarket in the Dar Bouazza area.

Rototec: thanks to its in-house technical department specialised in the design of both standard and customised wastewater treatment plants, Rototec has carried out this pilot project for a wastewater treatment plant sized for a specific flow rate of 15,000 l.

The product which was agreed with the customer, it has been considered the most suitable for the complete satisfaction of needs, was Infinitank with a capacity of 15,000 l.

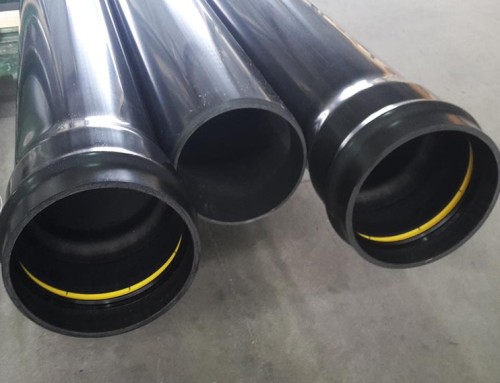

Rototec “Infinitank” tanks are in polyethylene (PE) tanks and these are made using rotational moulding technology, exclusively for underground. If several modules are connected together we can obtain large storage volumes.

Thanks to the possibility of using modules of various shapes, storage volumes can be created with morphologies that allow the best use use of available space.

In this case, the system integrates primary sedimentation and anaerobic digestion treatment of sewage sludge in a biological tank, as well as aerobic secondary treatment with activated sludge.

The connection between the various modules that make up a tank is made by a mechanical tightening system using screws and bolts, which guarantees mechanical stability to the tank, to which is added the electro-welding between the elements that guarantees a perfect and durable hydraulic seal.

Polyethylene is a non-toxic material that does not facilitate the development of algae in the liquids contained in the tanks, making them suitable for the containment of drinking water and other food substances. In addition, polyethylene can withstand high temperature changes (from -20 to + 80 °C) and is inert against chemical substances present in the soil.

For these reasons there are no problems of oxidation and corrosion on the material that can affect the mechanical characteristics and impermeability of the tanks.

In addition, polyethylene tanks, while guaranteeing the same functionality as other materials (cement, fibreglass, metal), are much lighter, making them extremely simple and economical to transport, install and maintain.

If you want to have more information, you can do it here=====> PRODUCT

This post is also available in: Italian