HD PE INSPECTION MANHOLES MADE WITH SPIRAL WALL PIPES BODY

Admin-2@tubiNet2022-02-15T14:59:30+01:00HD PE INSPECTION MANHOLES MADE WITH SPIRAL WALL PIPES BODY

BRIEF DESCRIPTION

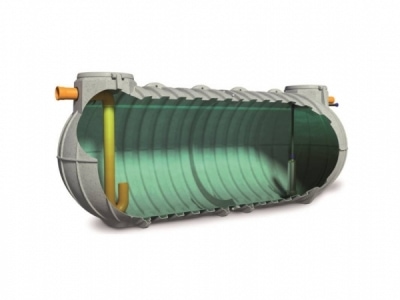

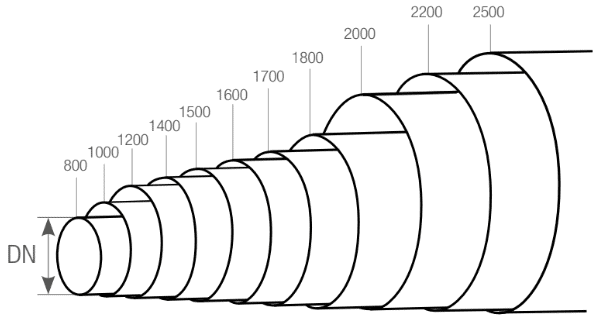

HDPE inspection manhole entirely black, consisting of a circular body obtained from a pipe built through the spiral wounding of a polyethylene profile technology. It can be smooth solid or structured, with smooth or profiled outer surface, with customised thicknesses that can be tapered on the outside. The base closing is made with a single or double plate of HDPE welded to the vertical body of the inspection manhole. The upper closing cap is provided with flat plates (with or without metallic structural reinforcements, depending on the sizes) and with manhole reductions, with or without the inner inspection stairs. The diameters range is between DN/ID 800 and 2500 mm, in order to allow the inspection of underground pipes or the placement of adjustment or raising components. There is the possibility to create in-line manholes, vertex manholes, intersection manholes and backdrop manholes. Modules are preassembled at the factory before the shipment through an extrusion welding made by qualified personnel, in order to make faster and easier the installation. Suitable for the connection of all plastic pipe types, both with solid or structured profiles, but also for other pipes. Suitable for applications in areas subject to heavy traffic, combined with an uptight plate for force distribution and in case of groundwater. Wide range of customisable shapes.

MAIN FEATURES

Monolithic quality (high reliability in case of groundwater)

Structural reliability

Lightweight

Easy and quick to install

Plastic behaviour in unstable situations

Wide range of solutions (sizing optimization)

Versatility

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

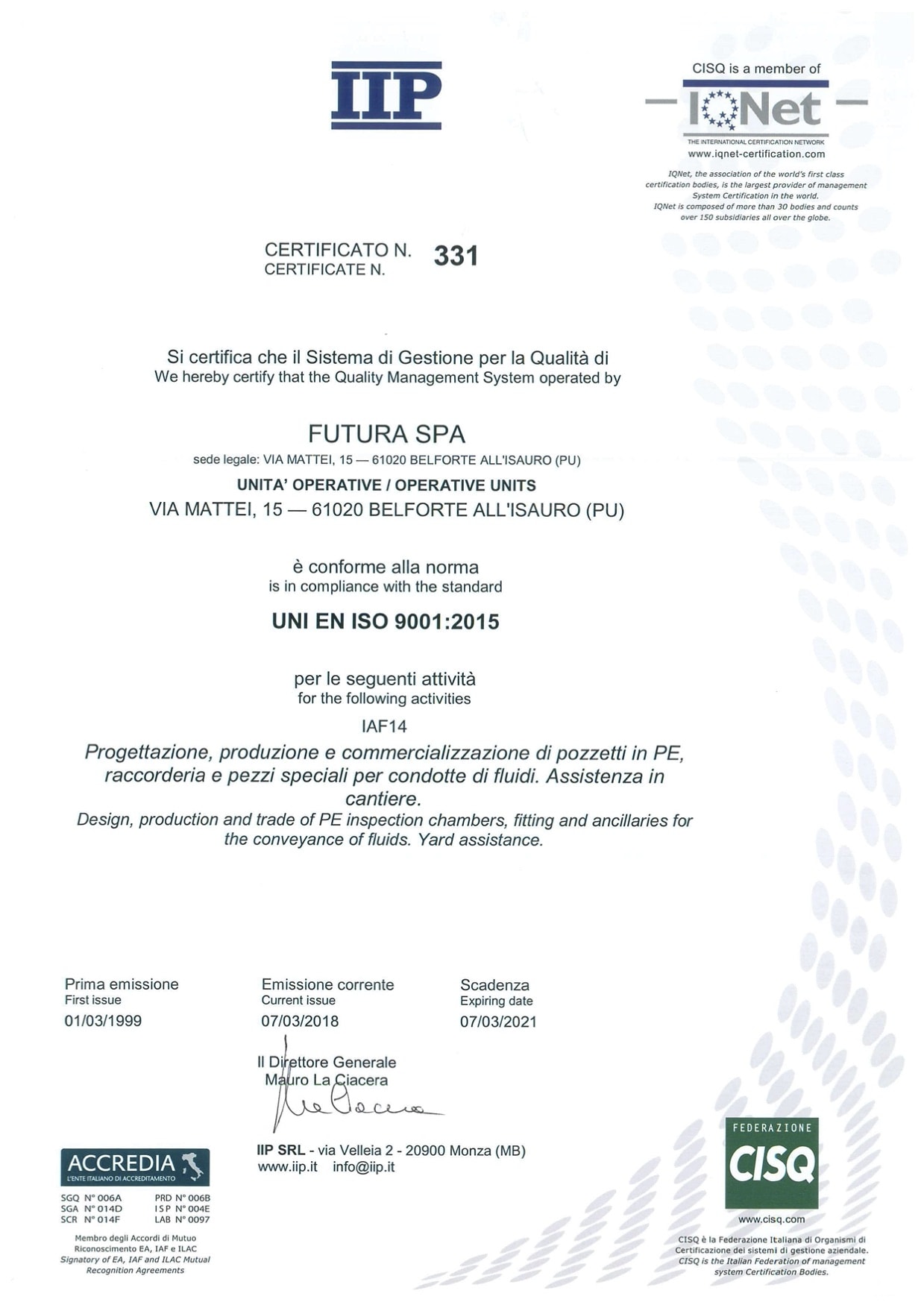

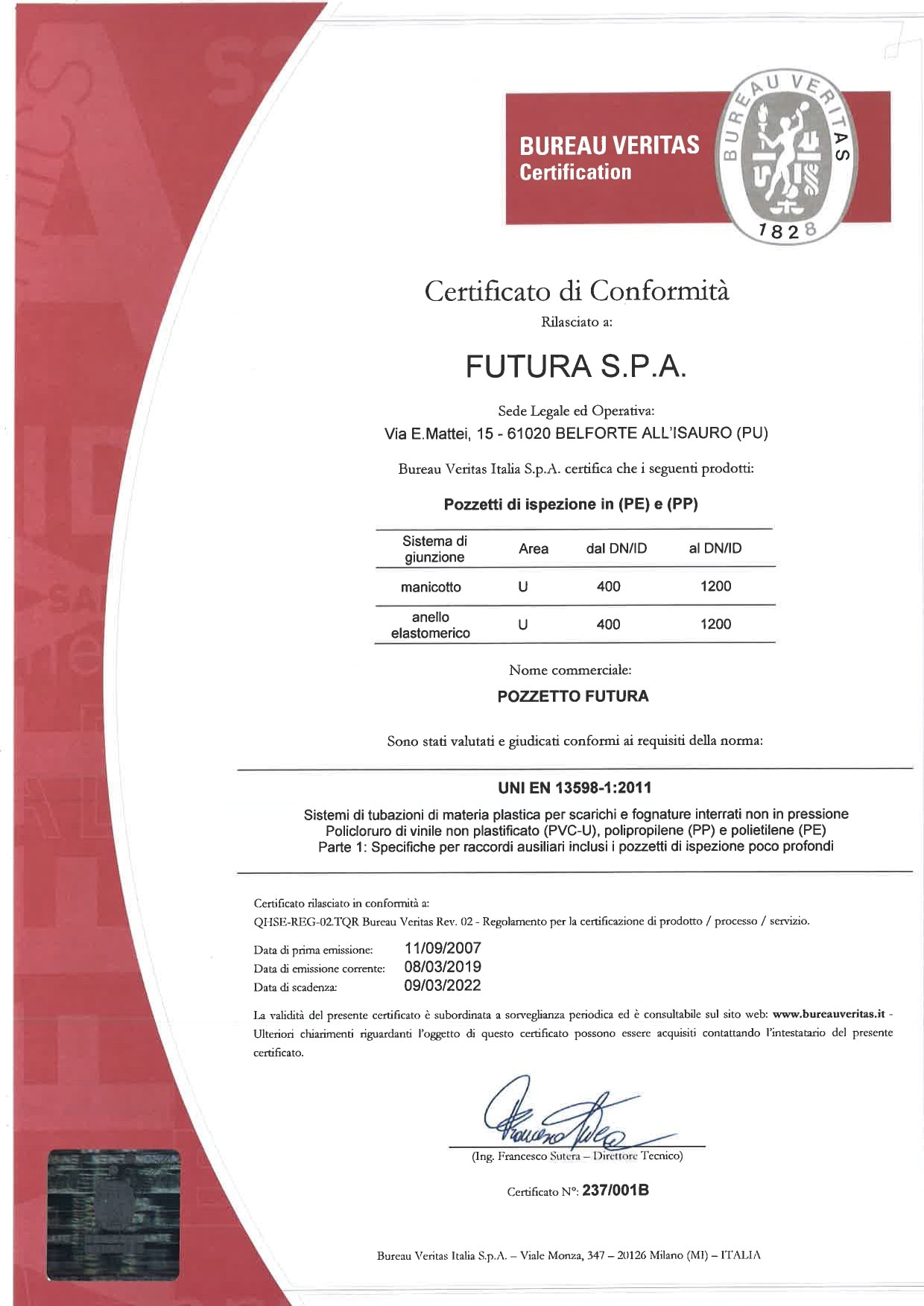

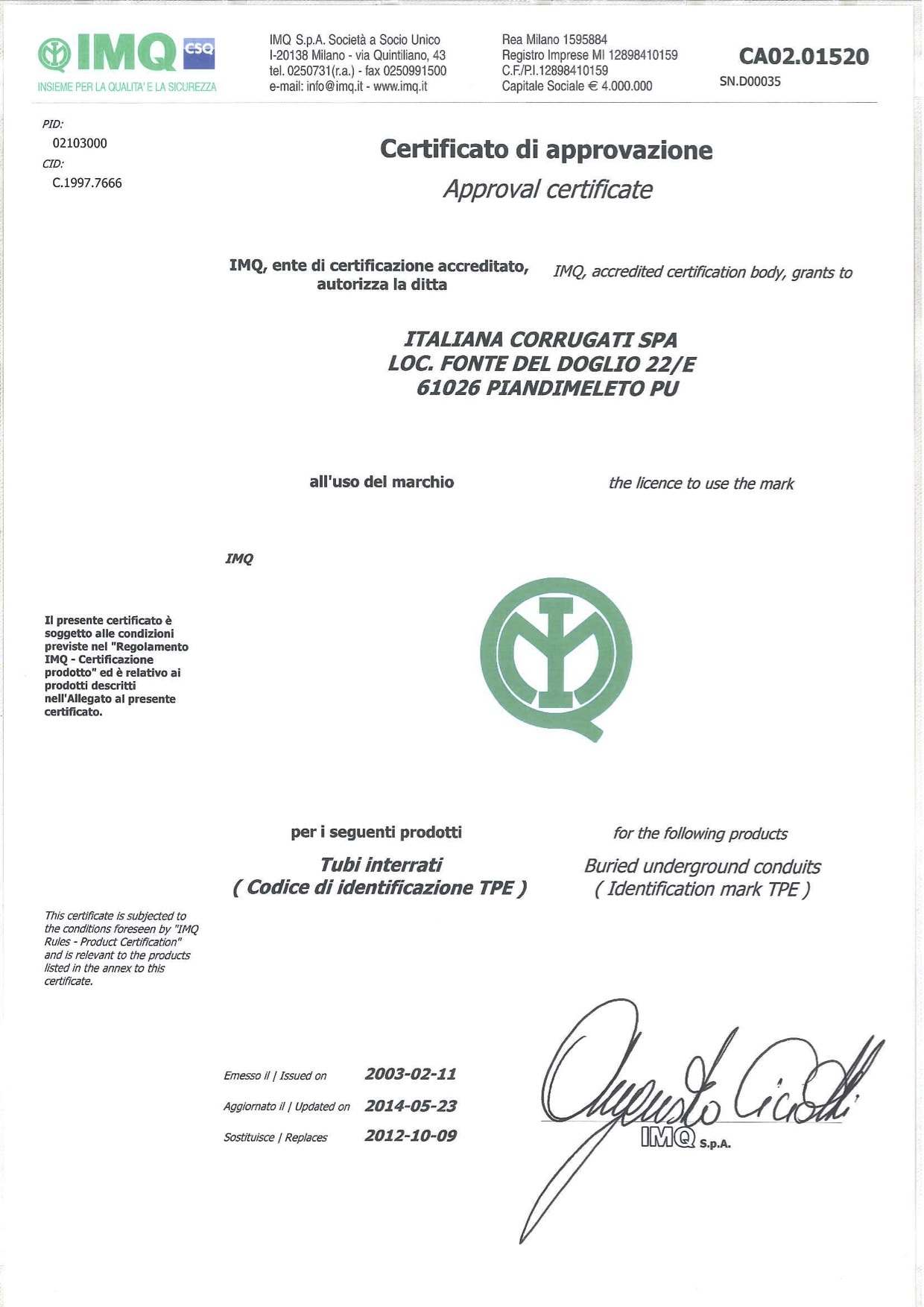

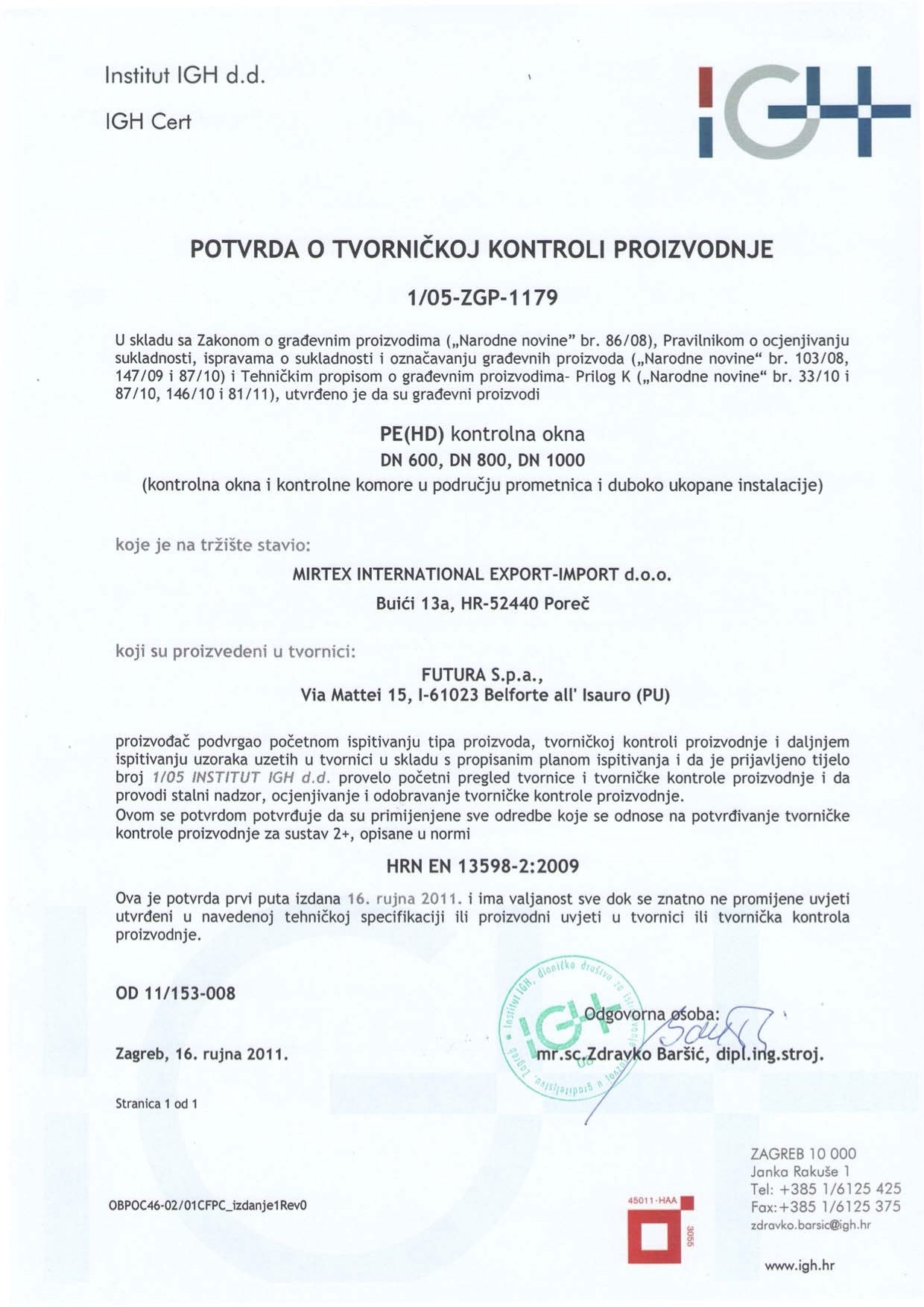

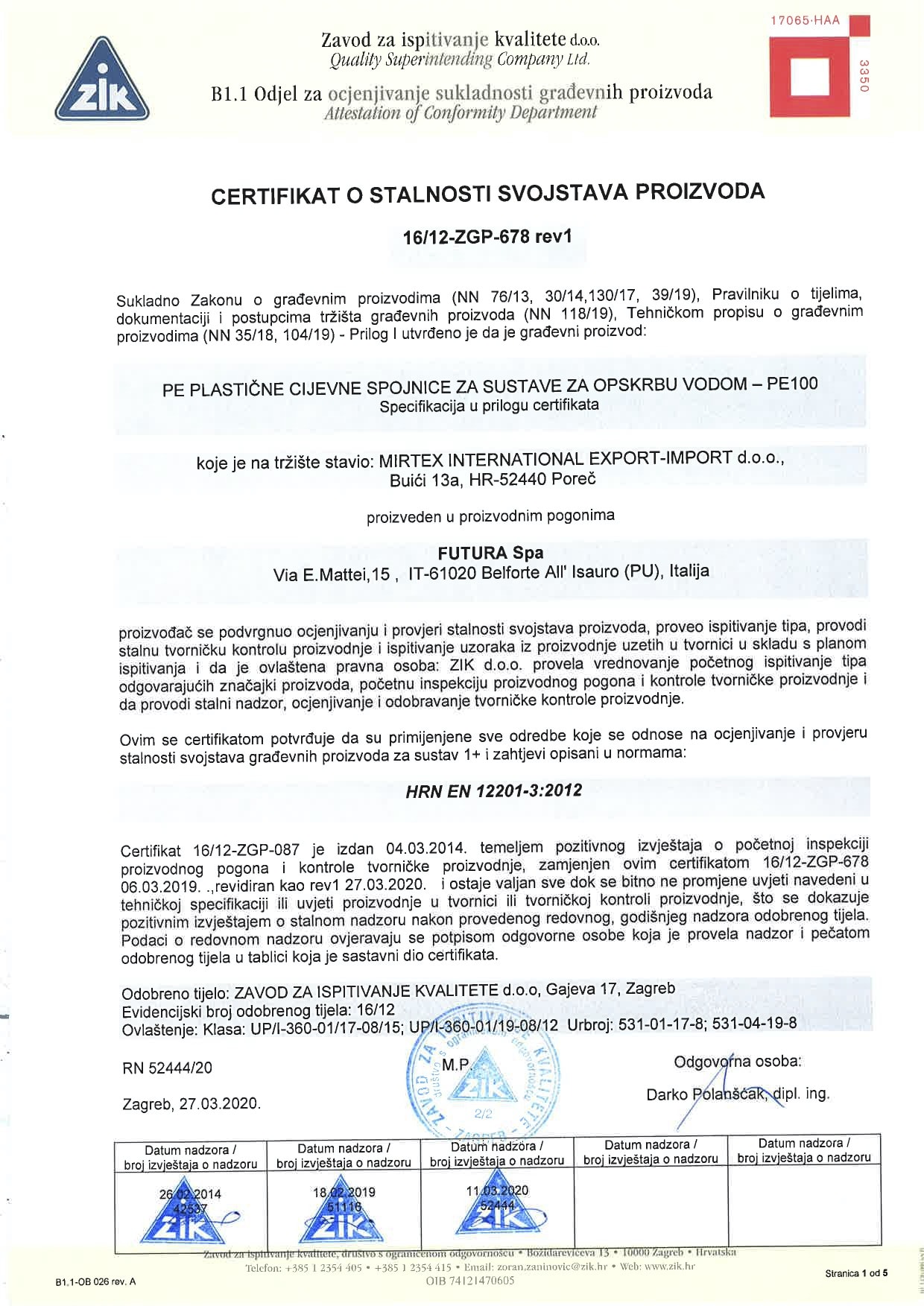

CERTIFICATES:

FUTURA

PE INSPECTION MANHOLES MADE WITH CORRUGATED PIPES BODY

Admin-2@tubiNet2022-02-15T15:01:06+01:00PE INSPECTION MANHOLES MADE WITH CORRUGATED PIPES BODY

BRIEF DESCRIPTION

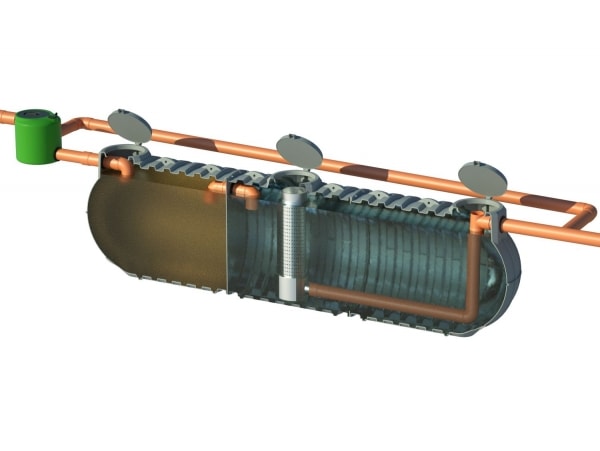

Circular manhole, made of multiple polyethylene (PE) modules, with bases and manhole reductions provided with a socket to accommodate the connection of the extension body made of corrugated pipe. The base can be made with a single or double flat plate. The manhole is available in black colour, with a diameters range that goes from DN 630 up to 1200 mm, in order to allow the inspection of underground pipes which are accessible with DN ≥ 800 mm. The modules allow the creation of in-line manholes, vertex manholes, intersection manholes and backdrop manholes. Modules are preassembled at the factory before the shipment through an extrusion connection made by qualified personnel, but they can also be assembled partially or entirely on the construction site through specific sealing gaskets. The manholes used for inspections are provided with stairs (on request). Suitable for connecting all plastic pipes, but also the stoneware ones. Suitable for applications in areas subject to heavy traffic, combined with an uptight plate for force distribution, for heights of ≤ 5 m and groundwater heights of ≤ 2 m. The wide range of individual modules shapes allows to create various standard modules, but with customised versions too.

MAIN FEATURES

100% permanent tightness

Structural reliability

Lightweight

High ring stiffness corrugated body

Base can be made with a single or double flat plate

Easy and quick to install

Plastic behaviour in unstable situations

Wide range of solutions (sizing optimization)

Versatility

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

CERTIFICATES:

FUTURA

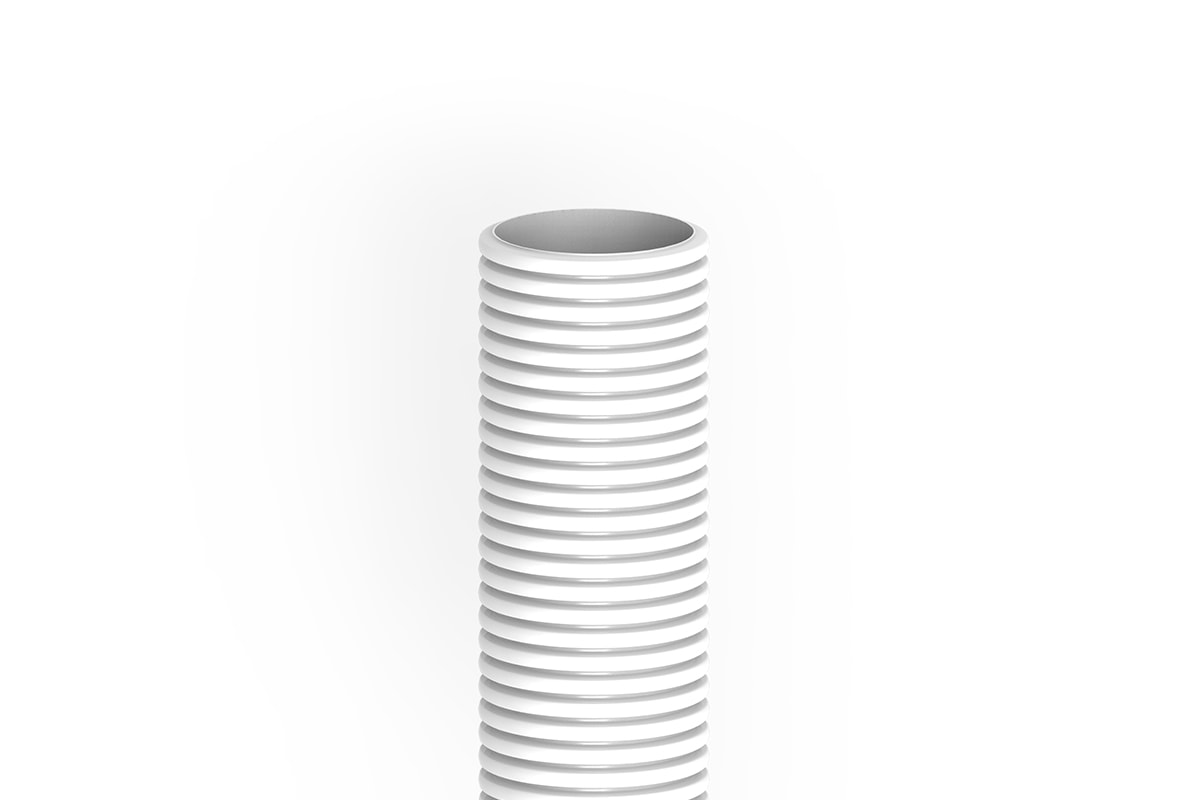

PE INSPECTION MANHOLES MADE WITH SMOOTH SOLID WALL PIPES BODY

Admin-2@tubiNet2022-02-15T15:02:26+01:00PE INSPECTION MANHOLES MADE WITH SMOOTH SOLID WALL PIPES BODY

BRIEF DESCRIPTION

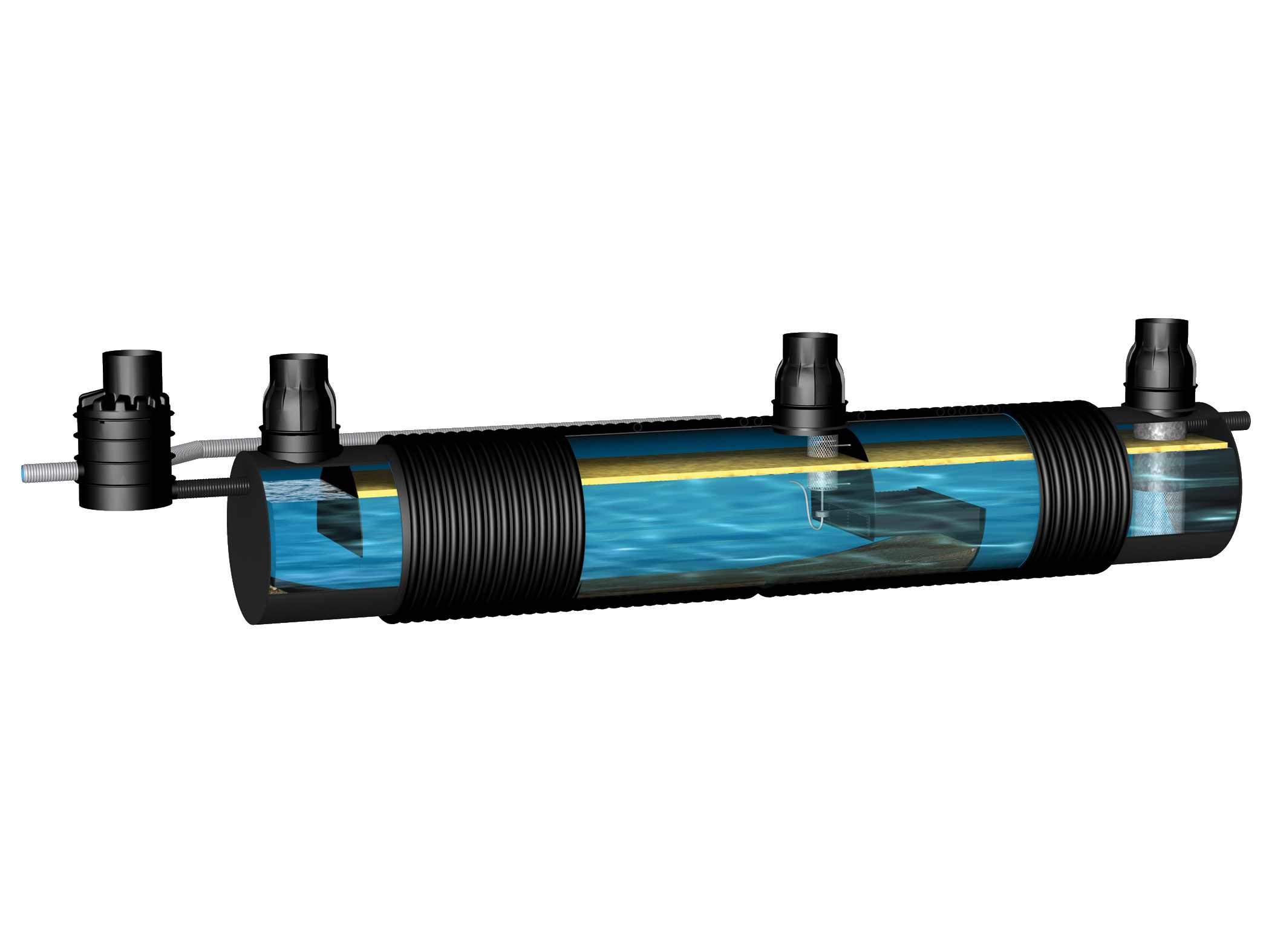

Circular manhole, made of multiple polyethylene (PE) modules, with bases consisting of flat plates (single or double), extension body consisting of solid wall pipe with smooth extruded surface of various thicknesses, and reductions to the manholes provided with socket in order to accommodate the connection of the extension body made of corrugated pipe, or made up of flat plates (with or without metallic structural reinforcement) and connection of the element of manhole reduction. Modules are available in black colour with a diameters range that goes from DN 630 up to 2500 mm, in order to allow the inspection of underground pipes which are accessible with DN/ID ≥ 800 mm. They allow the creation of in-line manholes, vertex manholes, intersection manholes and backdrop manholes. Modules are preassembled at the factory before the shipment through an extrusion connection made by qualified personnel. The manholes used for inspections are provided with stairs (on request). Suitable for connecting all plastic pipes, with structured or solid walls, but also the stoneware ones. Suitable for applications in areas subject to heavy traffic, combined with an uptight plate for force distribution and in case of groundwater. Wide range of customised shapes.

MAIN FEATURES

Monolithic quality (high reliability in case of groundwater)

Structural reliability

Lightweight

Easy and quick to install

Plastic behaviour in unstable situations

Wide range of solutions (sizing optimization)

Versatility

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

CERTIFICATES:

FUTURA

PE MANHOLES FOR INSPECTION OF BURIED PIPES

Admin-2@tubiNet2022-09-07T12:35:07+02:00PE MANHOLES FOR INSPECTION OF BURIED PIPES

BRIEF DESCRIPTION

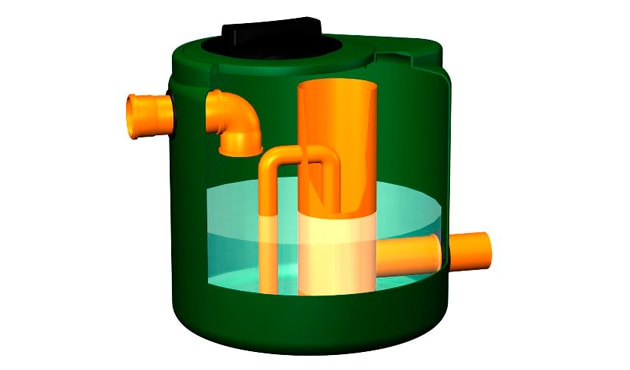

Circular manhole, preassembled with multiple polyethylene (PE) modules for bases, extensions and manhole reductions. It is available in black colour, and the diameters range goes from DN 400 up to 1200 mm , in order to allow the inspection of underground pipes which are accessible with DN ≥ 800 mm. The modules allow the creation of in-line manholes, vertex manholes, intersection manholes and backdrop manholes. Modules are preassembled at the factory before the shipment through an extrusion connection made by qualified personnel, but they can also be assembled partially or entirely on the construction site through specific sealing gaskets. The manholes used for inspections are provided with stairs which are in accordance with the EN 13101 standard (they are detachable upon request). Suitable for connecting all plastic pipes, but also the stoneware ones. Suitable for applications in areas subject to heavy traffic, combined with an uptight plate for force distribution, for heights of ≤ 5 m and groundwater heights of ≤ 2 m. The wide range of individual modules shapes allows to create various standard modules, but with customised versions too.

MAIN FEATURES

100% permanent tightness

Structural reliability

Lightweight

Easy and quick to install

Plastic behaviour in unstable situations

Wide range of solutions (sizing optimization)

Versatility

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

CERTIFICATES:

Valve Boxes For Irrigation

Admin-2@tubiNet2021-07-22T13:31:53+02:00VALVE BOXES FOR IRRIGATION

BRIEF DESCRIPTION

Polyethylene valve boxes for irrigation systems, great for residential or landscaped applications. They are sturdy, lightweight and stackable, and have been developed in order to facilitate the laying operations and to make easier the installation processes. The holes for the pipes passage can be made by using a simple utility knife. The cover, which is available in green colour and with the typical anti-slip texture, is secured with common self-tapping screws made of stainless steel which can be removed by using a simple screwdriver. The cover has a provision for being drilled in order to install a lighting column which is located inside the box thanks to the specific pole-carrier accessory.

MAIN FEATURES

Toughness

Lightweight

Stackable

Easy and quick to install

UV resistance

Provision for pipes and lighting columns

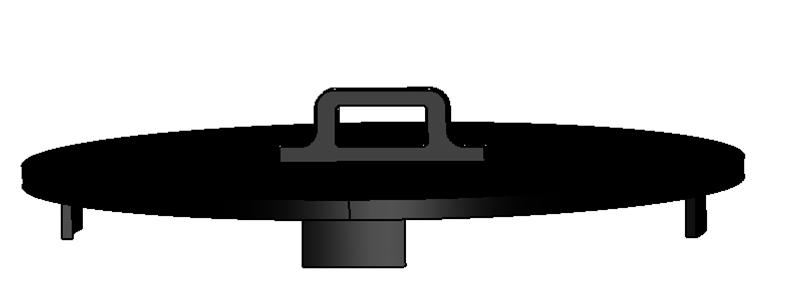

PE REMOVABLE COVER FOR INSPECTION MANHOLE ACCESS

Admin-2@tubiNet2021-07-22T13:37:51+02:00PE REMOVABLE COVER FOR INSPECTION MANHOLE ACCESS

BRIEF DESCRIPTION

Manhole cover made of high density polyethylene (HDPE), consisting of a closing plate provided with an external handle for movement and extraction + 4 centring elements on the inner surface, for closing the inspection entrances of every measurement without tightness need.

MAIN FEATURES

100% PE

High chemical resistance

Lightness, speed and convenience of installation and removal

Customised shapes and sizes

Inert to stray currents

Recyclable

PE WALKABLE MANHOLE COVER

Admin-2@tubiNet2021-07-22T13:35:25+02:00PE WALKABLE MANHOLE COVER

BRIEF DESCRIPTION

Moulded manhole cover, provided with 4 points for fixing by using screws and bolts, in order to close the entrances of the circular inspection manholes of DN 600 mm. A sealing gasket of EPDM can be located in order to guarantee the tightness performance of outer liquids permeation.

MAIN FEATURES

100% PE (clamping screws excluded)

Stainless steel screws upon request

High chemical resistance

Lightweight and quick to install

Easy to remove in case of maintenance operations

Inert to stray currents

Recyclable

PE Flanged Cover

Admin-2@tubiNet2021-07-22T13:16:49+02:00PE FLANGER COVER

BRIEF DESCRIPTION

Flanged cover made of high density polyethylene (HDPE), which consists of a flange welded on a cylindrical element made of HDPE (as the top of inspections or pipes) + closing blind flange, and a specific EPDM sealing gasket is placed between the two flanges. Both flanges are provided with matching holes (D= 18 mm) for the connection through screws (M16 x 70 mm) and corresponding bolts, for inspection accesses with a guarantee on gas and liquid tightness without pressure.

MAIN FEATURES

Made entirely of PE (except for the locking screws)

Stainless steel screws on demand

High chemical resistance

Completely tight

Lightweight and quick to install

Inert to stray currents

Recyclable

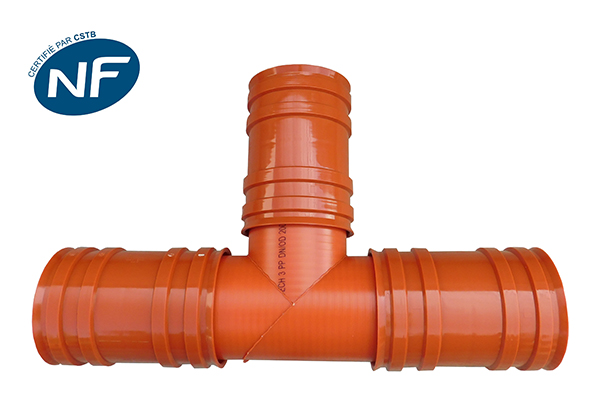

TECH3 – fittings for PP triple wall structured pipes

Admin-2@tubiNet2021-07-22T11:51:16+02:00TECH3 – fittings for PP triple wall structured pipes

BRIEF DESCRIPTION

Segmented fittings for structured triple wall profile pipes made of polypropylene (PP), with or without connecting sleeve with double sealing gasket and an anti-slip device. They find application in non-pressure networks.

MAIN FEATURES

Triple wall (high tolerance to point loads)

High ring stiffness: SN ≥ 16

Socket or connecting sleeve with double sealing gasket with anti-slip device

Upon client’s request, fittings can be customised

Lightweight and easy to install

High chemical and abrasion resistance

Inert to stray currents

Recyclable

| Type | Angle | M/F | Diameter | Load Class |

|---|---|---|---|---|

BENDS

|

15° 15° 30° 30° 45° 45° 60° 60° 90° 90° |

M/F F/F M/F F/F M/F F/F M/F F/F M/F F/F |

125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 125 | 160 | 200 | 250 |

SN16 |

45˚ TEES

|

45° 45° |

MFF FFF |

125 | 160 | 200 | 250 125 | 160 | 200 | 250 |

SN16 |

TEES

|

90° 90° |

MFF FFF |

125 | 160 | 200 | 250 125 | 160 | 200 | 250 |

SN16 |

| REDUCING COUPLING

|

– | FF | 16.0-125 | 200-160 | 250-200 | SN16 |

CERTIFICATES:

PE male/male formed fittings for double wall corrugated pipes for Non-pressure networks

Admin-2@tubiNet2024-04-22T09:31:48+02:00MAGNUM M/M SEGMENTED FITTINGS

BRIEF DESCRIPTION

Fittings consisting of double wall corrugated pipes of high density polyethylene (HDPE), smooth on the inside and corrugated on the outside. They are available in black colour with customised or standard shapes and angles and with both “male” end joints. Couplings and gaskets on request.

MAIN FEATURES

Wide range of diameters and shapes

Fittings can be customised

Ring stiffness: SN 4-8

Smooth on the inside and corrugated on the outside

Sleeve connections with gaskets

Lightweight and quick to install

High chemical and abrasion resistance

Inert to stray currents

Recyclable

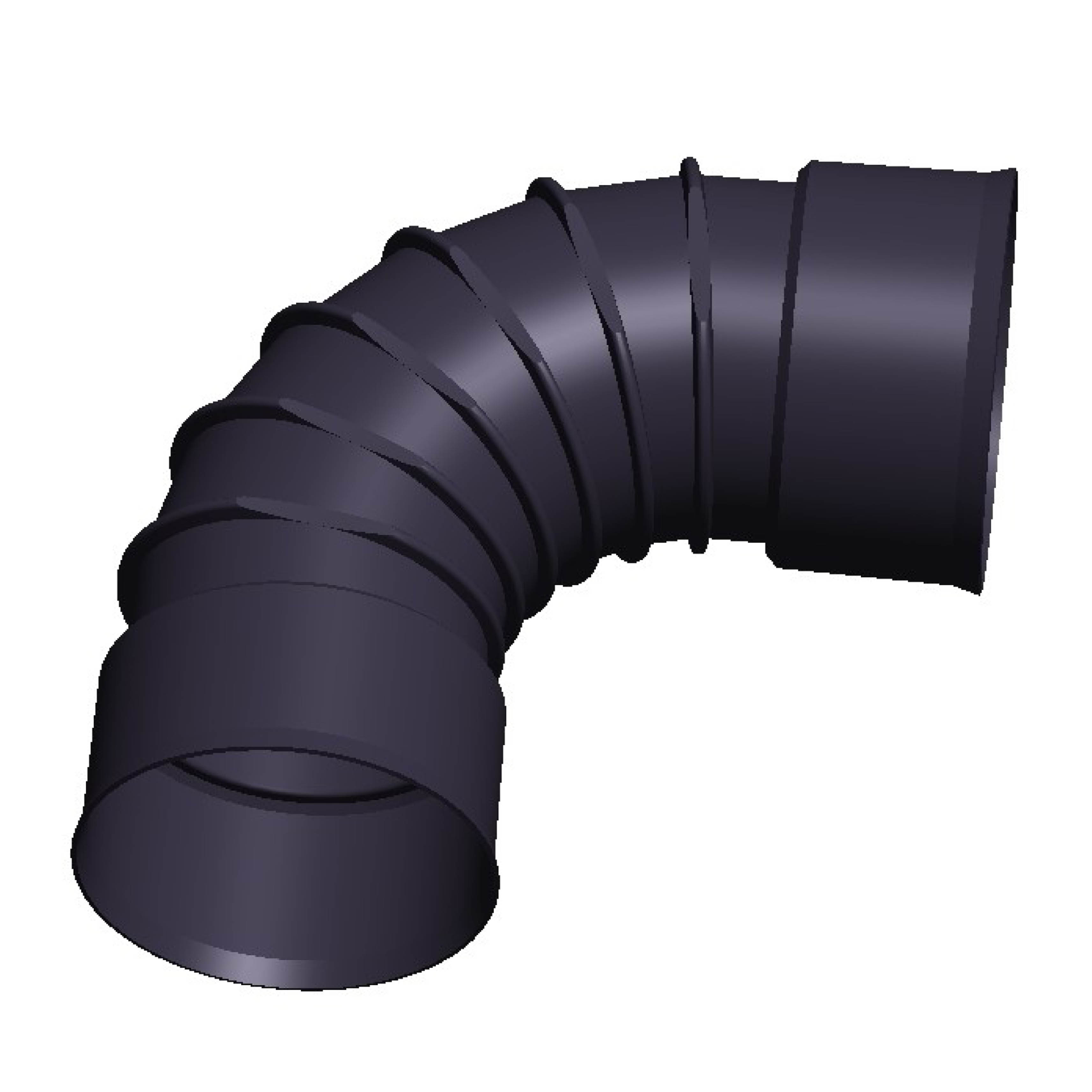

PE female/female formed fittings for double wall corrugated pipes for Non-pressure networks

Admin-2@tubiNet2023-05-16T20:38:19+02:00INJECTION MOULDED FITTINGS FOR PE AND PP CORRUGATED PIPELINE

BRIEF DESCRIPTION

Moulded fittings made of polyethylene for corrugated pipes which find application in sewerage and drainage systems without pressure. They are available in black colour, in standard shapes and angles with both ends provided with joint socket.

MAIN FEATURES

Wide range of diameters and shapes

Provided with joint socket on both ends

Smooth inner and outer surface

Lightweight and quick installation

High chemical and abrasion resistance

Inert to stray currents

Recyclable

Elbow 45°

Ø

160 | 200 | 250 | 315 | 350 | 400 | 500 | 630

.

Elbow 90°

Ø

160 | 200 | 250 | 315 | 350 | 400 | 500 | 630

.

45° TEE

Ø

160 | 200 | 250 | 315 | 350 | 400 | 500 | 630

.

90° TEE

Ø

160 | 200 | 250 | 315 | 350 | 400 | 500 | 630 | 701 | 800 | 935 | 1000 | 1200

45° elbow bend produced, up to DE 315 by injection molding in 100% HDPE and from DE 338 by rotational molding in 100% LLDPE , supplied by a UNI EN ISO 9001/2000 certified company.

90° elbow bend produced, up to DE 315 by injection molding in 100% HDPE and from DE 338 by rotational molding in 100% LLDPE , supplied by a UNI EN ISO 9001/2000 certified company.

90° TEE produced by injection molding in 100% HDPE, supplied by a UNI EN ISO 9001/2000 certified company.

.

.

90° TEE bend produced by rotational molding in 100% LLDPE , supplied by a UNI EN ISO 9001/2000 certified company.

.

.

Reducing M/F

Ø

da 160 a 200

da 125 a 160

.

.

Gasket

Ø

125 | 160 | 200 | 250 | 284 | 315 | 350 | 400 | 468 | 500 | 565 | 630 | 701 | 800 | 935 | 1000 | 1200

Coupler

Ø

125 | 160 | 200 | 250 | 315 | 338 | 400 | 452 | 500 | 630 | 701 | 800 | 935 | 1000 | 1200

Reducer produced by rotational molding in 100% LLDPE, in compliance with norm EN 13476-2, supplied by a UNI EN ISO 9001/2000 certified company.

COUPLERS DE …. pruduct by … (see tab. on reverse page) with dimensions in compliance with norm UNI EN 12201-3.

.

.

Segmented fittings for solid wall HDPE pipes

Admin-2@tubiNet2022-06-17T10:29:43+02:00Segmented fittings for solid wall HDPE pipes

BRIEF DESCRIPTION

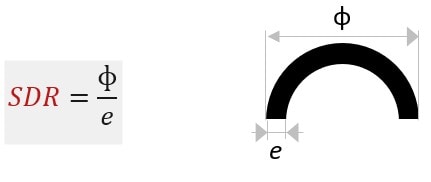

Fittings and special pieces consisting of sectors of high density polyethylene pipes with solid and smooth wall. They are available in black colour (with or without external coextruded coloured bands), in 2 layers (black on the inside and coloured on the outside) or coloured on the inside. The diameters range goes from 20 up to 1200 mm and of every kind of SDR.

MAIN FEATURES

Good drainage capacity

Pre-installed external filter sock

Cost-effective installation

Lightweight

Wide range of diameters

Inert to stray currents

High chemical resistance (ISO /TR 10358)

High abrasion resistance

High shock absorption resistance

Recyclable

CERTIFICATES:

FUTURA

Blueseal16 – Polypropylene compression fittings

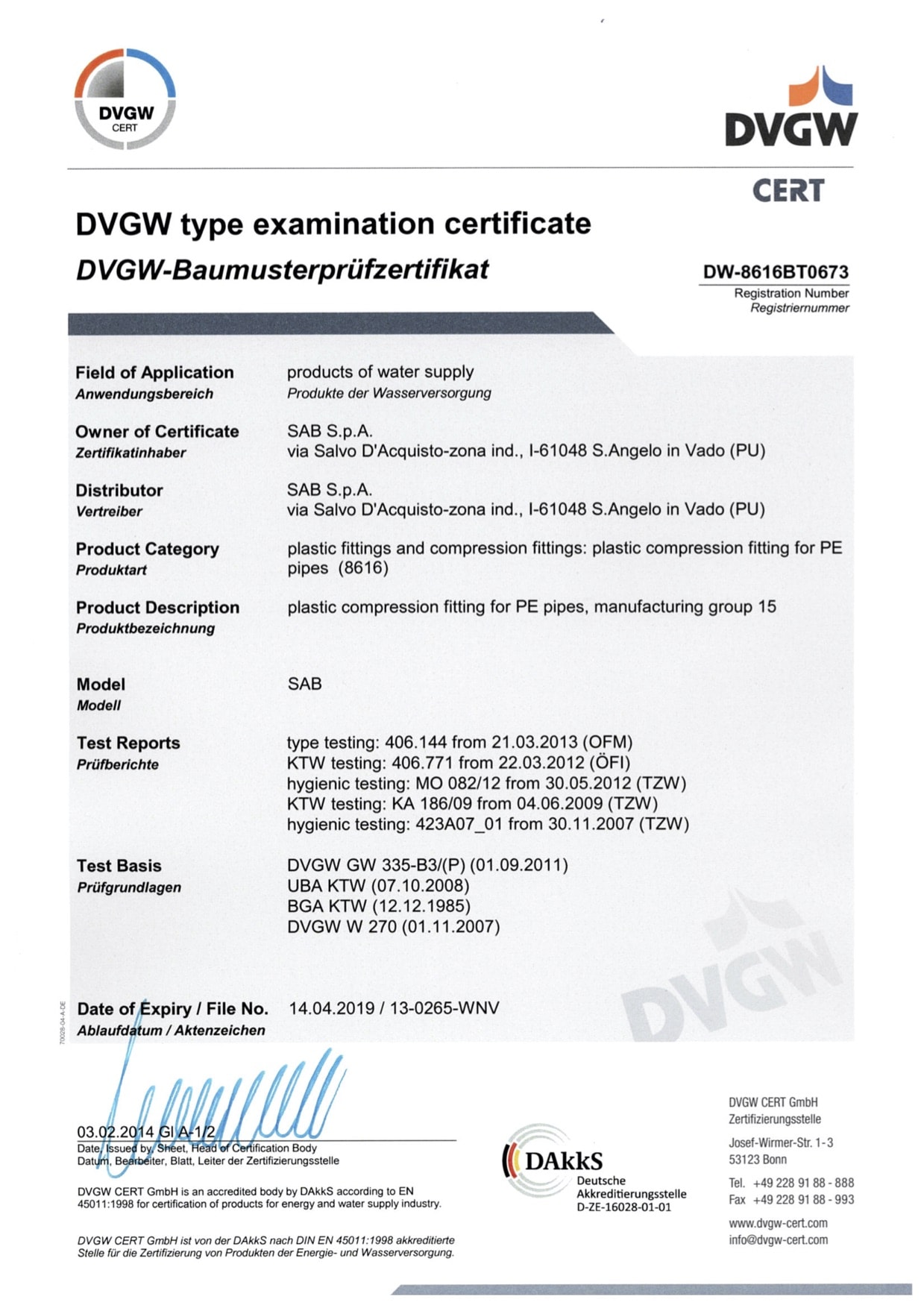

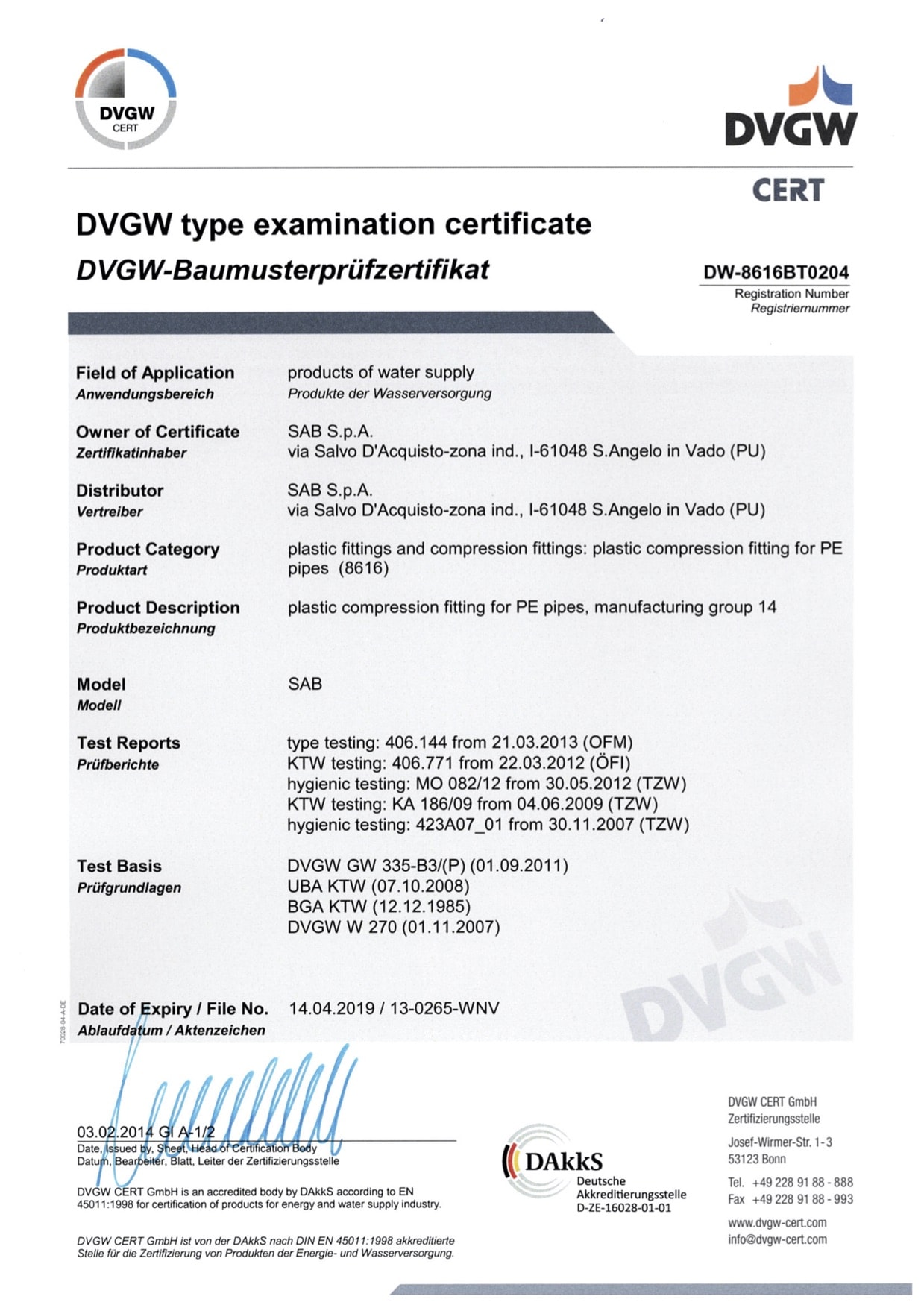

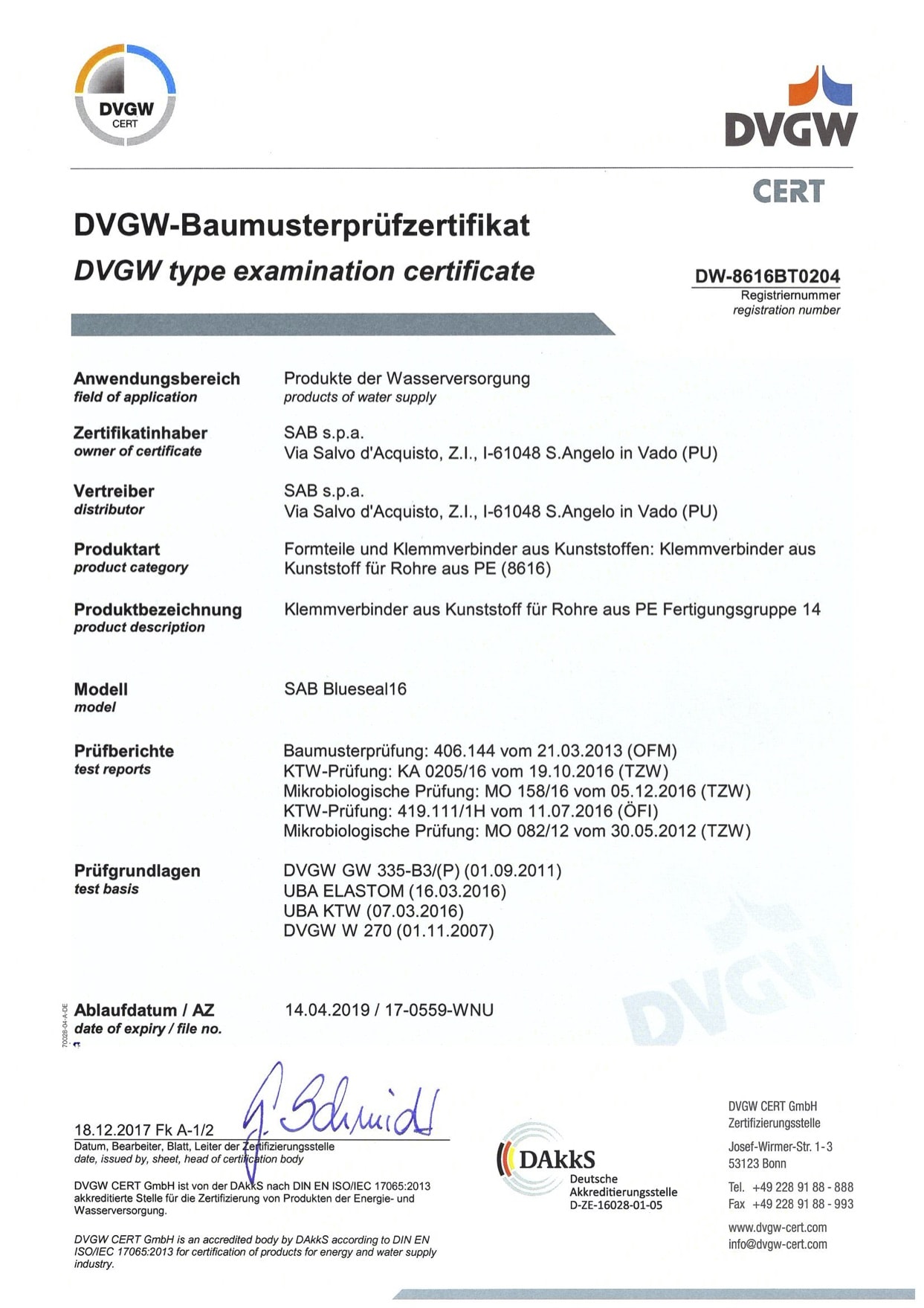

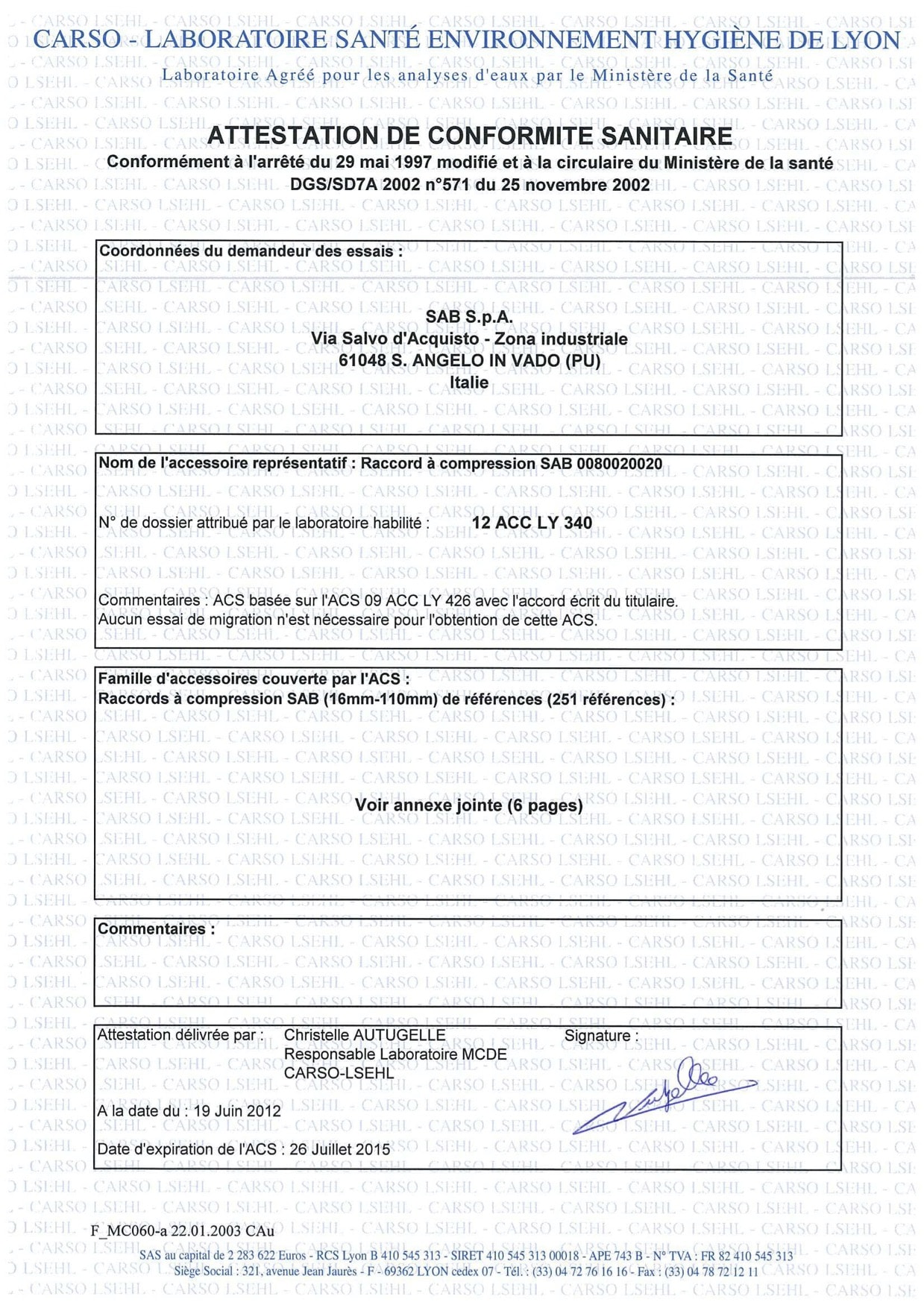

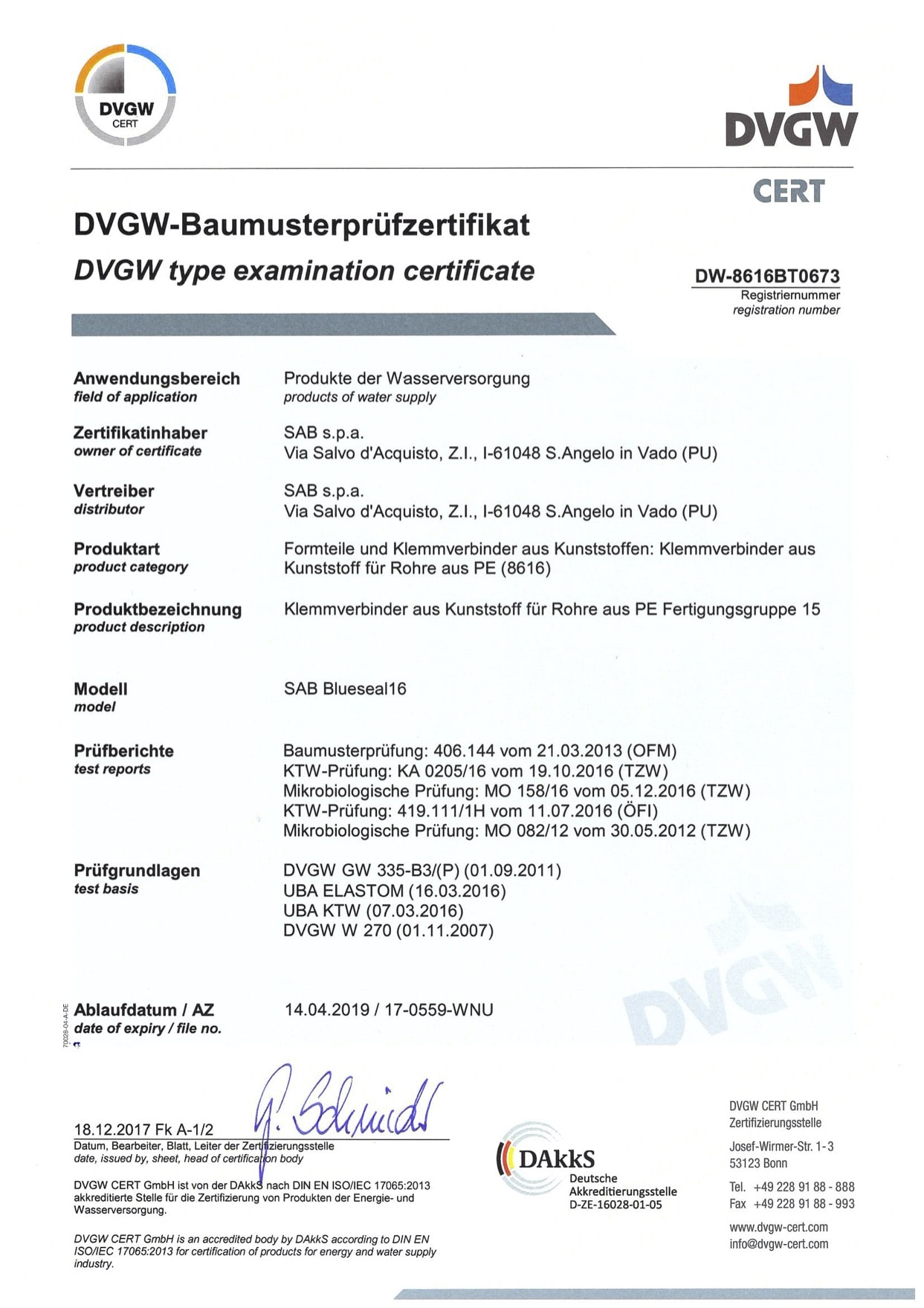

Admin-2@tubiNet2023-01-25T08:58:02+01:00COMPRESSION FITTING BLUESEAL

Compression fittings made of polypropylene (PP) for connecting polyethylene (PE) pipes that find application in drinking water pipelines PN16. Fittings are provided with lip seal and anti-slipping crimping rings and the diameters range (DN) goes from 16 to 110 mm. The complete range of compression fittings consists of more than 300 items, including couplings, elbows, Tee pieces (90° C), caps and reductions. Among the various types there are also PE-copper transition fittings, PE-metal universal fittings, fittings with threaded inserts made of brass and finally, fittings with Viton gasket and PBT crimping ring for usage in presence of acids. When the water pipeline is subjected to pressure, the patented tightness system allows to push the gasket against the pipe wall thanks to the “slide-effect” which increase the tightness level. Blueseal is also available with the O-ring gasket and in blue or black colour.

MAIN FEATURES

High water tightness reliability

Ease and quick installation

Better tightness

Wide range of fittings

High shock absorption ability

Recyclable

PE STEEL transition fittings

Admin-2@tubiNet2021-07-22T14:49:33+02:00PE STEEL transition fittings

BRIEF DESCRIPTION

PE-STEEL transition fittings, consisting of a SDR11 polyethylene sleeve (PE100) in accordance with UNI EN 1555 (for gas) or UNI EN 12201 (for water) standards which is suitable for the connection with PE 100 pipes (S5 for gas – PN16 for water) + a steel sleeve made of pipes in accordance with UNI 8863 standard, galvanised on the inside and with male threaded end or suitable for the welding connection. These fittings are used for underground fluids distribution systems (usually PE) which become above ground systems. These last ones are preferred to be made of steel for the advanced mechanical characteristics of impact resistance (accidents or acts of vandalism). The range of shapes includes: straight or elbow (45°- 90°). Transition fittings of PE-BRASS are available too.

MAIN FEATURES

Safety

Wide range of professional choices

Lightness

Practicality

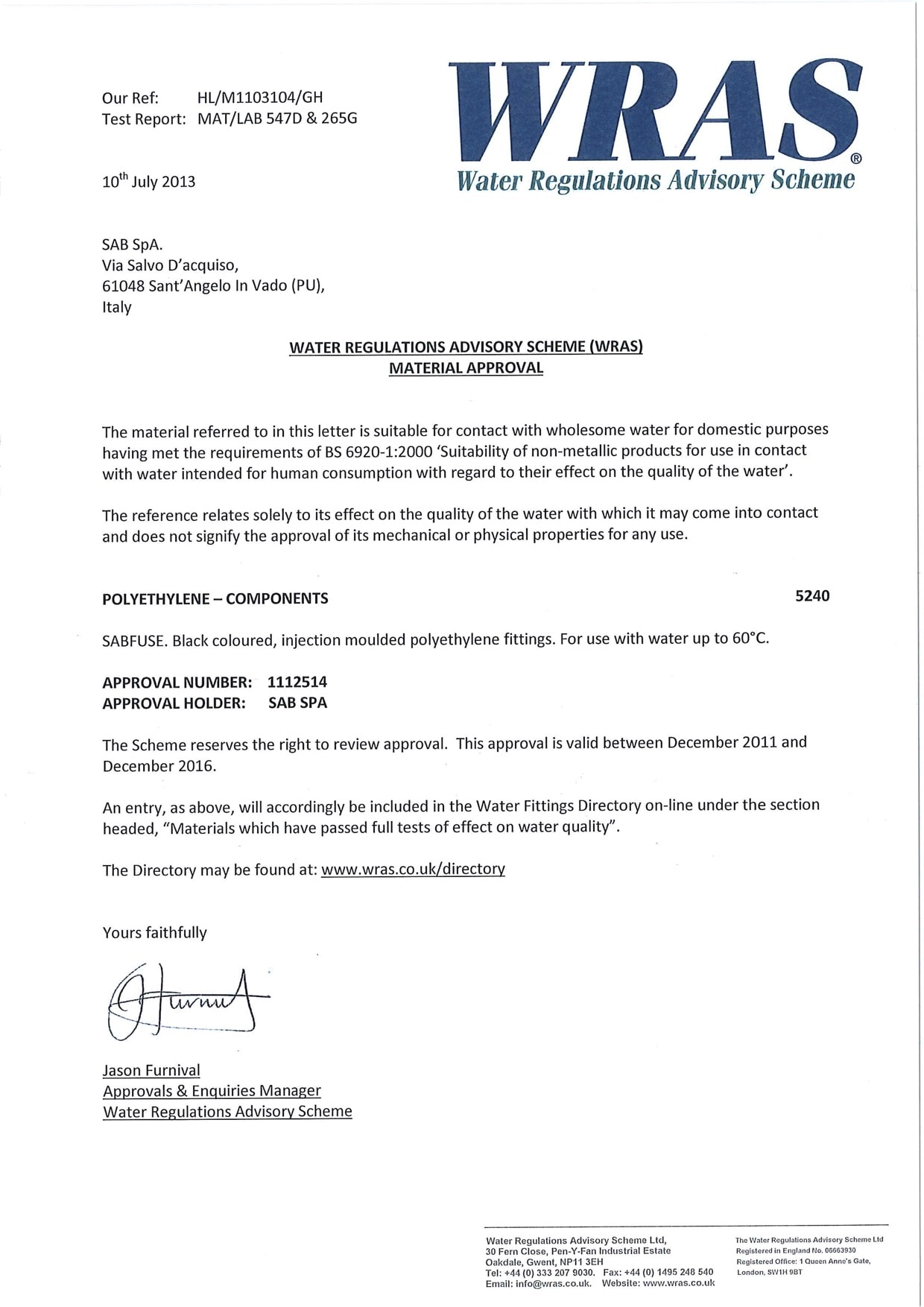

Electrofusion fittings Sabfuse

Admin-2@tubiNet2022-08-10T10:53:13+02:00Electrofusion fittings Sabfuse

BRIEF DESCRIPTION

PE100 Electrofusion fittings for connecting elements of polyethylene pipes (coils, bars, folders with flanges, special pieces) with pressurized and non-pressurized pipelines for the distribution of gas and water (for human consumption too). The electrofusion fittings have an inner metallic thread that, thanks to the passage of electricity, generates the heat requested for the fusion of the polyethylene in the inner surface of the fitting and the outer surface of the pipe, thus allowing the welding between the two elements. This operation takes place through welding machines, powered by specific generators connected to the fitting through cables inside the specific pins. There are also the “fusion witnesses” which are useful for the visual inspection of the properly fusion. The installation instructions can be read automatically by the device trough the barcode reported on every single fitting. Wide range of shapes (sleeves, bends, derivations, TEE pieces etc..) and diameters to work at nominal pressures of 6, 10, 16 and 25 bars.

MAIN FEATURES

Complete system

High tightness reliability

Fusion on the outer surface of the pipe (the inner welding seam is not created)

Suitable for pressurized and non-pressurized systems, up to 25 bar

Injected moulded fittings for solid wall HDPE pipes

Admin-2@tubiNet2022-06-20T18:11:05+02:00Injected moulded fittings for solid wall HDPE pipes

BRIEF DESCRIPTION

Injected HDPE moulded pieces for high density polyethylene pipes, with a smooth inner surface. The pieces are available in black colour and they can be connected trough butt-welding, with electrofusion fittings or mechanical fittings. SDR 17-11-7,4 range. They are used for the construction of systems for the fluids transport up to 25 bar pressure.

MAIN FEATURES

Wide range of shapes and diameters

Reliability

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

Coupler For PE Pipe Plug&Play

Admin-2@tubiNet2021-07-20T17:29:59+02:00COUPLER FOR PE PIPE PLUG&PLAY

A new COUPLER for PE pipes up to SDR11 PN16 with a double lip seal and specially designed grip ring. Simple, quick, reliable, with Plug&Play® you avoid welding, no need for glues, no wrench tightening. Plug&Play® is ideal for repairs and city work sites or impervious areas.

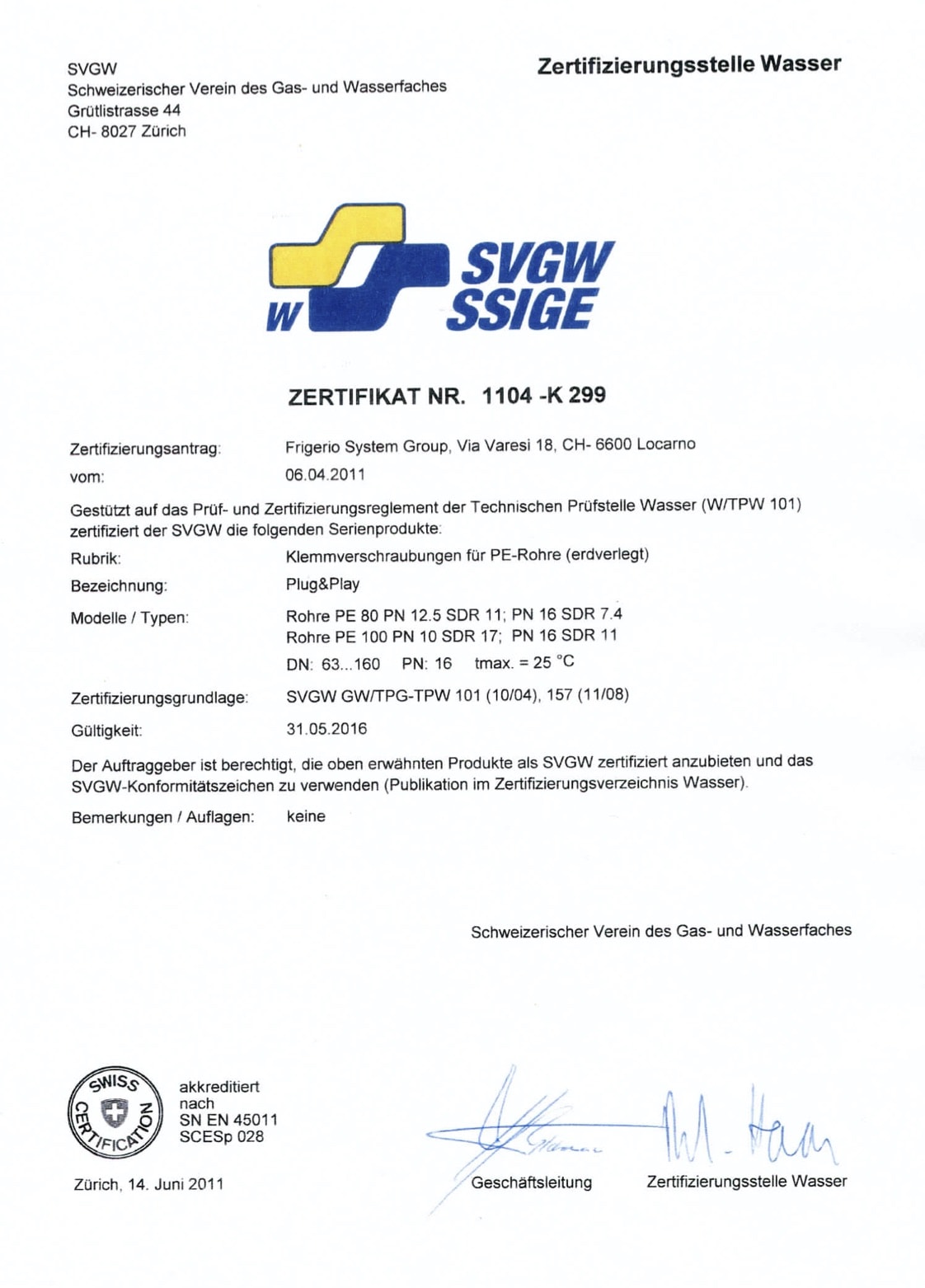

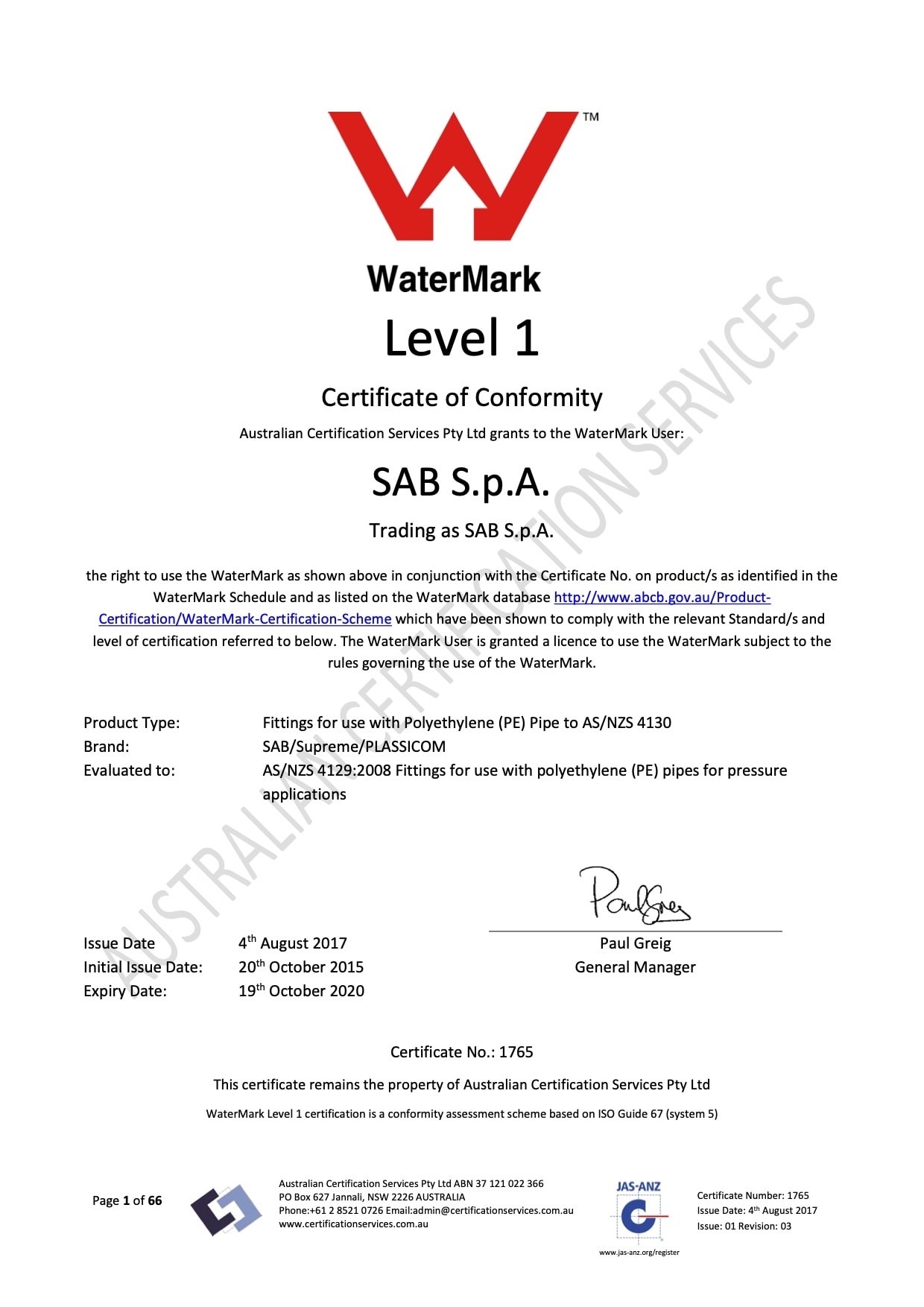

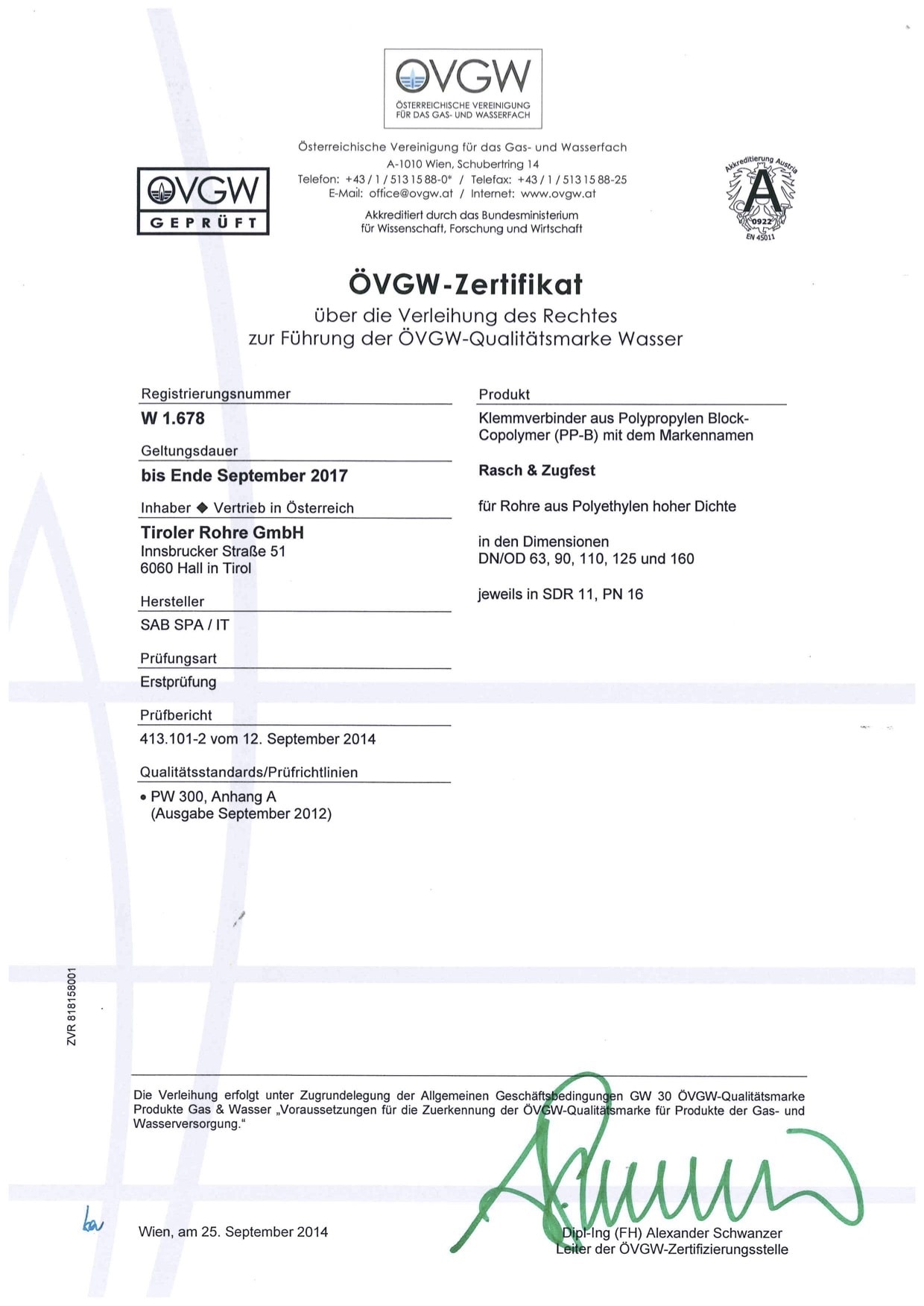

CERTIFICATES:

SABDRAIN – ROAD SURFACE PP DRAINAGE CHANNELS

Admin-2@tubiNet2023-04-12T15:46:00+02:00SABDRAIN – ROAD SURFACE PP DRAINAGE CHANNELS

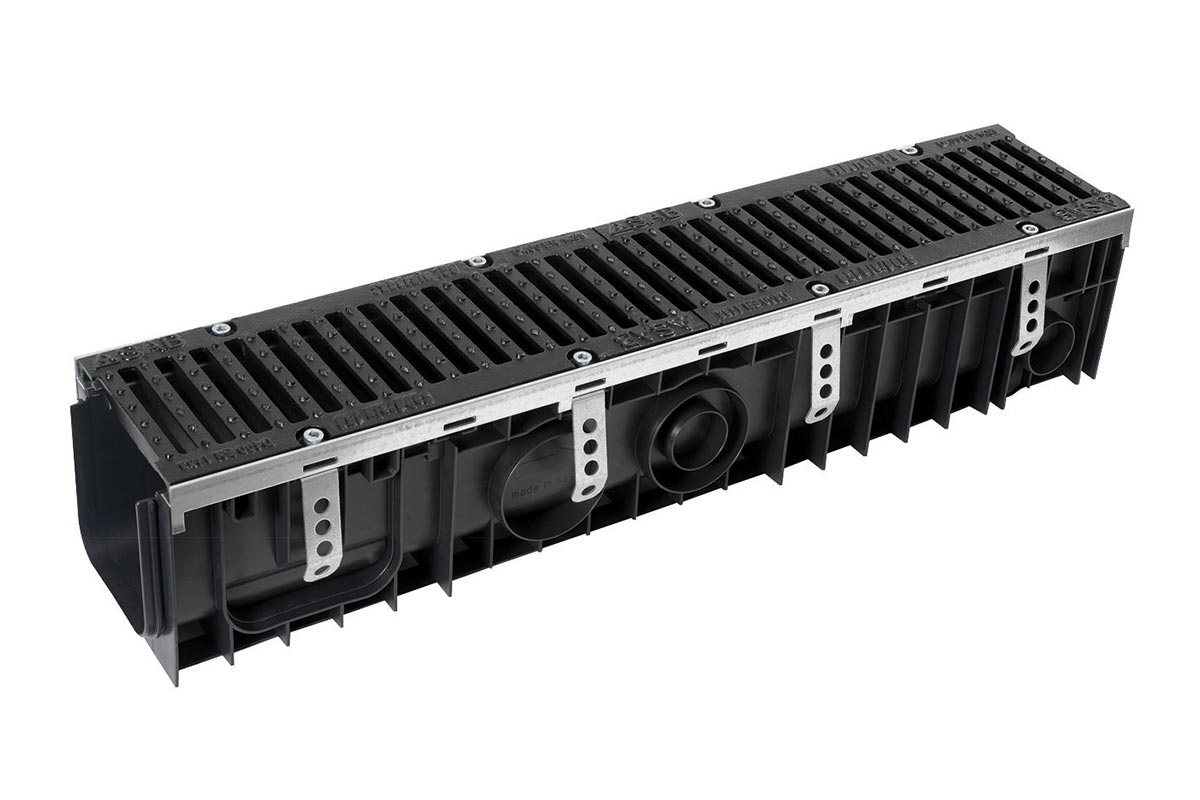

BRIEF DESCRIPTION

Drainage channels for road surfaces made of PP (polypropylene), provided with heel guard grids and made of various materials, suitable for all kind of load classes (from A15 pedestrians up to F900 airports). Channels are provided with:

- in line connection system of interlocking channels, available with a lateral inclination up to 2°

- predisposition to orthogonal connection system between channels

- predisposition to exit pipes connection, both sideways and on the floor

On demand:

- end-line caps

- baffles for channels connection with change in the amount of ground flow

Grids made of:

- PP (pedestrian)

- PAGF

- galvanised steel

- stainless steel

- cast iron

Suitable for:

- parking areas

- roads and highways

- service areas and fuel stations

- cycle and pedestrian path

- industrial areas

- ports

- airports

- chemical industries establishments

- slaughterhouses

- landfill sites

- Trails for vehicles entrance (mechanical workshops, garage etc.)

MAIN FEATURES

Application flexibility

Lightweight

Easy and quick to install

High chemical resistance

High abrasion resistance

High thermal shock resistance

Low roughness (excellent hydraulic behaviour)

Excellent mechanical resistance

CERTIFICATES:

SAB

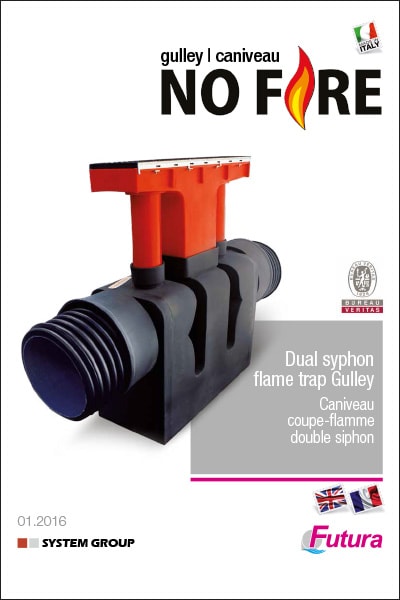

NO FIRE – Fire and environmental protection system in the tunnels

Admin-2@tubiNet2023-11-07T16:41:25+01:00NO FIRE – Fire and environmental protection system in the tunnels

BRIEF DESCRIPTION

NO FIRE is the system implemented in the collection of liquids that could be found on the road surfaces of tunnels.

It has a dual purpose: protects the environment from accidental spilled liquids and reduces the potential fire spread through the manifold.

The system consists of several units: NO FIRE storm drains made of two siphons (with a drain grid D400 load class) + standard PP corrugated pipes (other can be used on request) + water treatment system.

The NO FIRE system was designed and developed to satisfy all safety standards (in terms of personal and environment) requested by recent road tunnels, the planned ones and the ones that will be upgraded.

MAIN FEATURES & BENEFITS

Safe and tested system;

In conformity with the security standards requested by TERN networks;

Multiple sizes available, for pipes with DN/OD 250-315-400 mm and DN/OD 300-400 mm;

Gravity system (no electromechanical devices);

Environmental safety in case of fire (no fire and smokes spread in the manifold);

Surface drainage channel: 500 x 270 mm;

Lightweight and ease of installation;

Durability: a cement mortar coating guarantees the functioning of the system in case of fire too;

High chemical and abrasion resistance;

Inert to stray currents;

Excellent benefit-cost ratio;

Full technical support by the U. T. System Group.

CERTIFICATES:

FUTURA

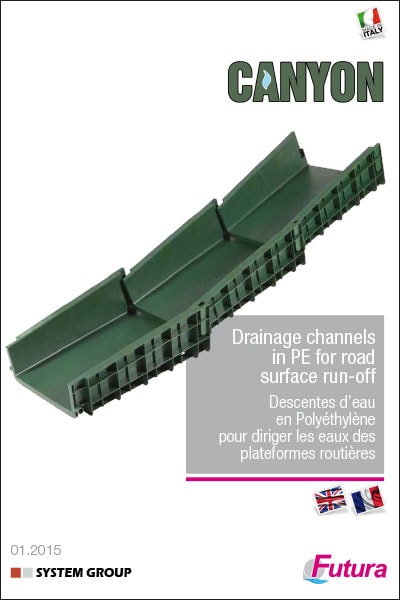

CANYON – PE DRAINAGE CHANNELS FOR ROADS AND RAILWAYS RUN-OFF

Admin-2@tubiNet2023-03-29T11:41:18+02:00EMBRICE IN PE CANYON PER SCARPATE STRADALI

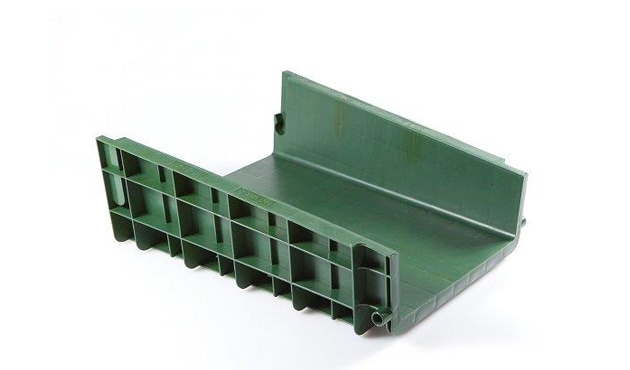

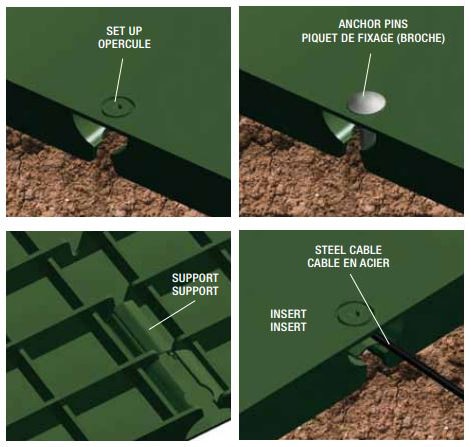

BRIEF DESCRIPTION

Polyethylene (PE) plain roofing tiles for liquids conveyance on high slope surfaces, such as roads and railways with embankments or landfill sites. They are available in green colour, provided with reinforcement lamellas on the outer surfaces which are useful for the improvement of the fixing in the laying ground; with double cylindrical pin connection that allows the height variation ± 20° and the thermal expansions absorption; with the predisposition to ground fixing through drift piling or steel cable.

MAIN FEATURES

Lightweight

Easy, fast and safe to handle and manual installation

Built-in interlocking connection system between the elements

High chemical and abrasion resistance

Recyclable

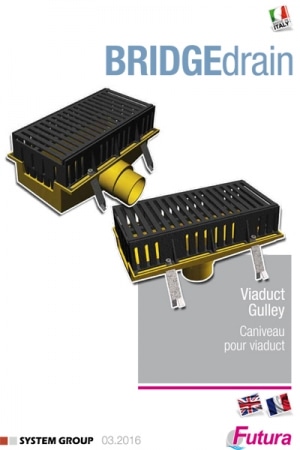

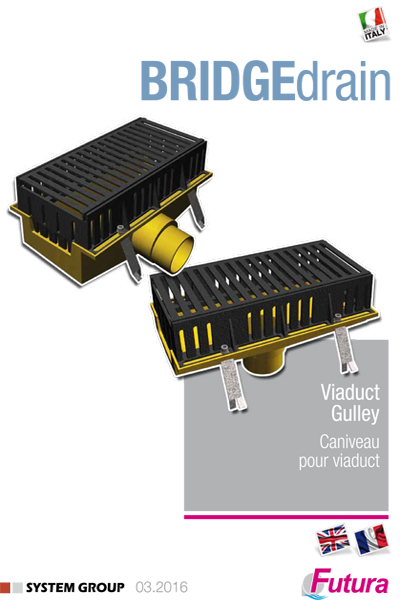

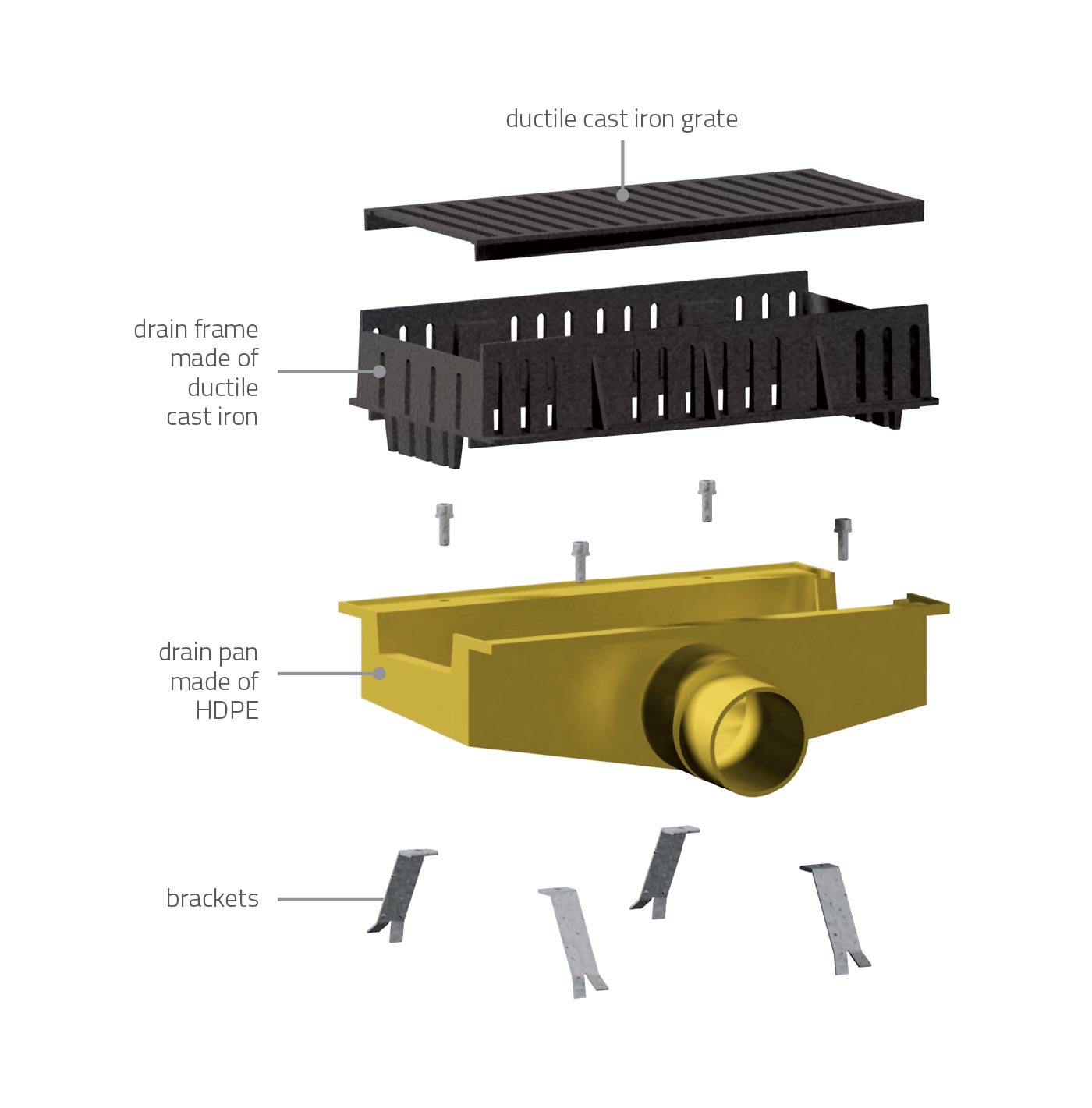

BRIDGEDRAIN – ROAD SURFACE DRAINING FOR BRIDGES AND VIADUCTS

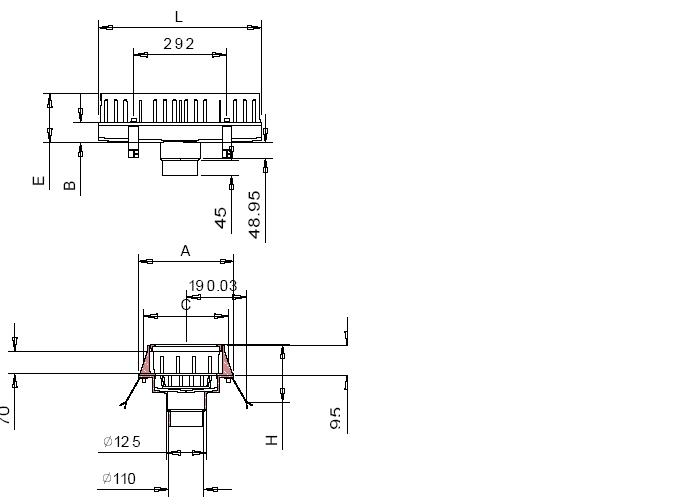

Admin-2@tubiNet2023-03-24T17:13:46+01:00BRIDGEDRAIN – ROAD SURFACE DRAINING FOR BRIDGES AND VIADUCTS

BRIEF DESCRIPTION

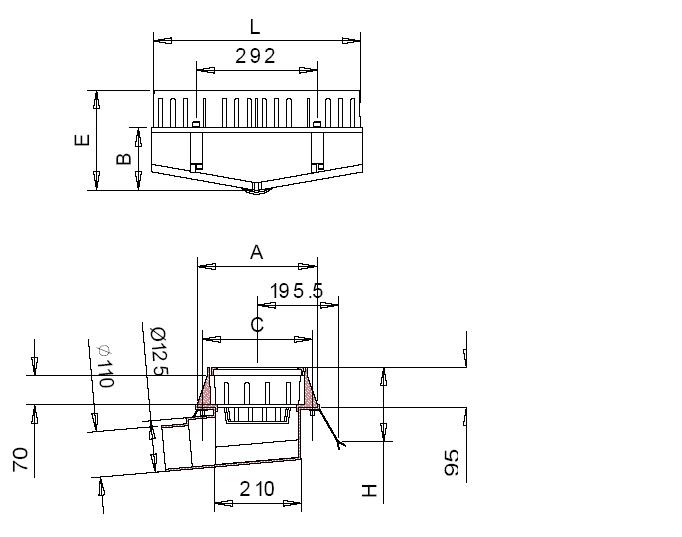

Storm drain for drainage of road surfaces made of draining asphalts on bridges and viaducts. It consists of a polyethylene drain pan with slots for pipes with OD of 110 and 125 mm (options: vertical or oblique outlet) + a cast iron drain frame and a grate of the same material of load class D400 + 4 brackets + fixing bolts.

MAIN FEATURES

Length: 500 mm

Width: 250 mm

Load class: D400

Drain pan made of HDPE

Slots drain for pipes with OD of 110 mm and 125 mm

The outlet direction can be vertical or oblique

Steel galvanised brackets

Cast iron drain frame

Cast iron grate

Geolocation and referencing system for underground networks – Pipe Tracer

Admin-2@tubiNet2024-07-04T08:49:23+02:00Geolocation and referencing system for underground networks – Pipe Tracer

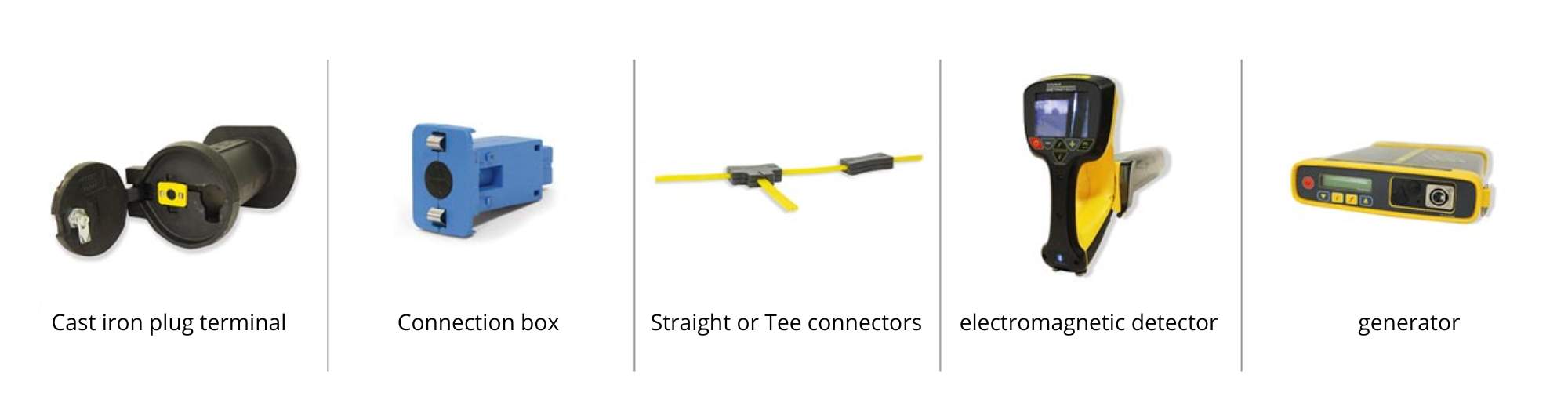

GENERAL DESCRIPTION

High-precision geolocation system + referencing of underground network infrastructures, to be positioned on the outer upper generatrix of the pipes during installation. The system is composed of:

- A small steel cable completely coated with polyethylene to be isolated and protected from the aggressiveness of the surrounding environment (soil pH, stray currents, water)

- Straight and TEE connectors for watertight connections between the cables

- Plastic connection boxes for the introduction of the electromagnetic signal, equipped with two stainless steel fins to allow grounding

- Connection jack to the connection box for the introduction of the electromagnetic signal

- Small cast iron terminal manholes to house the individual connection boxes when placed on pedestrian or vehicular pathways

- “WBH”* plastic frames, fixable to cement, plastic walls (manholes, valves and water meter boxes), or poles, for positioning and securing the connection boxes and grounding connection

- RFID (Radio Frequency Identification) tags – on request – for recording and reading of referencing information of individual network sections, placed inside the cast iron terminal manholes or on the WBH frame

The installed system remains passive throughout its lifetime but can be activated at any time by introducing an electromagnetic signal from any connection box via a specific generator (external portable). This condition makes the cable continuous sly traceable by appropriate instruments (available on the market in various brands and types) with a high degree of precision, obtaining 3D GPS coordinates. The RFID tags are writable and readable with specific instruments or simple smartphones equipped with NFC technology.

* WBH: Wall Box Holder

MAIN FEATURES

High degree of 3D localization accuracy

Creation of precise underground maps

Enhanced safety for construction workers

Reduced intervention times when necessary

Deterrent against negligent installation (exact detection of position and depth of buried pipes)

Durability (chemical and electrical inertia)

Suitable for any type of material, shape, and size of buried pipes

Electromagnetic signal suitable for any type of service (water, gas, energy, telephony, optical fibers, etc.)

Ease and speed of installation

Specialized watertight fittings

Referencing system for individual sections of pipelines

The Pipe Tracer geolocation system brings significant operational advantages to utilities, impacting moderately on the extra cost for project execution borne by the contractor. It represents an optimal trade-off between costs and benefits.

In this regard, companies SOLIMENO, BICICCHI, and CERAGIOLI have won important tenders in the TUSCANY REGION by proposing this innovative system for georeferencing underground pipelines to contracting authorities (GAIA and NUOVE ACQUE). Network managers also need to carry out fast and cost-effective interventions while minimizing disruption to the populations in affected areas (excavations on roads and/or sidewalks), thereby avoiding damage to other underground infrastructures and service interruptions.

With Pipe Tracer, there is effectively a perfectly traceable infrastructure mapped in terms of both plan and altitude (3D coordinates), with a high degree of precision, regardless of the type, diameter, and material of the pipes to be traced. This ensures the operators to avoid any damages to the existing buried networks.

References

TUSCANY REGION

[dicembre 4th, 2019|Products Focus, References]

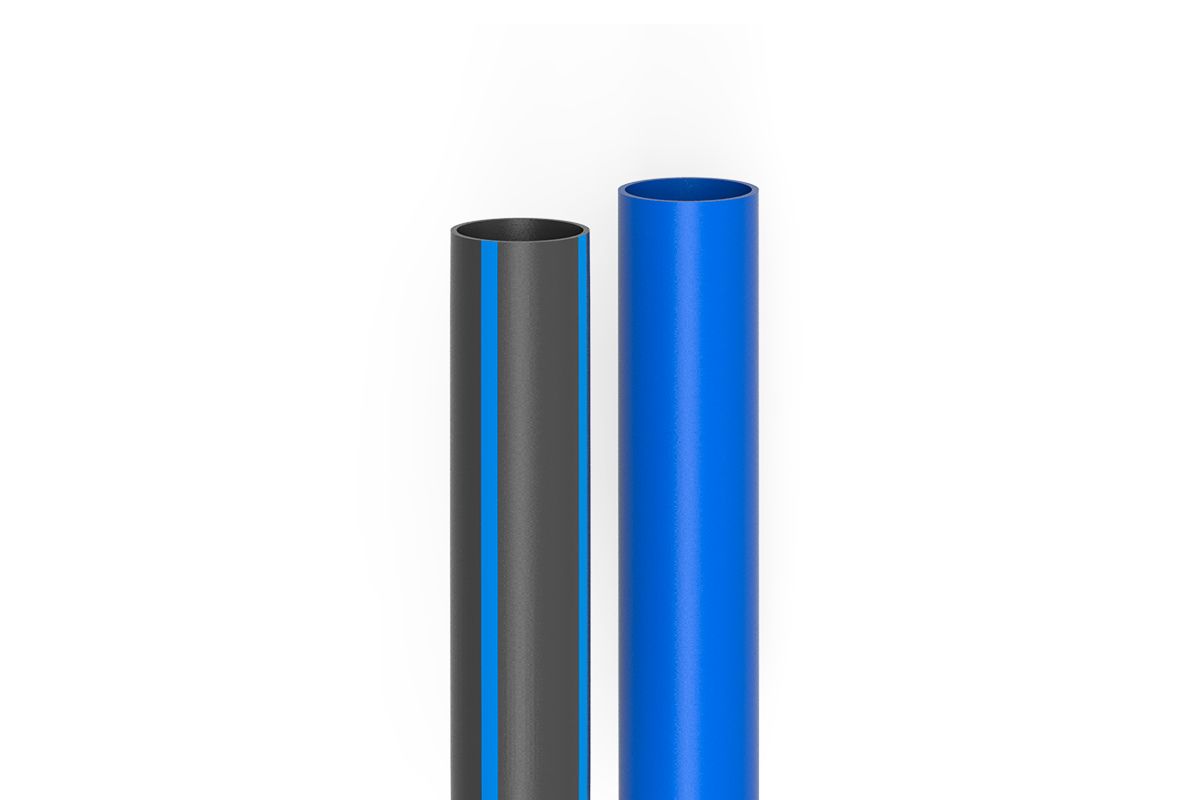

PE 80 pipe for pressurized water networks

Admin-2@tubiNet2021-07-22T11:09:46+02:00PE 80 pipe for pressurized water networks

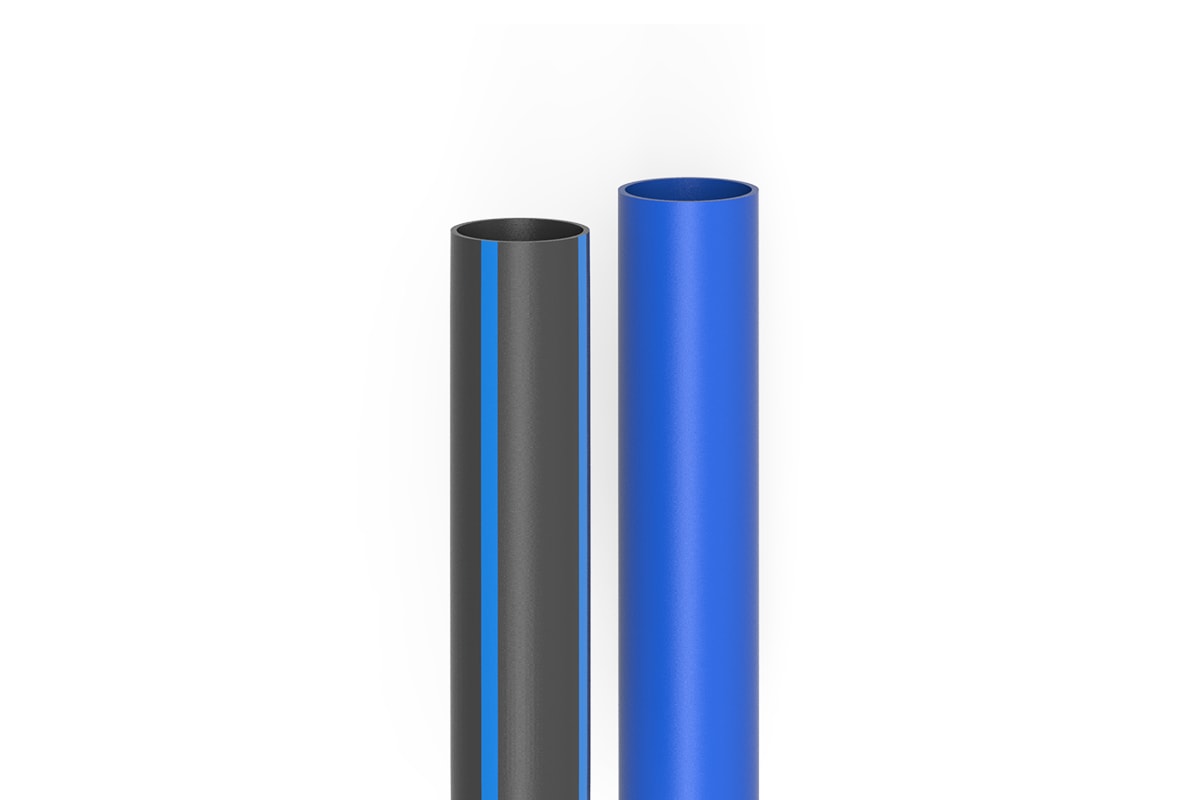

BRIEF DESCRIPTION

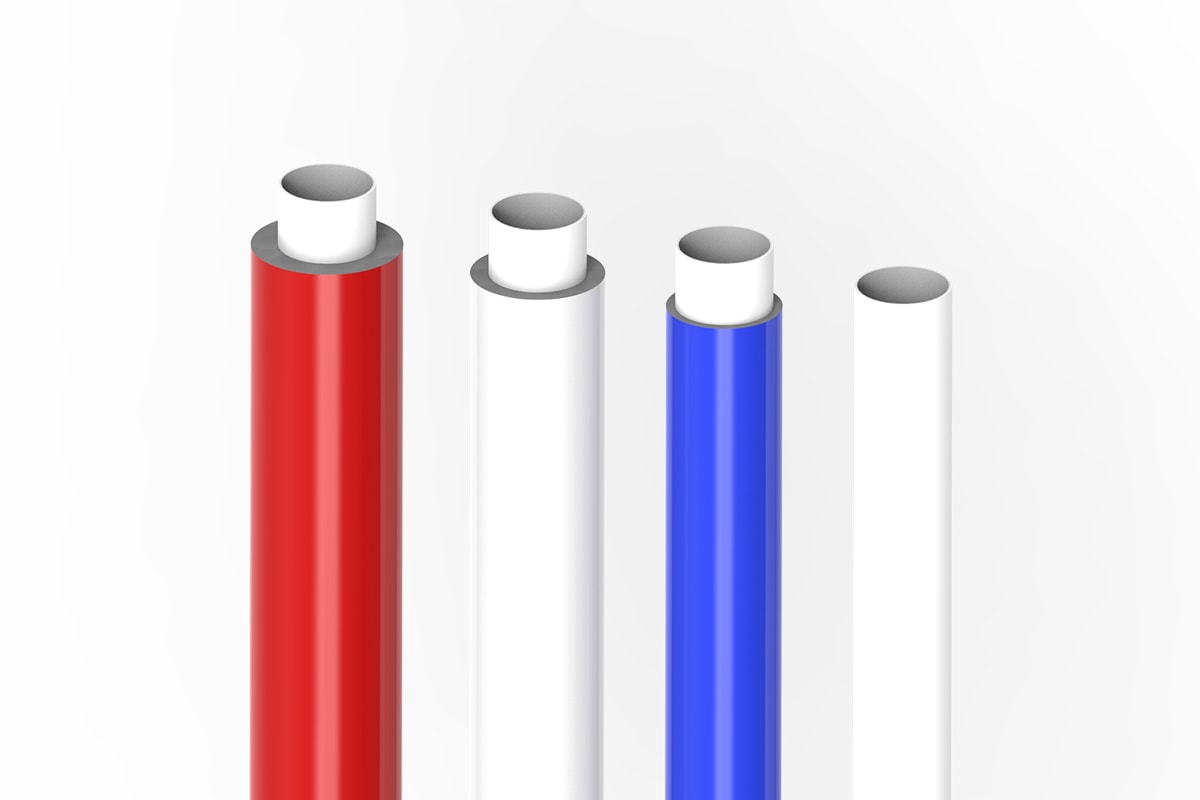

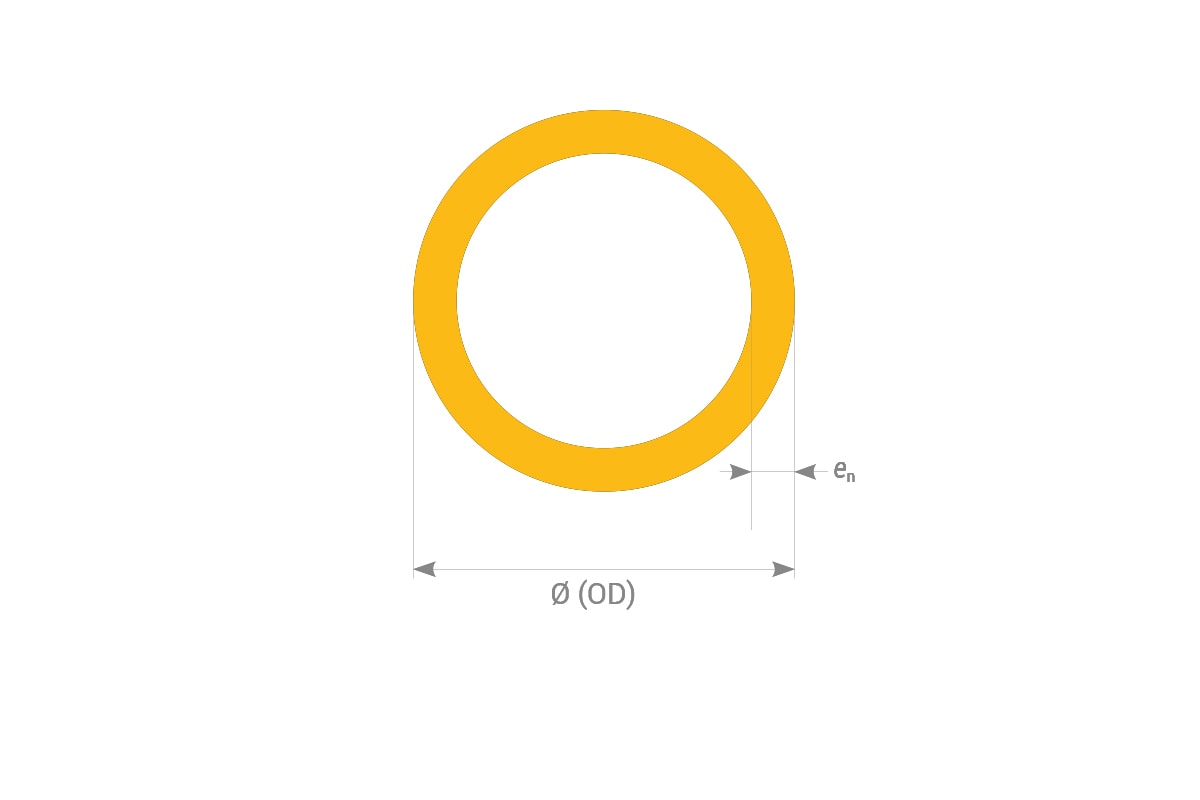

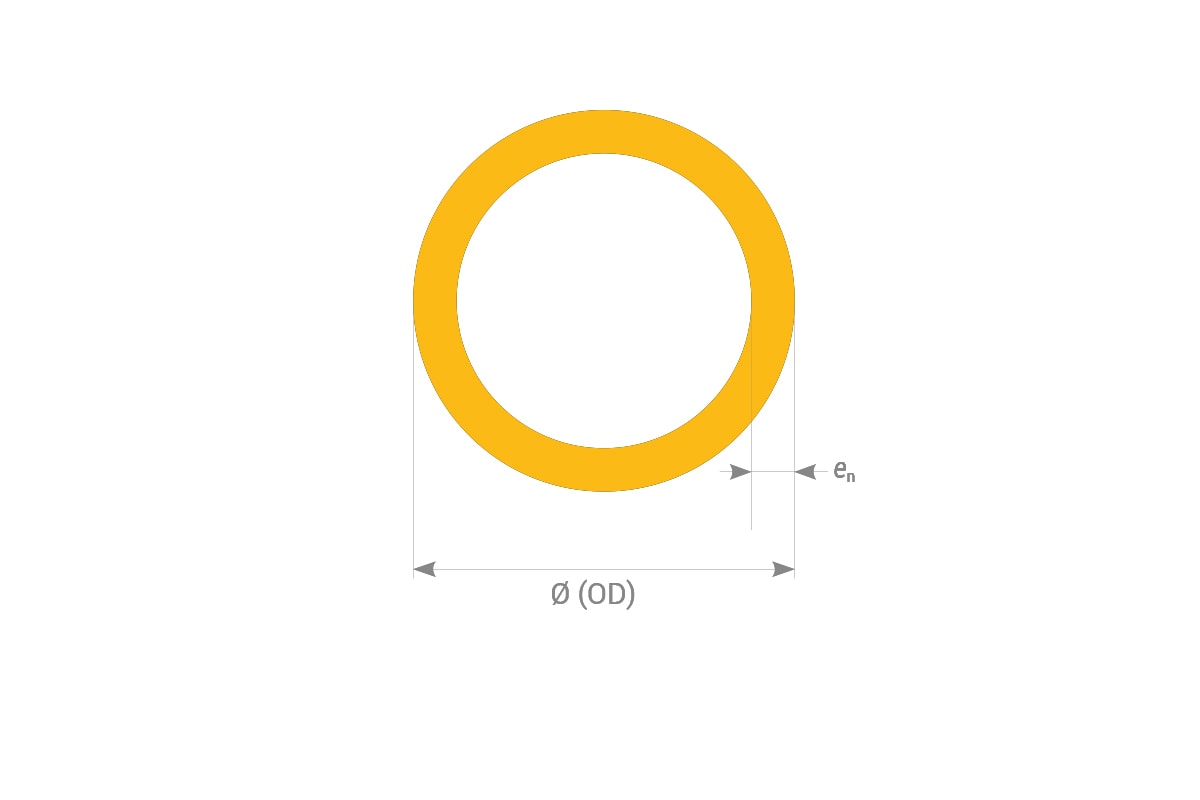

Solid wall pipes made of PE 80 (MRS 8 MPa – σS 6,3 MPa) with a smooth inner and outer surface, available in black colour (with or without external coextruded coloured stripes) or completely blue. Diameters (OD) go from 20 up to 1200 mm. Pipes can be delivered in coils and bars.

MAIN FEATURES

100% permanent water tightness

Good bending properties, particularly appreciated in manual applications in colder climate

Low modulus of elasticity

Plastic behavior in unstable circumstances

Wide range of diameters and pressure classes (sizing optimization)

Wide range of fittings and special pieces, standard and customized

Related to aqueducts, this pipe is in conformity with the EN 1622 standard about “determination of threshold of smell and taste”

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

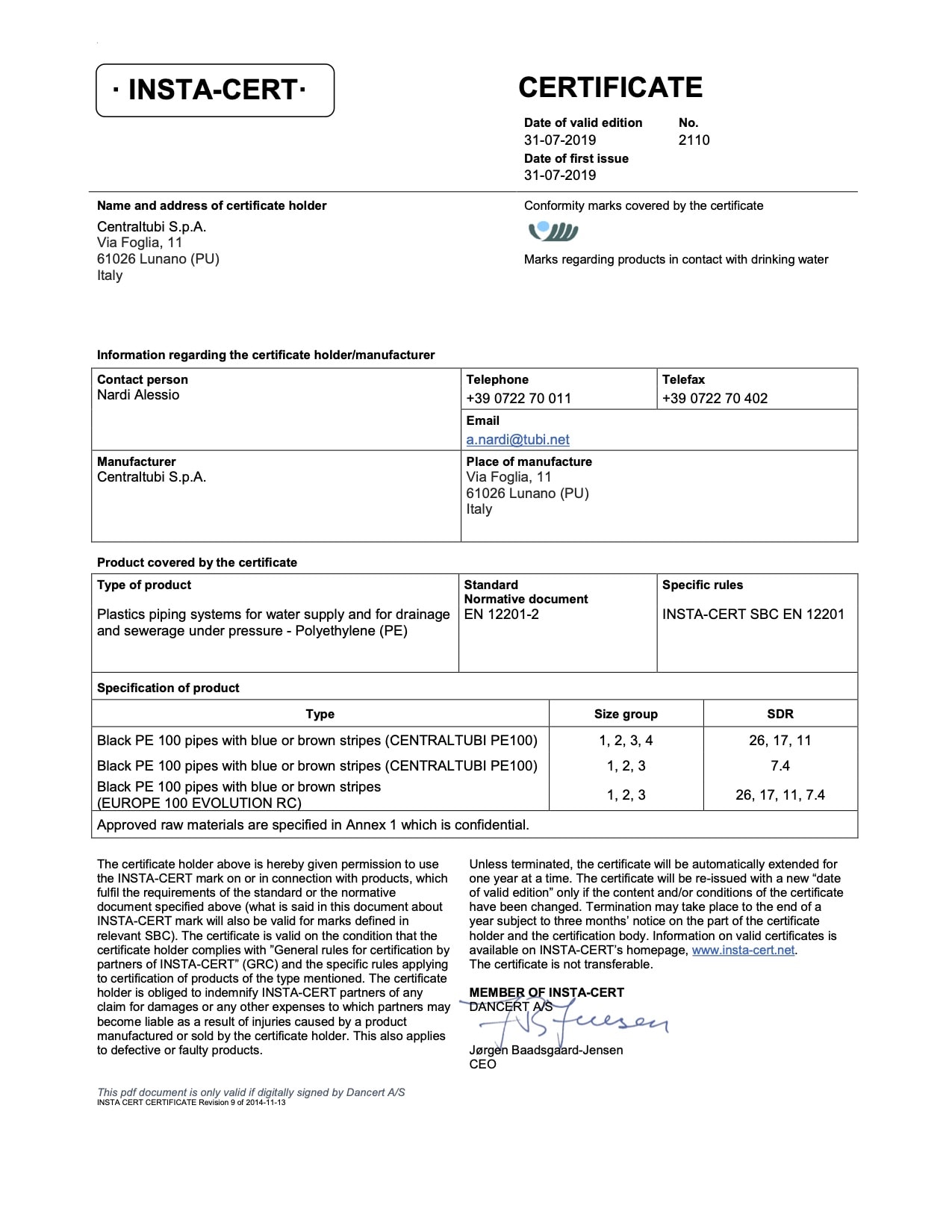

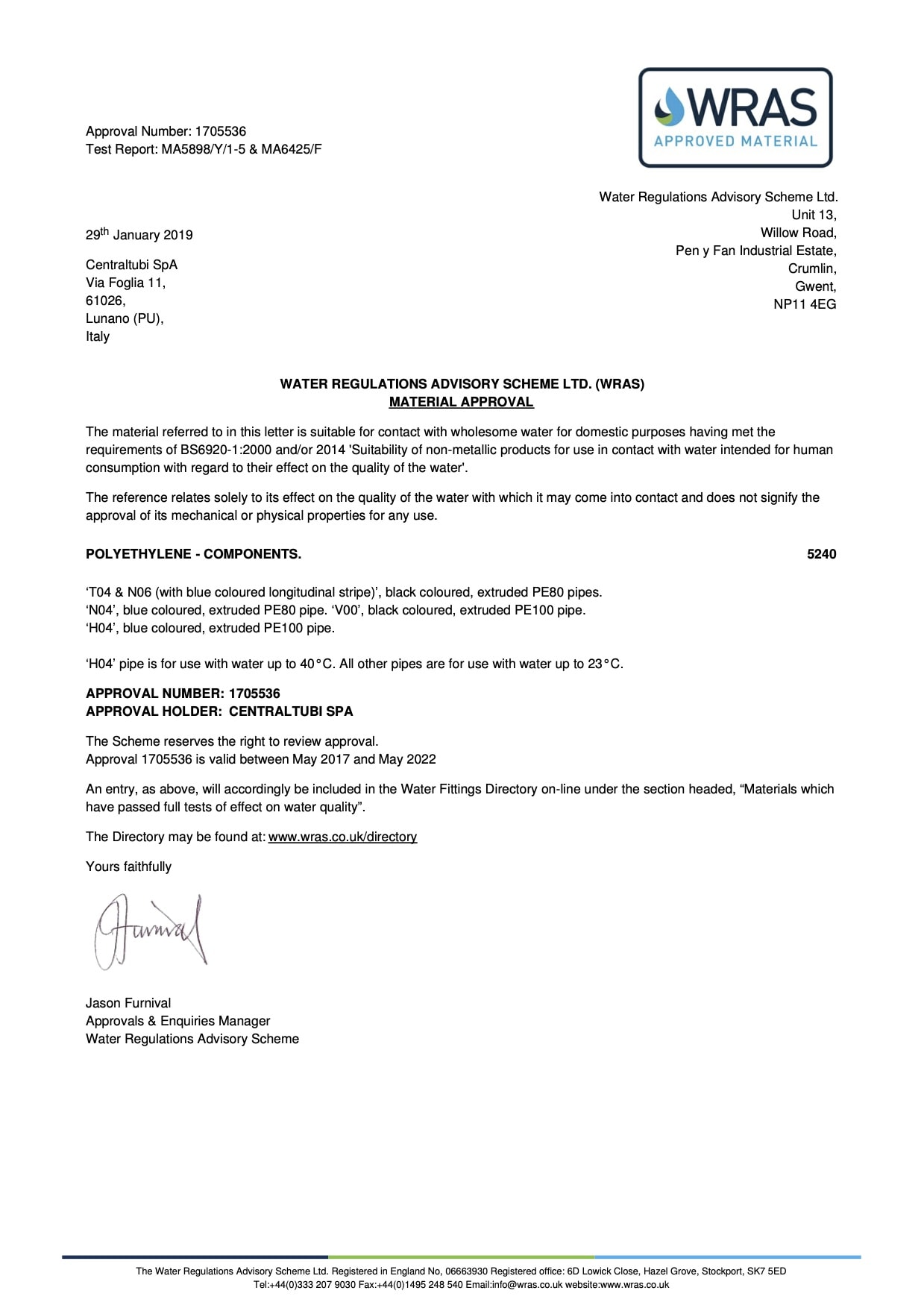

Solid wall PE 100 pipes for pressurized water networks

Admin-2@tubiNet2024-07-02T09:26:18+02:00Solid wall PE 100 pipes for pressurized water networks

BRIEF DESCRIPTION

Solid wall pipes made of PE 100 (MRS 10 MPa – σS 8 MPa) with a smooth inner and outer surface, available in black colour (with or without external coextruded coloured stripes) or completely blue.

Diameters (OD) go from 20 up to 1200 mm. Pipes can be delivered in coils or bars.

MAIN FEATURES

100% permanent and watertight seal

Pliability

Wide range of dimension and performance choice

Very high chemical, electrical and biological resistance

High abrasion resistance

Low elasticity modulus

Plastic behavior in unstable situations

Reduced number of joints

System Homogeneity

Lightness

More resistant to chemical agents compared to other materials

Security

Savings

Recyclable

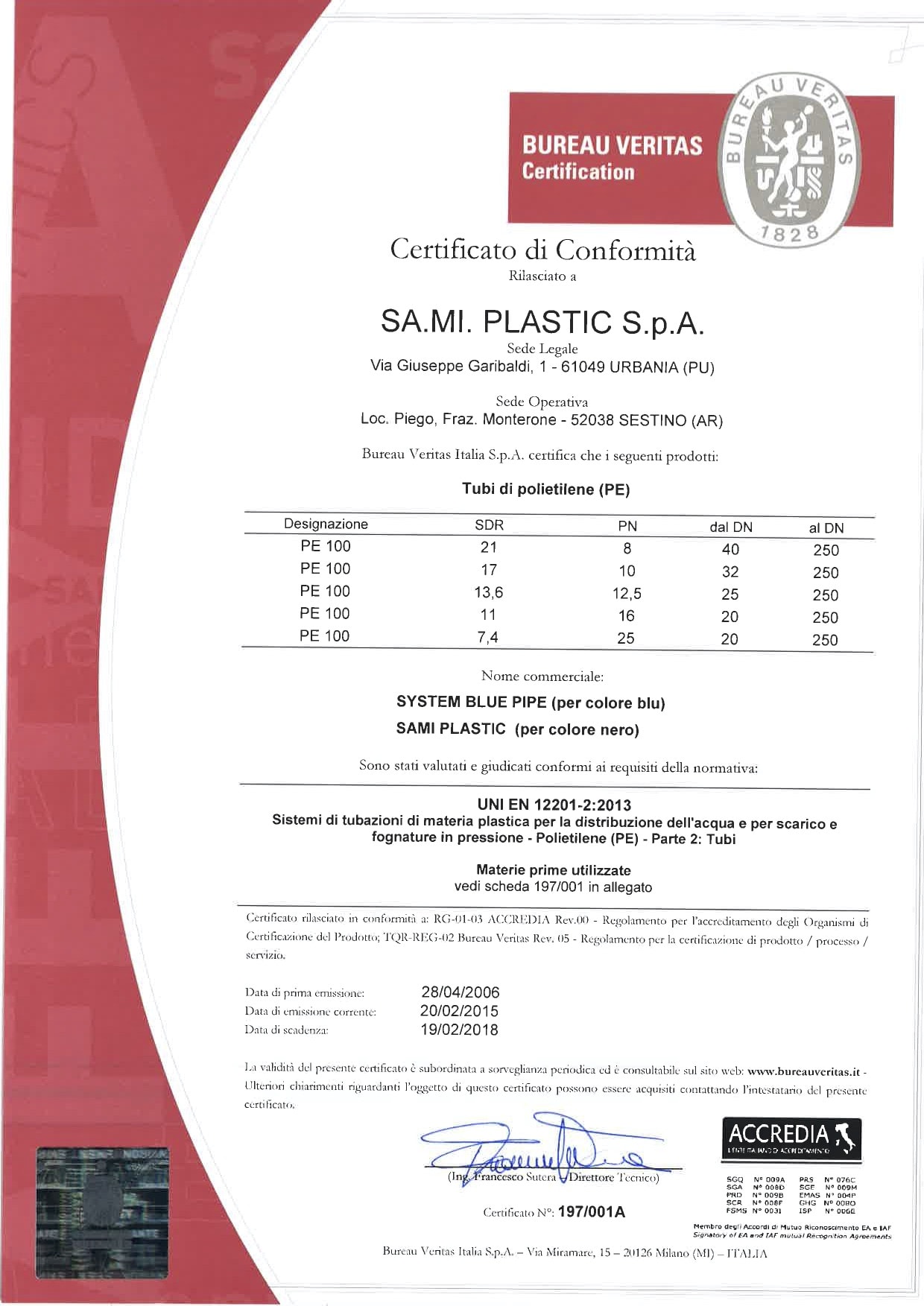

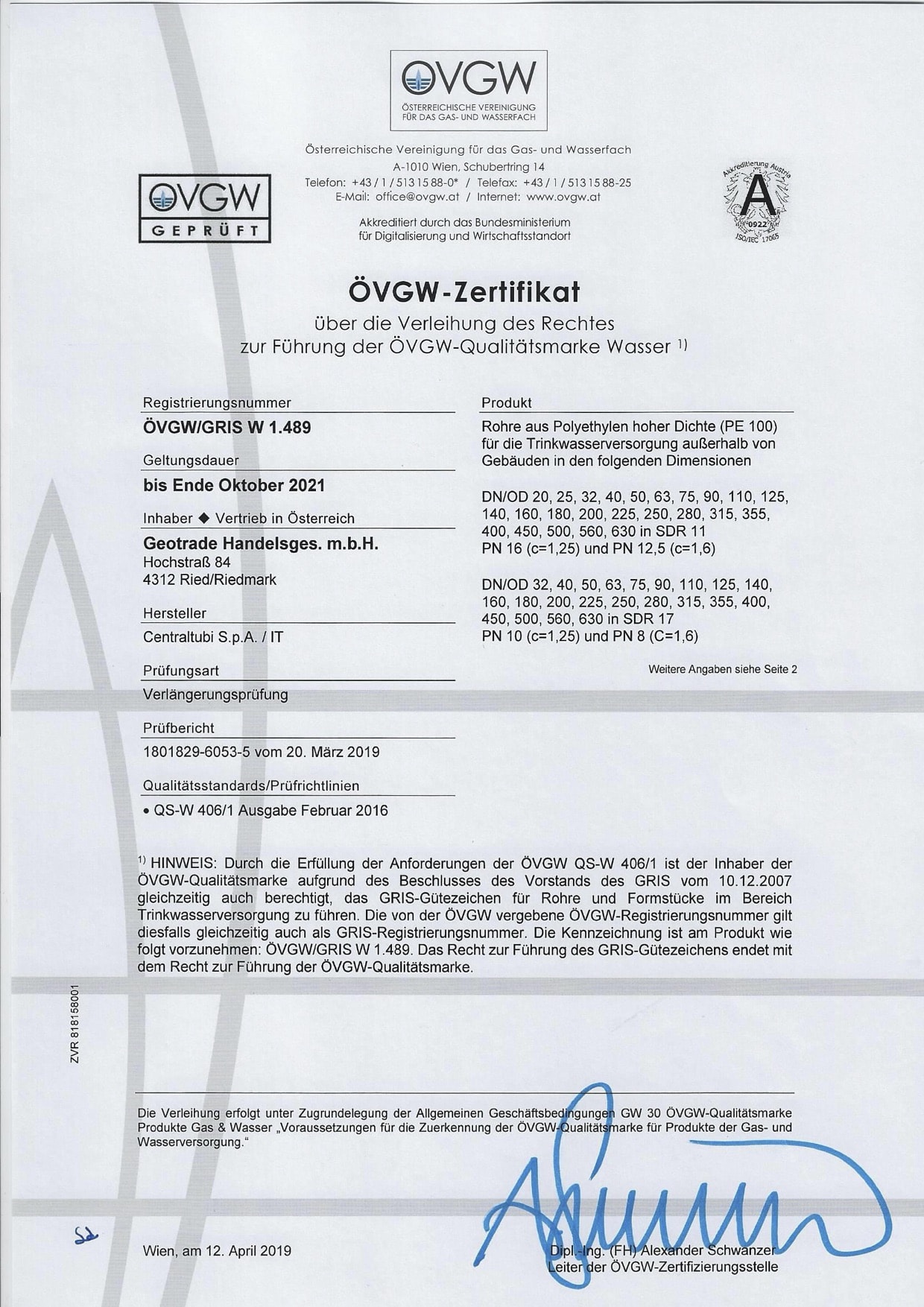

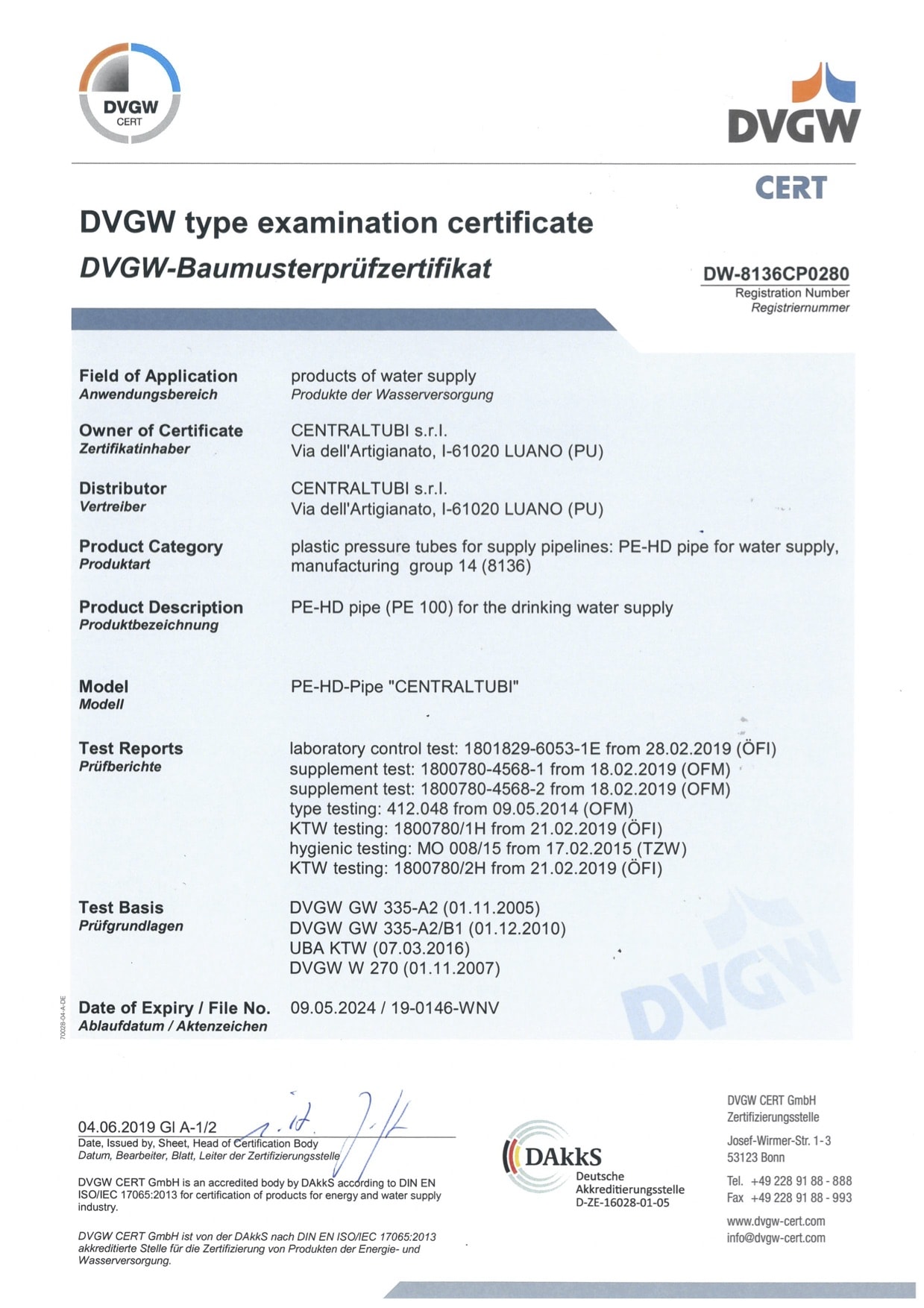

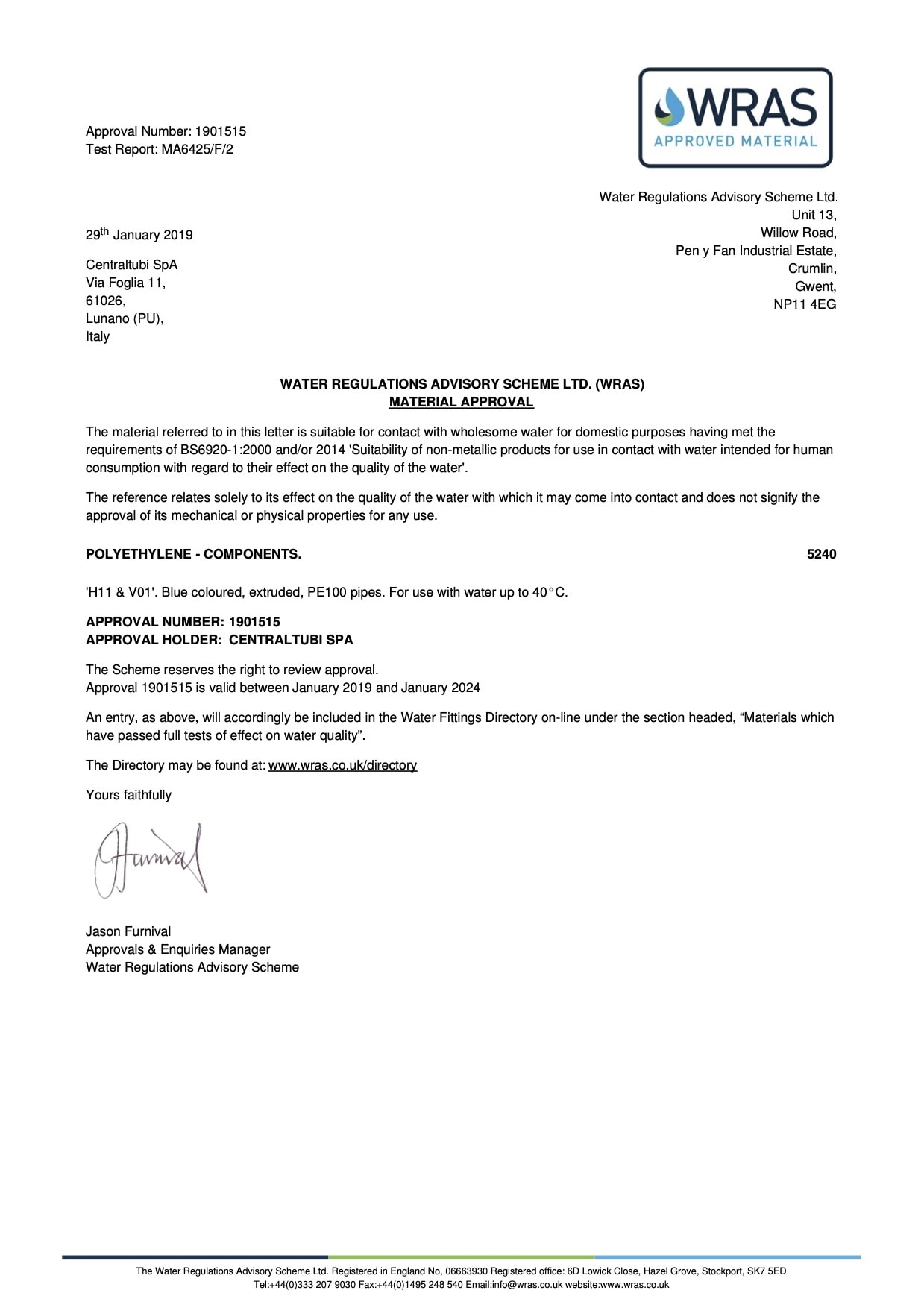

CERTIFICATES:

CENTRALTUBI

BureauVeritas UNI EN 12201 ACQUA

IIP PE100 UNI EN 1622 tubi acqua odore e sapore

DERIPLAST

EuroPas Evolution Solid wall PE 100 RC pipes (Resistant to Crack) type 1

Admin-2@tubiNet2024-07-02T09:26:52+02:00EuroPas Evolution – Solid wall PE 100 RC pipes (Resistant to Crack) type 1

BRIEF DESCRIPTION

Black high density polyethylene (HDPE) PE100 RC pipes (type1), with co-extruded blue stripes, for the transport of pressure water, for human consumption too, with product quality mark in compliance with (UNI) EN 12201-2 standard issued by an accredited independent organization according to UNI CEI EN ISO / IEC 17065/2012 and UNI CEI EN ISO / IEC 17020/2012 (certification of product conformity), and certified DIN PLUS in compliance with PAS 1075 technical standard.

MAIN FEATURES

Designed for trenchless tech. Installations

Higher service efficiency

More resistant to chemical agents

Compared to other materials

Longer life-span

Reduction / elimination of maintenance

Lower network management costs

Less disruption to users

Pipes completely compliant to the official standards

Correspondent to all types of connections

Advantageous cost/benefit ratio

Savings

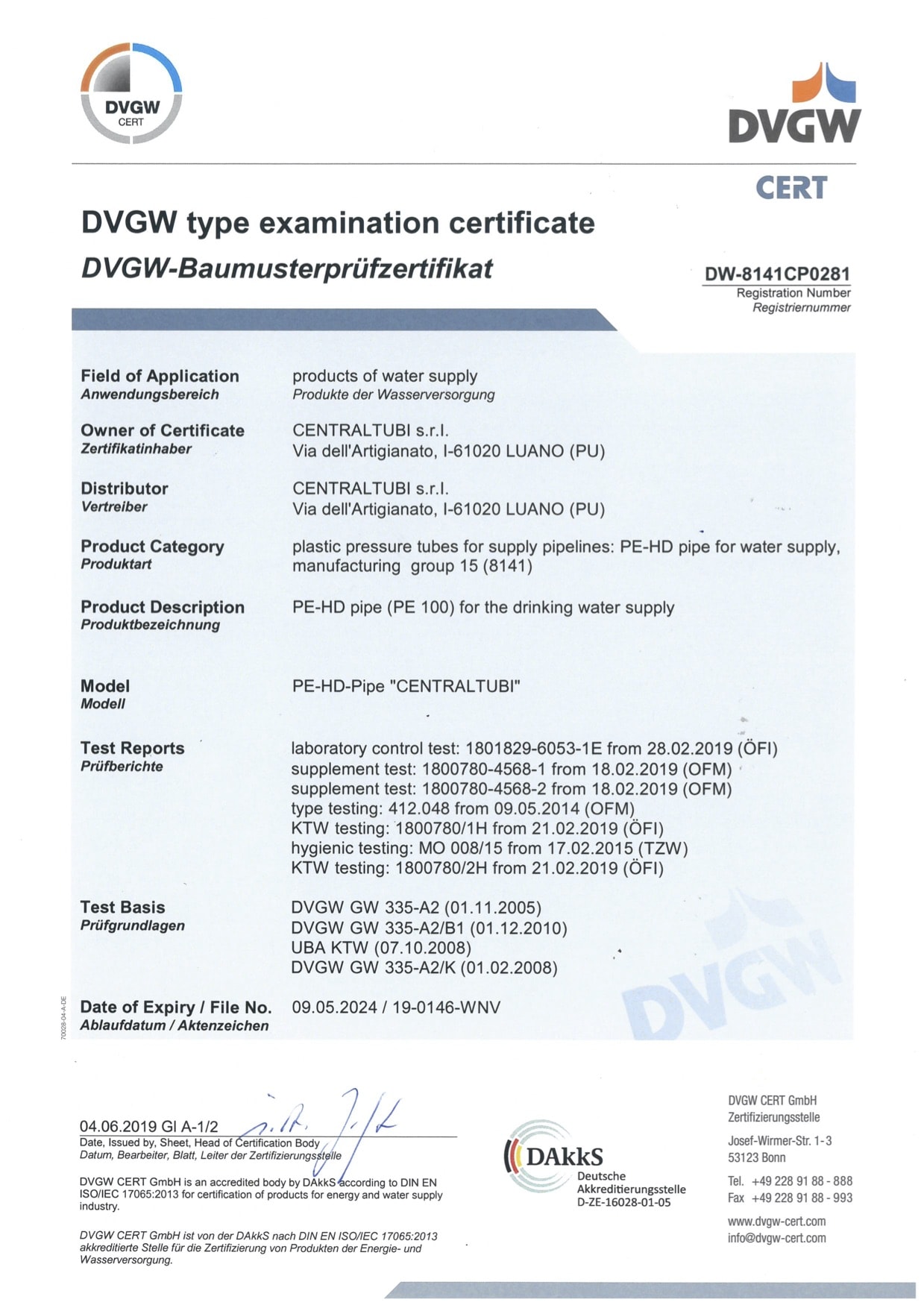

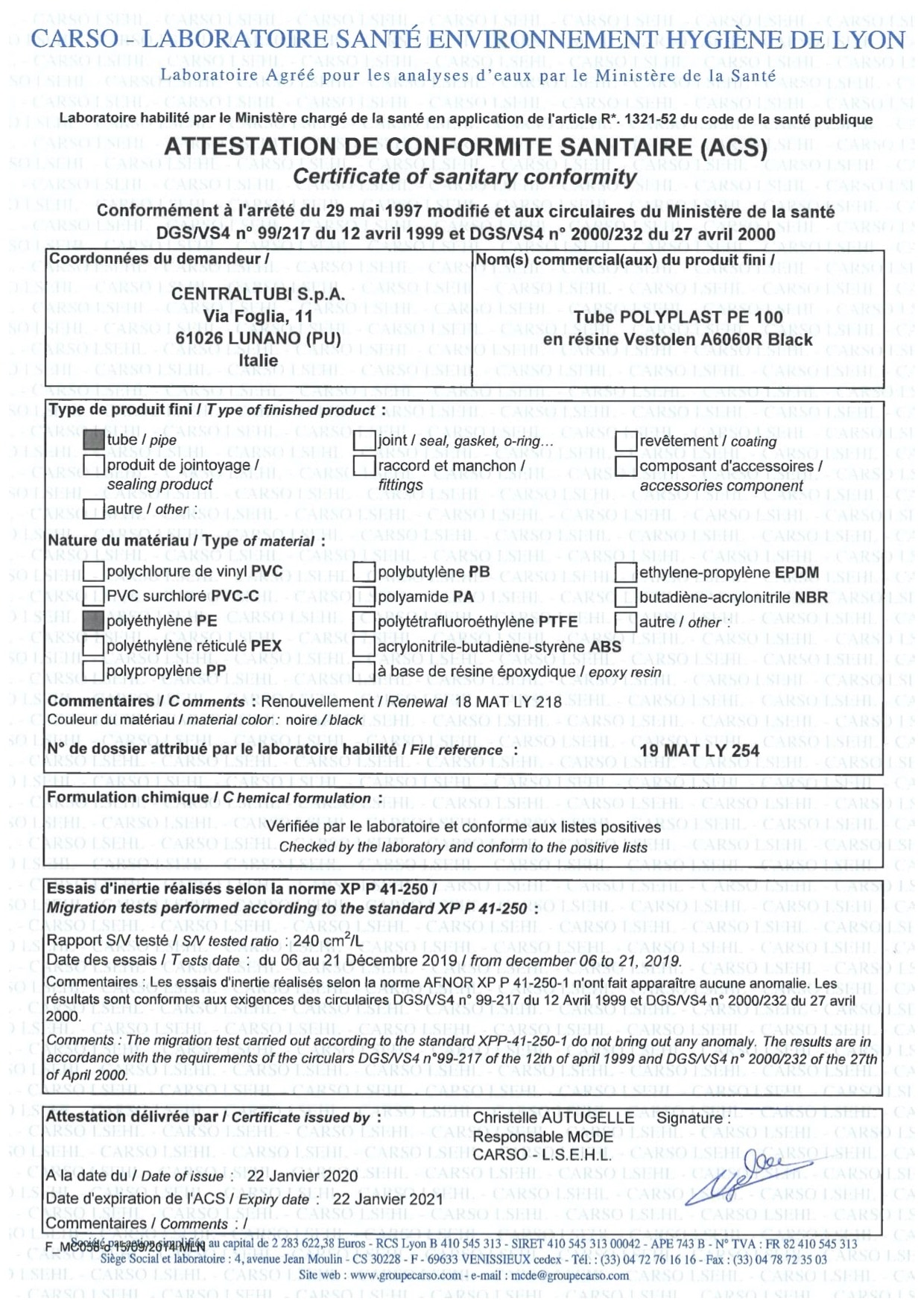

CERTIFICATES:

CENTRALTUBI

DIN CERTCO pas 1075 type 1 acqua up to 75

DIN CERTCO pas 1075 type 1 acqua 75 to 225

DIN CERTCO pas 1075 type 1 acqua 250 to 630

DIN CERTCO pas 1075 type 1 acqua 710

BureauVeritas PE100 UNI EN 12201 ACQUA

PiiP/C Europas Evolution Type 1

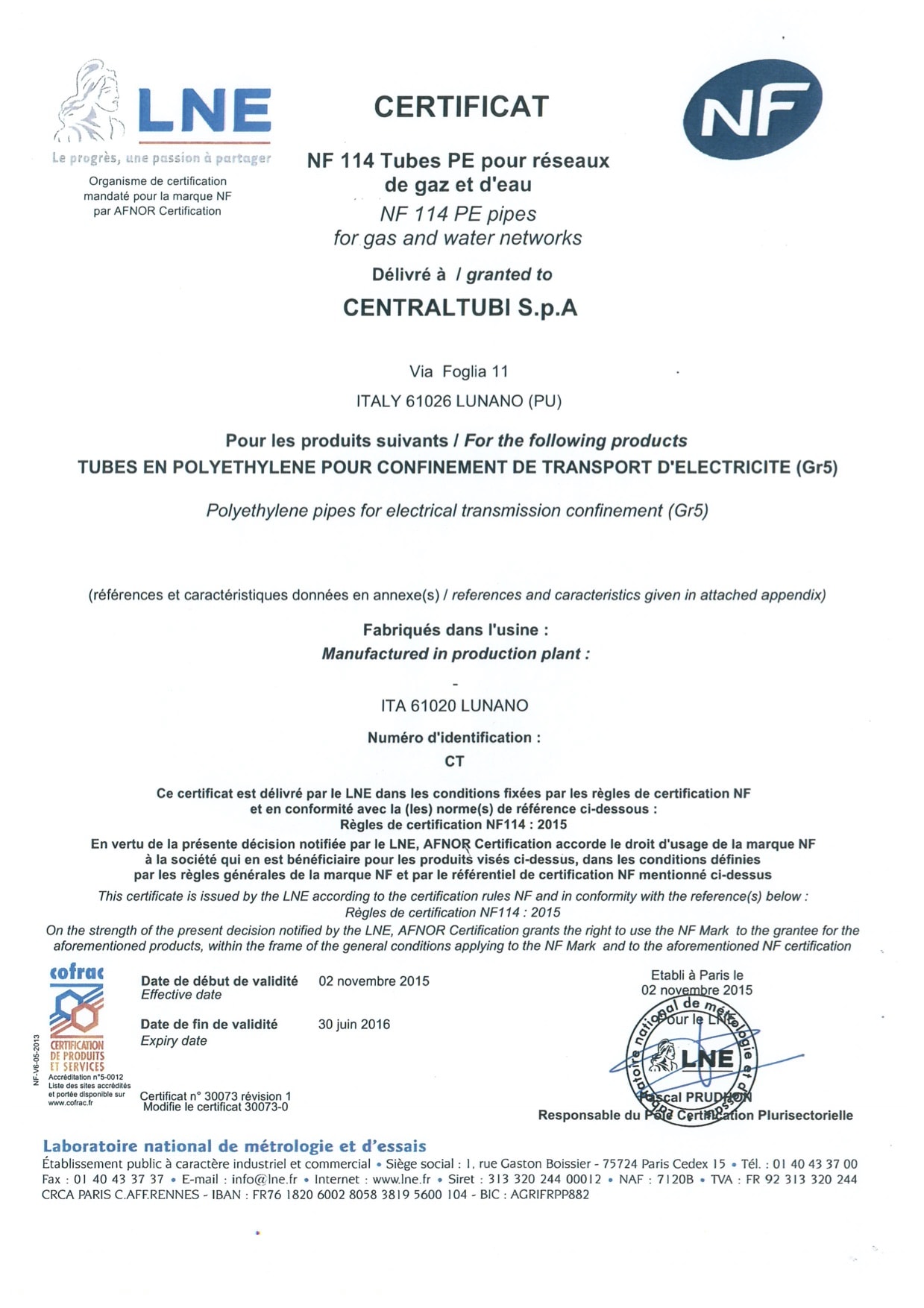

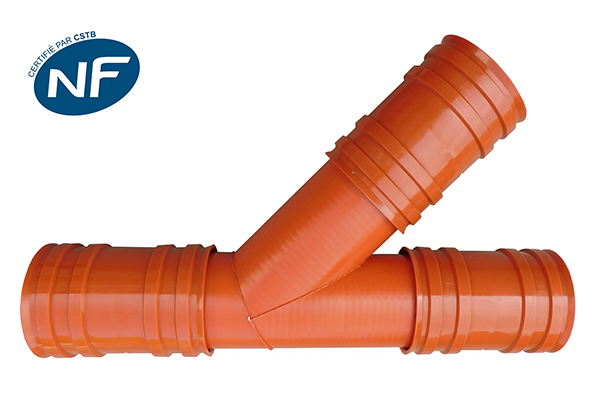

NF gruppo 2 acqua potabile in pressione

DERIPLAST

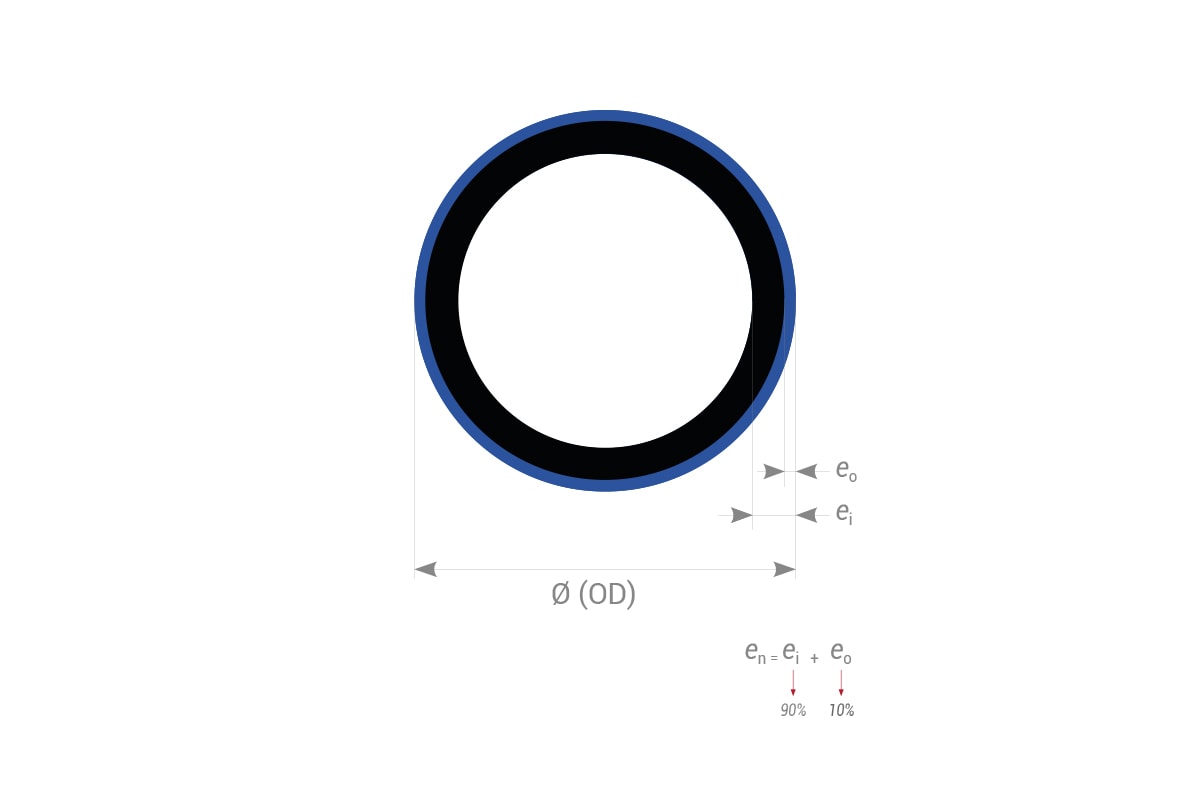

EUROPAS SAFE10 Solid wall PE 100 RC pipes (Resistant to Crack) type 2

Admin-2@tubiNet2024-07-02T09:27:15+02:00EUROPAS SAFE10 Solid wall PE100 RC pipes (Resistant to Crack) type 2

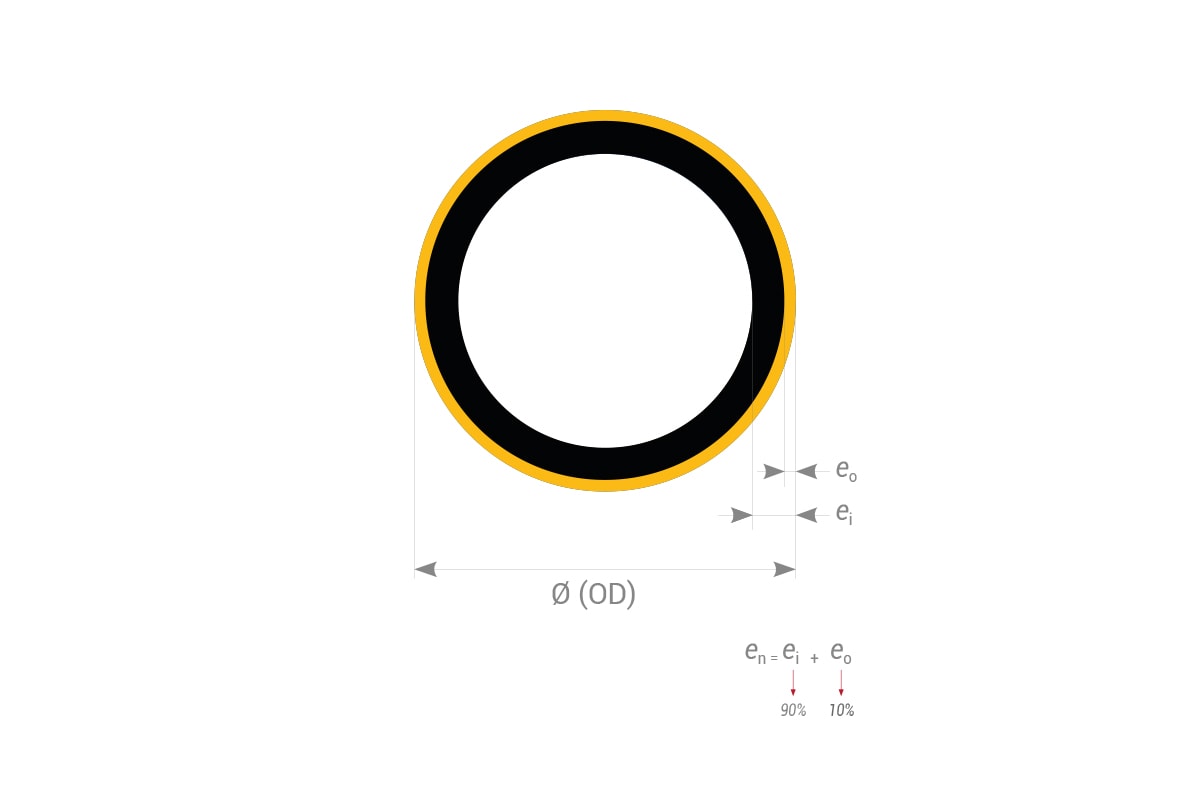

BRIEF DESCRIPTION

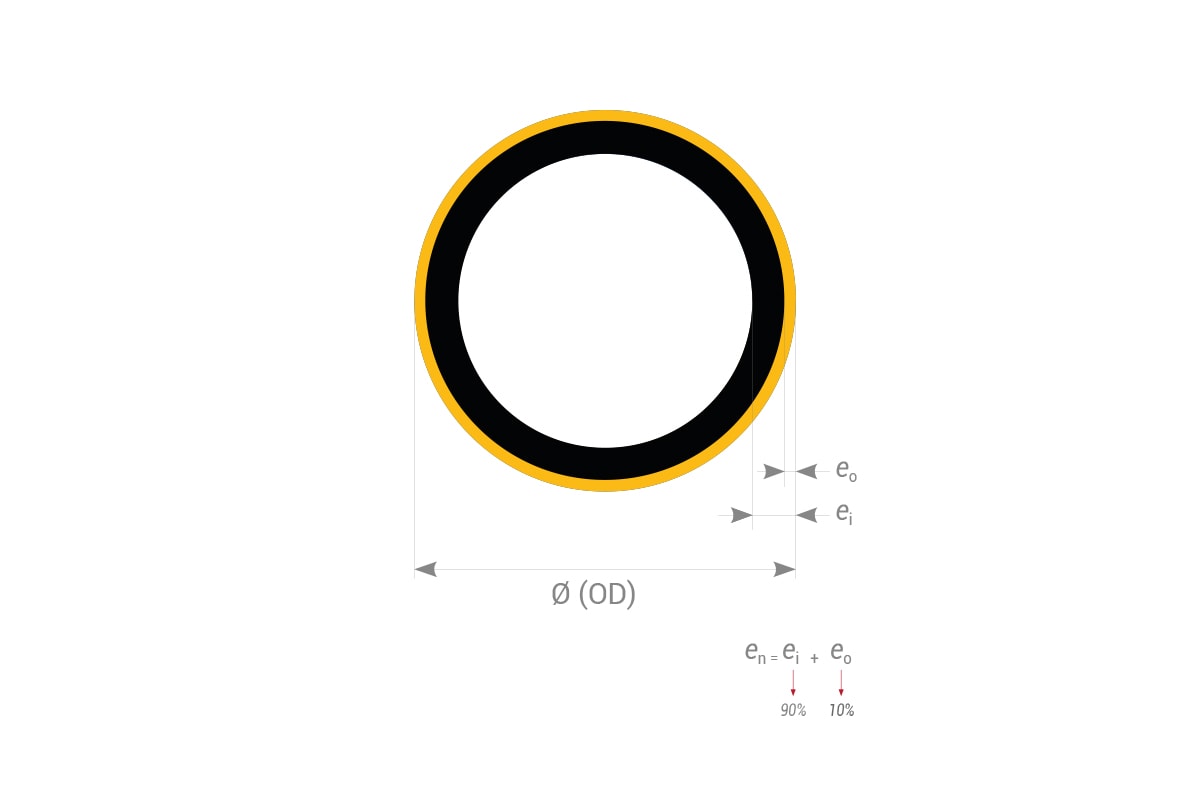

High density polyethylene (HDPE) PE100 RC pipes, made with black inner layer (90%) and with blue outer layer (10%) – type 2, for the transport of pressure water, for human consumption too, with product quality mark in compliance with (UNI) EN 12201-2 standard issued by an accredited independent organization according to UNI CEI EN ISO / IEC 17065/2012 and UNI CEI EN ISO / IEC 17020/2012 (certification of product conformity), and certified DIN PLUS in compliance with PAS 1075 technical standard.

MAIN FEATURES

Detection of obligation to repair damage

When deeper than the colored external wall

Reduction / elimination of maintenance

Lower network management costs

Higher service efficiency

Less problems for final users

Longer life-span

Pipes completely compliant to the various standards

Correspondent to all types of connections

Suitable for no-dig

More resistant to chemical agents

Advantageous cost/benefit rapport

Savings

Plug&Play – coupler/socket for PE pressure pipes

Admin-2@tubiNet2024-07-02T09:28:46+02:00Plug&Play – coupler/socket for PE pressure pipes

BRIEF DESCRIPTION

Push-to-connect double coupler made of polypropylene (PP) for PE pipes up to PN16, provided with double lip sealing gaskets and special anti-slipping rings. Elbow and tee shapes are available too. The diameters range (DN) goes from 20 up to 250 mm (OD pipes), but is also possible to request reduced sizes. The range for PE100 PN16 pipes from ɸ 20 to 63 mm requires the adoption of a “pipe liner” inside the end of the pipe to be connected. The socket version is made of PE from DN 90 up to 250 mm (PN 16-10), then butt-welded on one end of the pipe in the factory before the shipment (on-site welding is possible too).

MAIN FEATURES

High tightness reliability

Easy and fast to install

Wide range of diameters

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High shock absorption capacity

Recyclable

PE100 FLEX – PE100 PIPES WITH LOW APPLIED EFFORT FOR BENDING

Admin-2@tubiNet2024-07-02T09:29:15+02:00PE100 FLEX – PE100 PIPES WITH LOW APPLIED EFFORT FOR BENDING.

BRIEF DESCRIPTION

Solid wall pipes made of high density polyethylene, PE 100 (MRS 10 MPa – σS 8,0 MPa) with inner and outer smooth surface, available in black colour (with or without coextruded coloured stripe on the outer surface) with low applied effort for bending. The diameters range (OD) goes from 20 up to 1200 mm and pipes are delivered in coils and bars. They find application in pressurized and non-pressurized water systems.

MAIN FEATURES

100% permanent watertightness

Good flexibility

Reduction of the applied effort for bending compared to the one of the PE100 standard

Plastic behaviour in unstable situations

Wide range of diameters and pressure classes (sizing optimisation)

Wide range of fittings and special pieces, both standard and customised

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption ability

Recyclable

CERTIFICATES:

DCR – Solid wall PE 100 DCR pipes for chlorinated water networks

Admin-2@tubiNet2024-07-02T09:27:59+02:00DCR – Solid wall PE 100 DCR pipes for chlorinated water networks

BRIEF DESCRIPTION

Solid wall pipes made of PE 100 DCR (MRS 10 MPa – σS 8 MPa) with an inner and outer smooth surface, available in black colour (with or without external coextruded coloured stripes). The diameters range (OD) goes from 20 up to 1200 mm and pipes can be delivered in coils and bars. They are highly resistant to chlorine disinfectants used in water for human consumption.

MAIN FEATURES & BENEFITS

High resistance to chlorine aging effects DCR (Dioxide Chlorine Resistant)

100% permanent water tightness

Good bending properties

Plastic behaviour in unstable situations

Wide range of diameters and pressure classes (sizing optimization)

Wide range of fittings and special pieces, standard and customized

Related to aqueducts, this pipe is in conformity with the EN 1622 standard about “determination of threshold of smell and taste”

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

CERTIFICATES:

CENTRALTUBI

PE 100 DCR+RC Pipe

Admin-2@tubiNet2024-07-02T09:28:20+02:00PE 100 DCR PIPE

SPECIFICATION ITEM

Pipe in PE – RD (Resistant to Chlorine Dioxide).

TECHNICAL SPECIFICATION

High density polyethylene pipes entirely made of PE100 resin (MRS ≥ 10 MPa) with high resistance to chlorine components (Clo2) dissolved in water, fully complying with the standard EN 12201. The marking shall report in full the code of the raw material used for the production of the pipe, as well as other elements required by the reference standards.

Thus EUROPE DCR emerges, and provides additional value to the pipe while increasing its longevity also, against the degrading effects of chlorine. Expectations of durability of operation of these pipes stretch significantly, increasing the value and management efficiency of the networks.

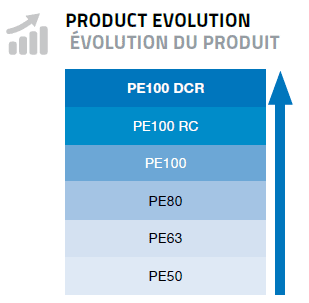

DEVELOPMENT OF THE PRODUCT

The term RD (Resistant to Chlorine Dioxide) refers to PE100 pipes with higher durability against the degrading activity of chlorine (Clo2) and other chlorine agents, the latter one being increasingly used for the sanitation of drinking water.

FEATURES AND ADVANTAGES

- High tensile strength

- High resistance to chlorine aging effect

- Higher durability for the transport of drinking water

- Economies: lower costs for maintenance and repair

CERTIFICATES:

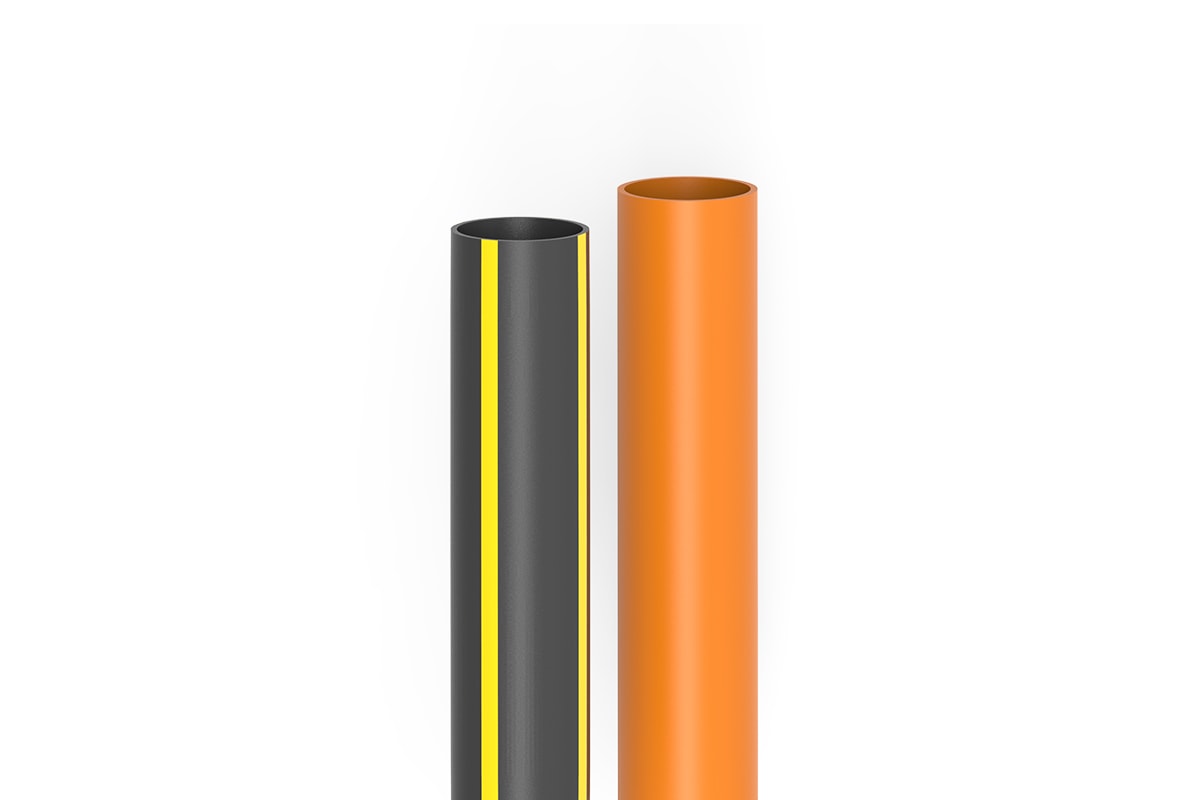

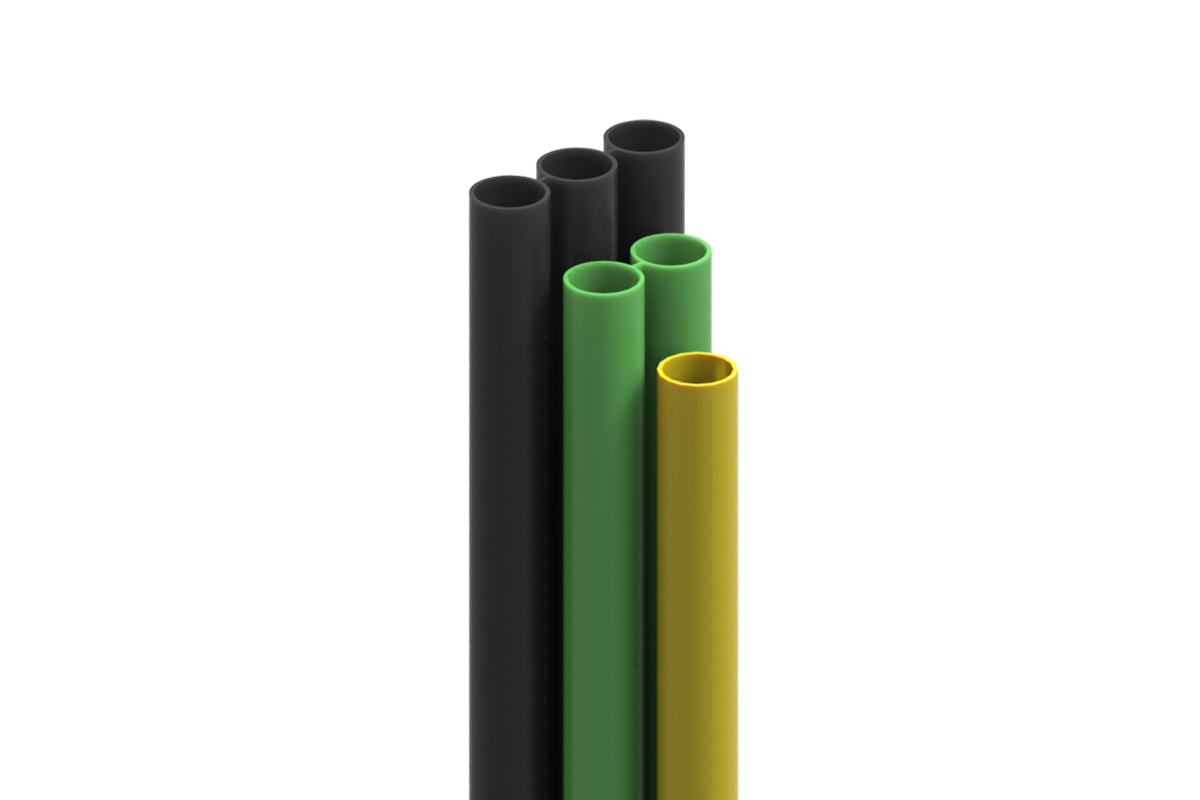

PE 80 Pipe for gas networks

Admin-2@tubiNet2021-06-07T11:26:34+02:00PE 80 Pipe For Gas Networks

BRIEF DESCRIPTION

Solid wall pipes made of PE 80 (MRS 8 MPa) with a smooth inner and outer surface, available in black colour with external coextruded yellow stripes or completely yellow.

Diameters (OD) go from 20 up to 800 mm. Pipes can be delivered in coils and bars, for the construction of GAS distribution system.

MAIN FEATURES

100% permanent gas tightness;

Good bending properties, particularly appreciated in manual applications in colder climate;

Low modulus of elasticity;

Plastic behavior in unstable situations

Wide range of diameters (sizing optimization);

Wide range of standard fittings;

Inert to stray currents;

High chemical resistance (ISO/TR 10358);

High shock absorption capacity

Recyclable

PE 100 Pipe for gas networks

Admin-2@tubiNet2024-07-02T09:29:45+02:00PE 100 Pipe for gas networks

BRIEF DESCRIPTION

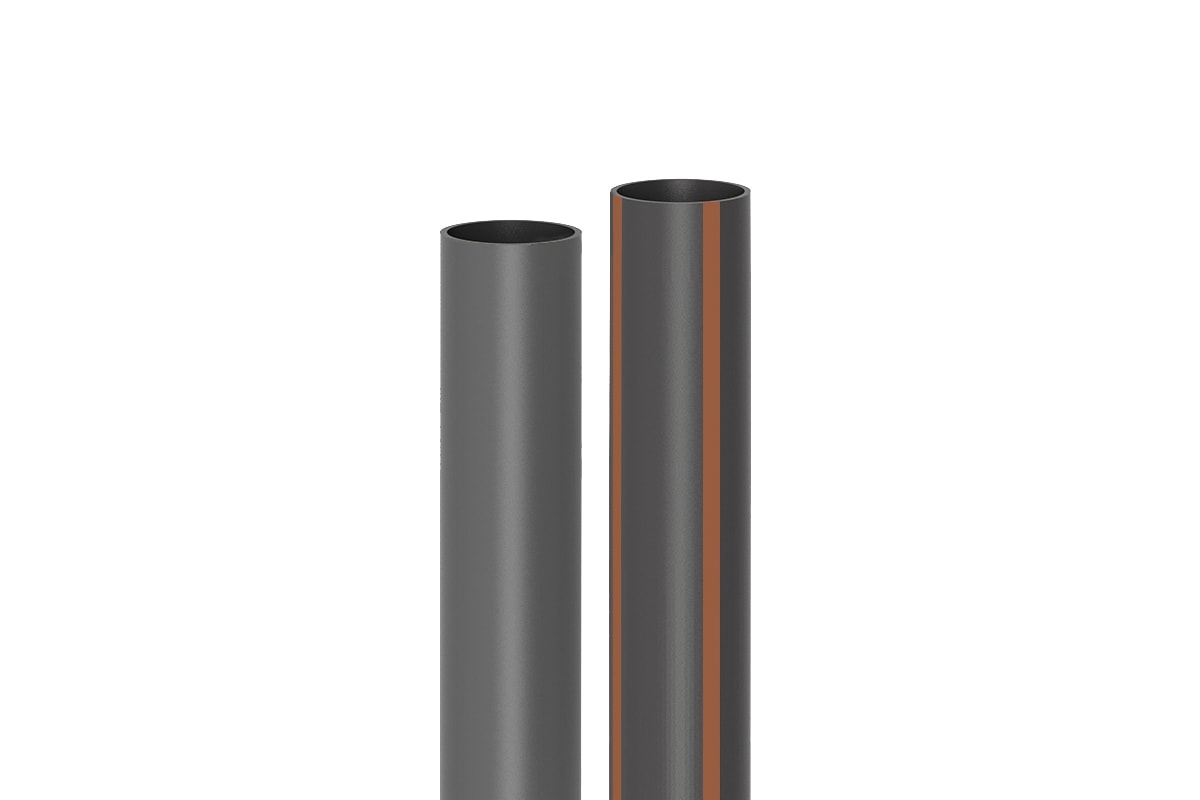

Solid wall pipes made of PE 100 (MRS 10 MPa) with a smooth inner and outer surface, available in black colour with external coextruded orange stripes or completely yellow.

Diameters (OD) go from 20 up to 800 mm. Pipes can be delivered in coils or bars and find application in gas networks.

MAIN FEATURES

100% permanent gas tightness

Plastic behaviour in unstable situations

Wide range of diameters (sizing optimization)

Wide range of standard fittings

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High shock absorption capacity

Recyclable

CERTIFICATES:

LUCANIA RESINE

EuroPas Evolution – Solid wall PE 100 RC pipes (Resistant to Crack) type 1 for gas

Admin-2@tubiNet2024-07-02T09:30:09+02:00PE100 RC type 1 Pipe for gas “Europas Evolution”

BRIEF DESCRIPTION

Solid wall pipes made of PE 100 RC (MRS 10 MPa) with high resistance to Slow Crack Growth (SCG), smooth on the inside and the outside. Type 1 (1 layer) is available in black colour (with external orange coextruded stripes) or completely orange.

Diameters (OD) go from 20 up to 800 mm. Pipes can be delivered in coils or bars and they are used for the construction of GAS distribution systems.

MAIN FEATURES

High resistance to SCG from point loads and surface incisions

Particularly recommended for NO DIG installation techniques

100% permanent water tightness

Good bending properties

Plastic behaviour in unstable situations

Wide range of diameters (sizing optimization)

Wide range of standard fittings

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

EUROPAS SAFE10 – Solid wall PE 100 RC pipes (Resistant to Crack) type 2 for gas

Admin-2@tubiNet2024-07-02T09:30:37+02:00PE100 – RC type 2 pipe for gas”Europas Safe10″

BRIEF DESCRIPTION

Solid wall pipes made of PE 100 RC (MRS 10 MPa) with high resistance to Slow Crack Growth (SCG), smooth on the inside and the outside. Type 2 (2 layers) is available with inner black colour wall (90% of the thickness) + outer orange colour wall (10% of the thickness).

Diameters (OD) go from 20 up to 450 mm. Pipes are delivered in coils or bars and are used for the construction of GAS distribution systems.

MAIN FEATURES

High resistance to SCG from point loads and surface incisions

Particularly recommended for NO DIG installation techniques

100% permanent water tightness

Good bending properties

Plastic behaviour in unstable situations

Wide range of diameters (sizing optimization)

Wide range of standard fittings

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

It is recyclable

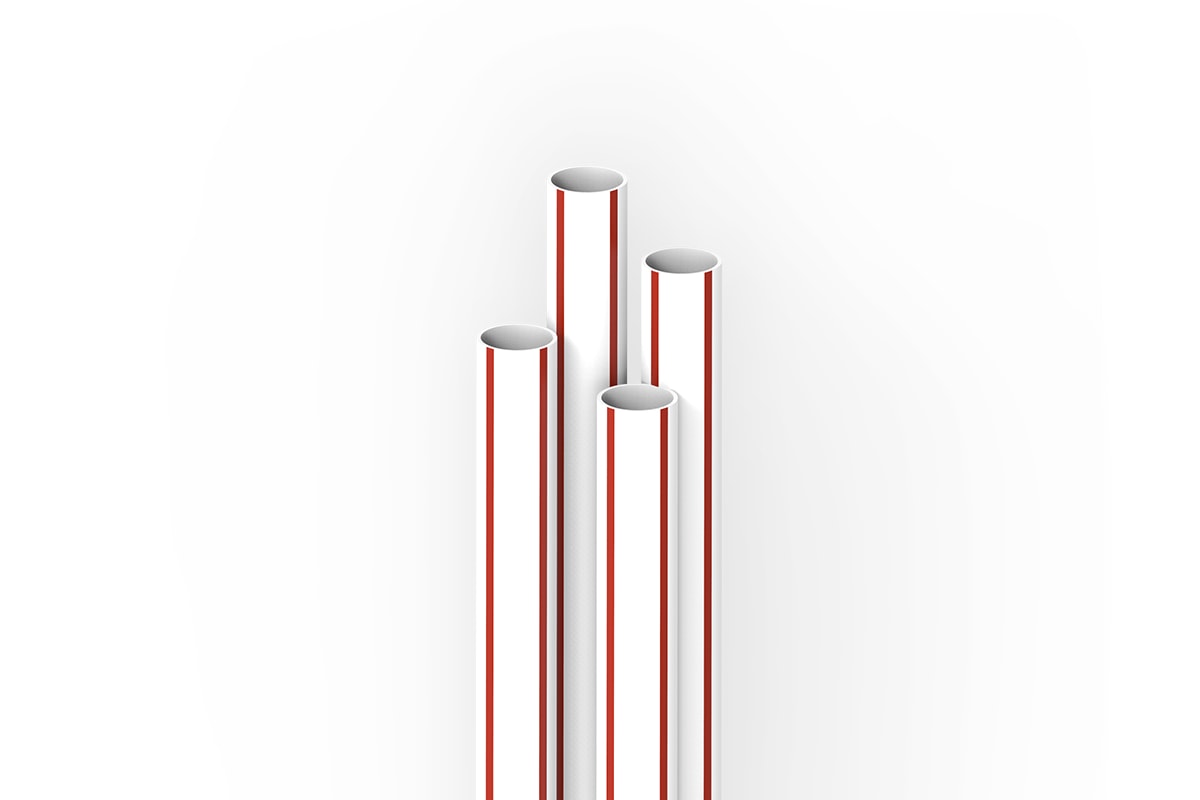

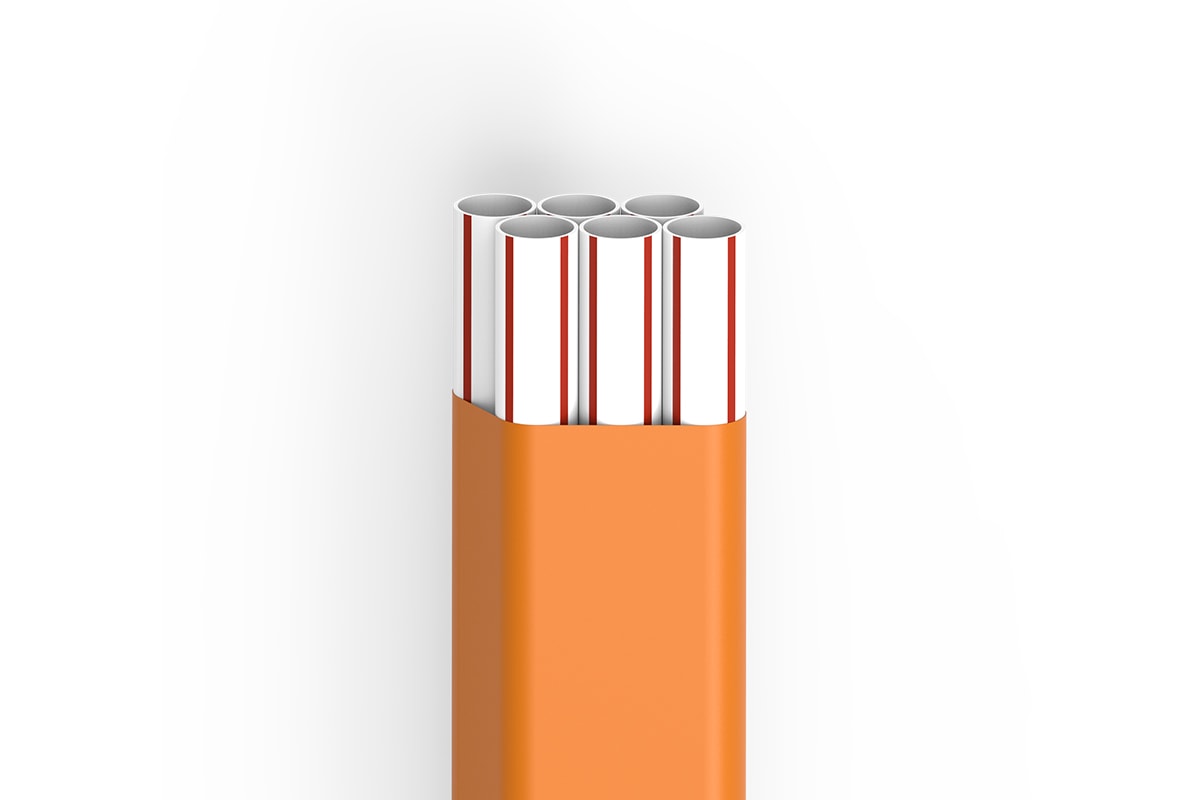

HDPE solid wall pipes for underground cable protection

AdminExport@tubiNet2024-07-01T15:35:28+02:00HDPE solid wall pipes for underground cable protection

BRIEF DESCRIPTION

High density polyethylene (HDPE) pipes with a solid wall profile, internally and externally smooth, black with/without red coextruded stripes on the external surface, connectable by buttfusion welding (verified according to ISO 13953) in order to be suitable also for the execution of trenchless installations (HDD, Pipe Bursting …)

In order to ensure the normal operation of the system with cable temperatures up to 80ºC and short-circuit temperatures (not exceeding 5 seconds) up to 160ºC, the mechanical characteristics of the pipe meet the requirements of the following standards:

- CEI EN 61386–1–24 (from ɸ 25 up to ɸ 250 mm)

- IEC 62067: Verification of the mechanical characteristics of HDPE conduits for cable with nominal voltages from 150 to 500 kV, before and after thermal aging

- ENA TS 12-24: verification of crushing strain resistance at 50ºC (Group 2) and 75ºC (Group 1)

Range of diameters included:

- all those required by CEI EN 61386, in various thicknesses for the different classes of ring stiffness

- all sizes up to ɸ 1200 mm, with reference to the SDR classes standardized by EN 12201-2

MAIN FEATURES & BENEFITS

IMQ quality mark certified according to 61386-1-24 standard (size range from ɸ 25 up to ɸ 250 mm)

CE marking*

On request: PSV mark (Plastica Seconda Vita – Second Life Plastic) – Circular Economy model

100% permanent watertight seal

Pliability (according to tab.1 below)

plastic behaviour in unstable situations

wide range of fittings and special parts, standard and customized

inertia to stray currents

high chemical resistance (ISO/TR 10358– ISO/TR 7474)

high shock absorption capacity

totally recyclable

CONNECTIONS between the elements

- compression fittings up to DN 110 mm

- push-fast fittings “Plug&Play” from DN 16 up to 250 mm

- butt-fusion welding (NO for trenchless installation techniques)

- electro-fusion welding

- PE injection molded couplers “NRG” (IP 66-68) for DN 160 + 200 + 225 + 250 mm

* for the diameter range included in standard 61386

HDPE solid wall pipes for HIGH VOLTAGE cables protection

admin@tubi2024-07-01T15:35:15+02:00HDPE solid wall pipes for cable protection HIGH VOLTAGE

ELECTROPIPE – HV

BRIEF DESCRIPTION

High density polyethylene (HDPE) pipes with a solid wall profile, internally and externally smooth, black with red coextruded stripes on the external surface, connectable by butt polyfusion welding (verified according to ISO 13953) in order to be suitable also for the execution of trenchless poses (TOC).

In order to ensure the normal operation of the system with cable temperatures up to 80 ºC, and short-circuit temperatures (not exceeding 5 seconds) up to 160º C, the mechanical characteristics of the pipe meet the requirements of the following standards:

- IEC 62067: Verification of the mechanical characteristics of HDPE conduits for cable insulation for nominal voltages from 150 to 500 kV, before and after thermal aging

- ENA TS 12-24: verification of crushing strain resistance at 50 ºC and 75 ºC

The range of diameters includes:

- all those required by CEI EN 61386, ɸ 25 to 250 mm, in various thicknesses for the different classes of annular rigidity

- all sections up to ɸ 1200 mm, with reference to the SDR classes required by EN 12201-2

MAIN FEATURES & BENEFITS

- IMQ certified standard 61386*

- CE marking*

- with PSV brand (Second Life Plastic) on request – Circular Economy

- PE joint system with EPDM sealing seals, with IP66 and IP68 protection rating for ɸ 200 – 225 – 250 mm pipes

- head/head and electrofusion joining system possible

- 100% permanent watertight seal

- internally and externally bevelled ends

- Wide Radius Foldability

- low elastic modulus

- plastic behaviour in unstable situations

- wide range of fittings and special parts, standard and customized

- inertia to stray currents

- high chemical resistance (ISO/TR 10358 – ISO/TR 7474)

- High shock absorption capacity

- total recyclability

* for the diameter range included in standard 61386

SPECIFICATION ITEMS

HDPE pipes for underground cable threading systems according to CEI EN 61386

Supply and installation of high-density polyethylene (HDPE) pipes, with solid wall profile, smooth internally and externally, black with coextruded red stripes on the external surface, for the construction of underground cable threading systems. The pipes must be equipped with a mark of conformity of the product to the standard CEI EN 61386-1-24 issued by an accredited third-party certification body, with crush resistance class ≥ … N and impact resistance classification “N series”.

Piping must be tested according to ISO 13953 by accredited third party to verify conformity to butt welds. The mechanical characteristics of HDPE cable insulation pipes with nominal voltages from 150 to 500 kV shall be verified according to IEC 62067, before and after thermal ageing. The verification of crushing deformation resistance at 50 ºC and 75 ºC shall be verified according to ENA TS 12-24. The marking of the pipes must bear in full all the elements required by the reference standard, in addition to the product quality mark and the CE marking. The pipe manufacturer must be regularly registered with the PolieCo Consortium (D.Lgs. 152/2006 – art. 234).

HDPE pipes – class 450* N

ɸ 50 mm (sp. 3,0 mm)

… ….. …

ɸ 200 mm (sp. 9,6 mm)

ɸ 225 mm (sp. 10,8 mm)

ɸ 250 mm (sp. 11,9 mm)

* Standard ring stiffness classes: 450 N – 750 N – >750 N

HDPE pipes for underground cable threading systems

for custom sizes not included in CEI EN 61386

Supply and installation of high-density polyethylene (HDPE) pipes, with solid wall profile, smooth internally and externally, black with coextruded red stripes on the external surface, for the construction of underground cable threading systems. The HDPE material of the pipes must meet the requirements of CEI EN 61386-1, and the normalized dimensional ratio must be SDR … according to UNI EN 12201-2. Piping must be tested according to ISO 13953 by accredited third party to verify conformity to butt welds. The mechanical characteristics of HDPE cable insulation pipes with nominal voltages from 150 to 500 kV shall be verified according to IEC 62067, before and after thermal ageing. The verification of crushing deformation resistance at 50 ºC and 75 ºC shall be verified according to ENA TS 12-24. The marking of the pipes must bear in full all the identifying elements of the product and the manufacturer, and repeat at intervals not exceeding 1 m. The manufacturer of pipes must be regularly registered with the mandatory PolieCo Consortium (D.Lgs. 152/2006 – art. 234).

HDPE pipes – SDR17*

… ….. …

ɸ 200 mm (sp. 11,9 mm)

ɸ 225 mm (sp. 13,4 mm)

ɸ 250 mm (sp. 14,8 mm)

… ….. …

ɸ 1200 mm (sp. 71,1 mm)

Standards: SDR26 (SN4) – SDR21 (SN8) – SDR17 (SN16) – SDR11 (SN64)

Upon request, this type of pipe can also be equipped with Pipe Tracer system, so as to become:

- traceable with high plano-altimetric accuracy

- referential (containing information on the type of service and its management)

HDPE solid wall pipes for non-pressure networks

Admin-2@tubiNet2024-07-02T09:24:28+02:00HDPE solid wall pipes for non-pressure networks

BRIEF DESCRIPTION

Solid wall pipes made of high density polyethylene (HDPE) with a smooth inner and outer surface, available in black colour (with or without external coextruded coloured stripes). The diameters range (OD) go from 20 up to 1200 mm and pipes are delivered in bars.

MAIN FEATURES

100% permanent water tightness

Long-range bending

Low modulus of elasticity

Plastic behaviour in unstable situations

Wide range of fittings and special pieces, standard and customized

Inert to stray currents

High abrasion and chemical resistance (ISO/TR 10358)

High shock absorption capacity

Recyclable

CERTIFICATES:

Solid wall HDPE pipes for pressurized sewerage networks

Admin-2@tubiNet2022-12-14T12:00:41+01:00Solid wall HDPE pipes for pressurized sewerage networks

TECHNICAL SPECIFICATION

HDPE solid wall pipes, black, or black with brown stripes, for gravity sewerage systems.

FOR THE PIPES CORRESPONDING TO THE NORM

Completely compliant with UNI EN 12666-1, with nominal diameter … mm, ring stiffness class SN …

FOR THE PIPES WITH PSV MARK

The pipes shall have the appearance, dimensions, physical and mechanical properties according to UNI EN 12666-1, with external nominal diameter …mm, ring stiffness class SN… . The pipes shall be entirely produced of HPDE obtained through revalorization of plastic scraps from separate waste, according to UNI 10667. The production chain of raw material shall be guaranteed by PSV Mark (Plastica Seconda Vita). with environmental branding according to UNI EN ISO 14021, certified by IIP. Product marking shall bear all the information necessary to trace the origin of the raw matter, and the corresponding mark, which guarantees the material origin.

FOR PRESSURISED SYSTEMS

Supply of HDPE black, or black with brown stripes pipes, for sewerage under pressure or in depression. The nominal external diameter is …mm, SDR … (PN…), completely complying to the UNI EN 12201-2, with certificate issued by third party accredited according to UNI CEI EN ISO/IEC 17065 and UNI CEI EN ISO / IEC 17020 (certification of product compliance).

CERTIFICATES:

Solid wall PE 100 RC (Resistant to Crack) pipes type 1 for pressurized sewerage networks

Admin-2@tubiNet2022-12-21T08:48:38+01:00Solid wall PE 100 RC (Resistant to Crack) pipes type 1 for pressurized sewerage networks

BRIEF DESCRIPTION

High density polyethylene pipes PE 100 RC (MRS 10 MPa – σS 8,0 MPa) with smooth inner and outer surface and high resistance to Slow Crack Growth (SCG). Type 1 (1 layer) is available in black colour (with or without coextruded brown stripes on the outer surface). The diameters range (OD) goes from 75 up to 1200 mm and pipes are delivered in bars.

MAIN FEATURES

100% permanent water tightness

Good flexibility

Plastic behaviour in unstable situations

Wide range of diameters and pressure classes (sizing optimization)

Wide range of fittings and special pieces, standard and customised

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

CERTIFICATES:

Solid wall PE 100 RC (Resistant to Crack) pipes type 2 for pressurized sewerage networks

Admin-2@tubiNet2022-12-21T08:57:28+01:00Solid wall PE 100 RC (Resistant to Crack) pipes type 2 for pressurized sewerage networks

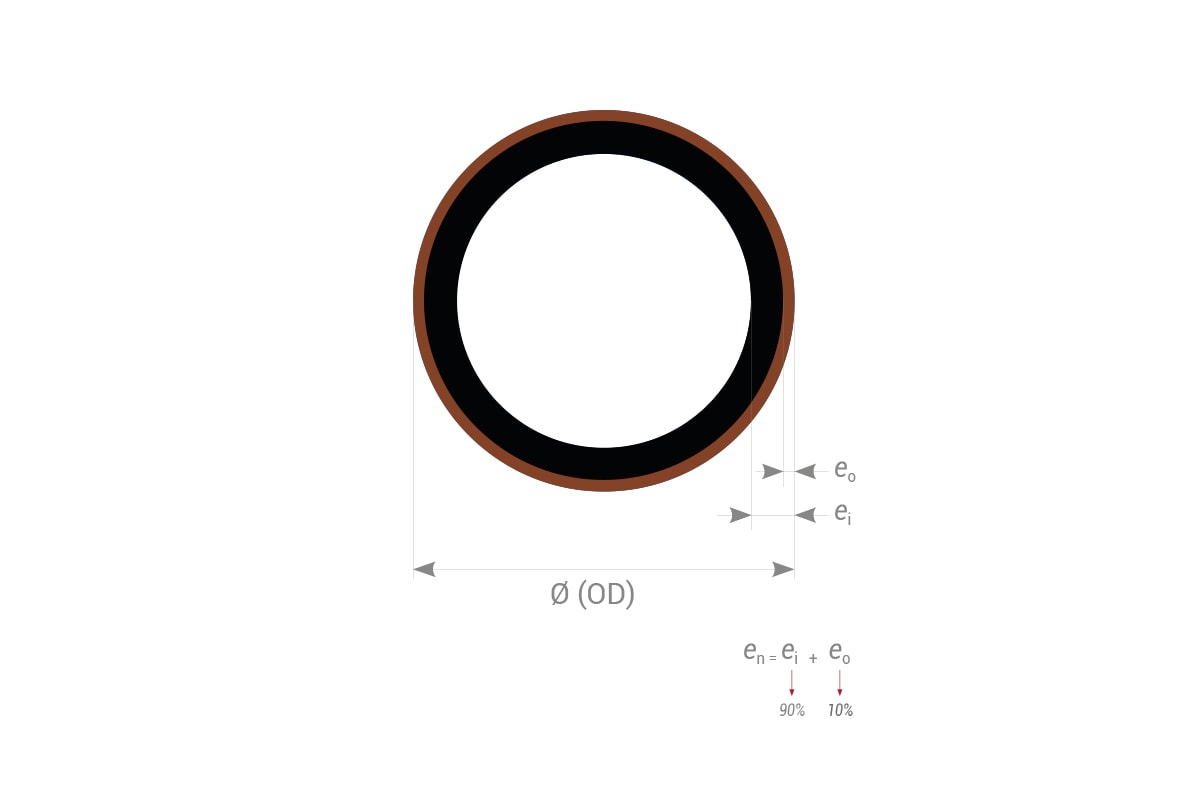

BRIEF DESCRIPTION

High density polyethylene pipes PE 100 RC (MRS 10 MPa – σS 8,0 MPa) with a smooth inner and outer surface and high resistance to Slow Crack Growth (SCG). Type 2 (2 layers) is available with inner black colour wall (90% of the thickness) + outer brown colour wall (10% of the thickness). The diameters range goes from 75 up to 450 mm and pipes are delivered in bars.

MAIN FEATURES

100% permanent water tightness

Good flexibility

Plastic behaviour in unstable situations

Wide range of diameters and pressure classes (sizing optimization)

Wide range of fittings and special pieces, standard and customised

Inert to stray currents

High chemical resistance (ISO/TR 10358)

High abrasion resistance

High shock absorption capacity

Recyclable

CERTIFICATES:

SGK HDPE spiral pipes for sewer and drainage systems

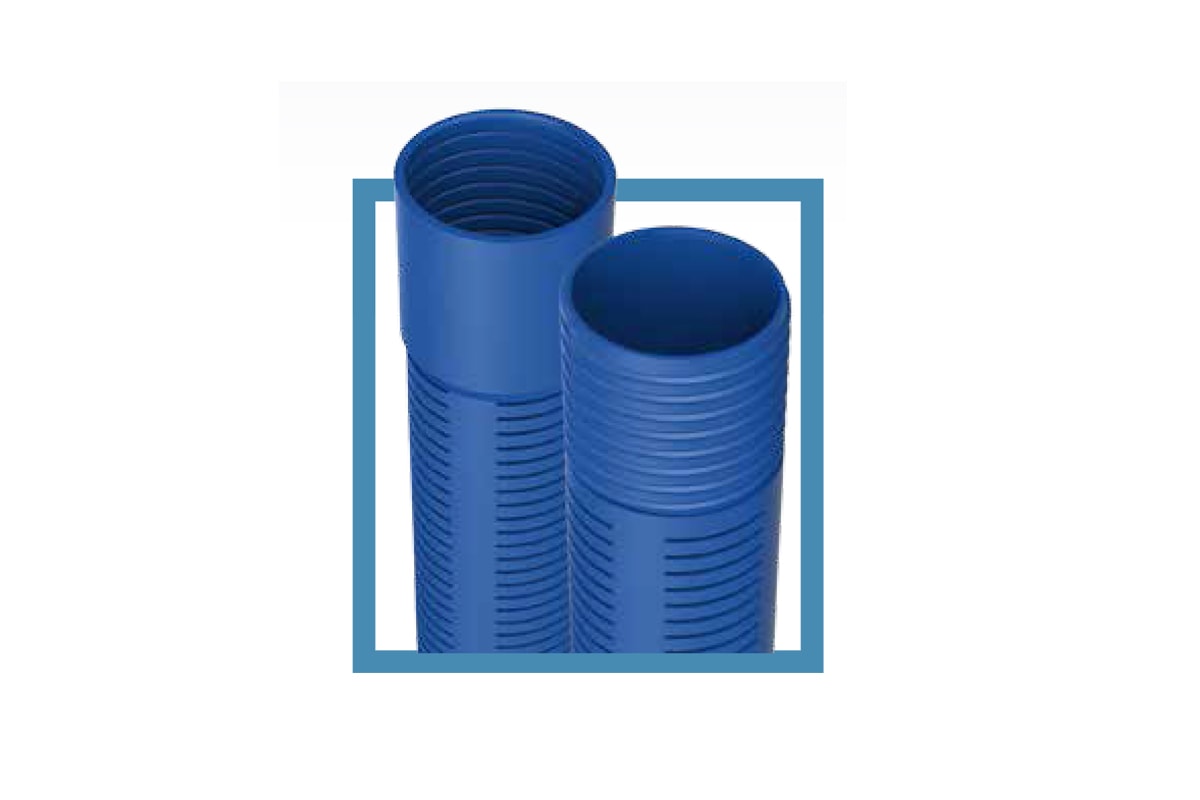

Admin-2@tubiNet2024-07-04T13:51:58+02:00SGK HDPE spiral pipes for sewer and drainage systems

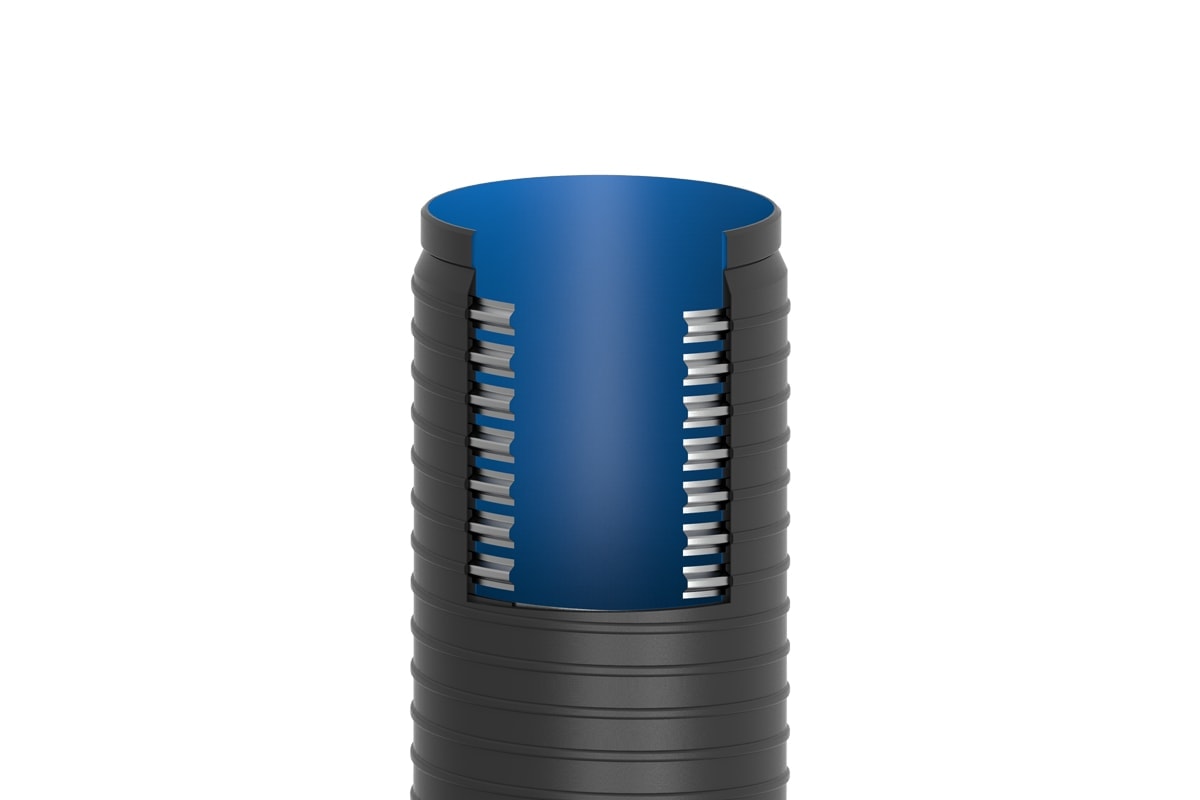

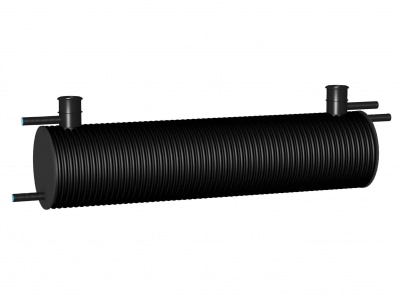

BRIEF DESCRIPTION

HDPE structured wall pipes made through spiral winding technology which find application in non-pressure underground sewerage and drainage systems. Other possible applications are for: culverts (road and railway embankments crossing) syphons, under low pressure operating networks and for construction of inspection manholes, water storage and waste wastewater treatments. They consist of a smooth inner surface for water flowing and a smooth or profiled outer one (in different shapes and sizes) that determines the ring stiffness. All pipe lengths are provided with an integrated junction socket and the respective spigot for the electrofusion or with grooves for the sealing gasket junction system. The diameters range (DN/ID) goes from 800 up to 2500 mm.

Ring stiffness:

| Standard EN 13476 | Standard DIN 16961 |

| SN2 (2 kN/m2) | Class 3 (SR24 8 kN/m2) |

| SN4 (4 kN/m2) | Class 4 (SR24 16 kN/m2) |

| SN8 (8 kN/m2) | Class 5 (SR24 31,5 kN/m2) |

| SN16 (16 kN/m2) | Class 7 (SR24 125 kN/m2) |

The two classifications of the ring stiffness according to the two distinct standards are not correlated, as they are data obtained through tests with different methods and times.

MAIN FEATURES

Wide range of diameters

Smooth or profiled outer surface

Wide range: of structured profiles à moment of inertia àring stiffness

Integrated socket connections with the electrofusion technology

High reliability of connections tightness

Socket and gasket connection system available

Lightweight and easy to install

High chemical and abrasion resistance

Inert to stray currents

Color availability: entirely black or blue inside/black outside

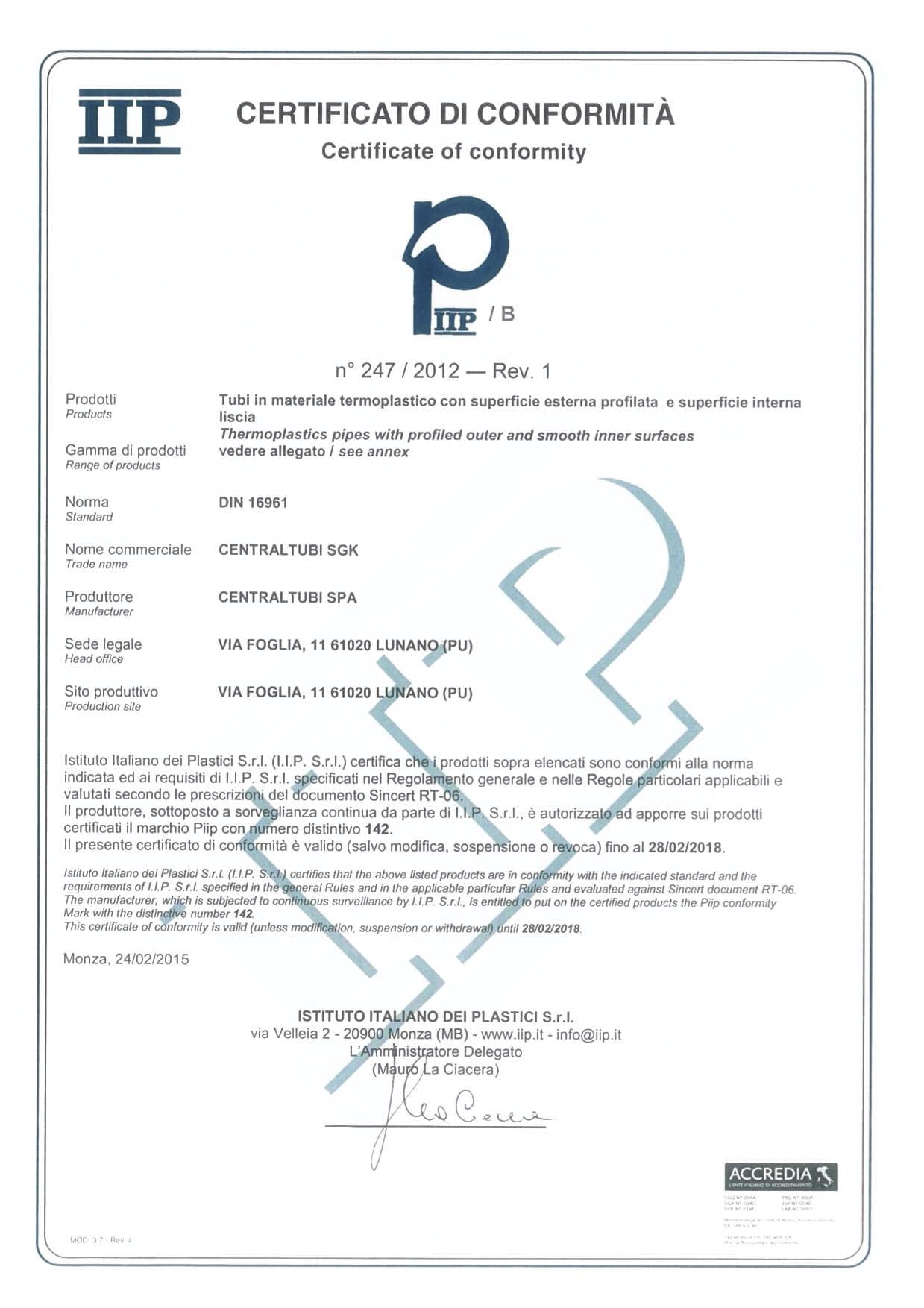

CERTIFICATES:

SGS – Composite PE + steel spiraled pipes for non-pressure networks

Admin-2@tubiNet2021-07-09T10:46:37+02:00SGS – Composite PE + steel spiraled pipes for non-pressure networks

BRIEF DESCRIPTION

Structured wall pipes made through spiral winding technology that consist of composite profiles of PE and steel. They find application in non-pressure underground sewerage and drainage systems and road embankment crossing. The profiles consists of a smooth inner wall for water flowing, a middle steel section, all coated by a smooth outer surface of PE. All pipe lengths are provided with an integrated junction socket and the respective smooth spigot for the electrofusion or with grooves for the sealing gasket junction system. The diameters range (DN/ID) goes from 800 up to 2000 mm.

Ring stiffness:

| CLASS | A | B | C |

| Rigidity |

PS

kPa |

||

| Pipe deflection = 3% | 415 | 620 | 830 |

| Pipe deflection = 5% | 325 | 485 | 645 |

| Pipe deflection = 8% | 215 | 325 | 430 |

The assembly method used to put together the inner and outer PE walls and the middle steel profile is mechanical (not chemical from adhesive substances).

MAIN FEATURES

Wide range of diameters

Flat outer surface

PE and steel profiles are putted together using a mechanical assembly method (no use of chemical tackifiers)

Socket connections with electrofusion technology or with sealing gasket

High reliability of connections tightness

Lightweight and easy to install

High chemical and abrasion resistance

Inert to stray currents

CERTIFICATES:

CENTRALTUBI

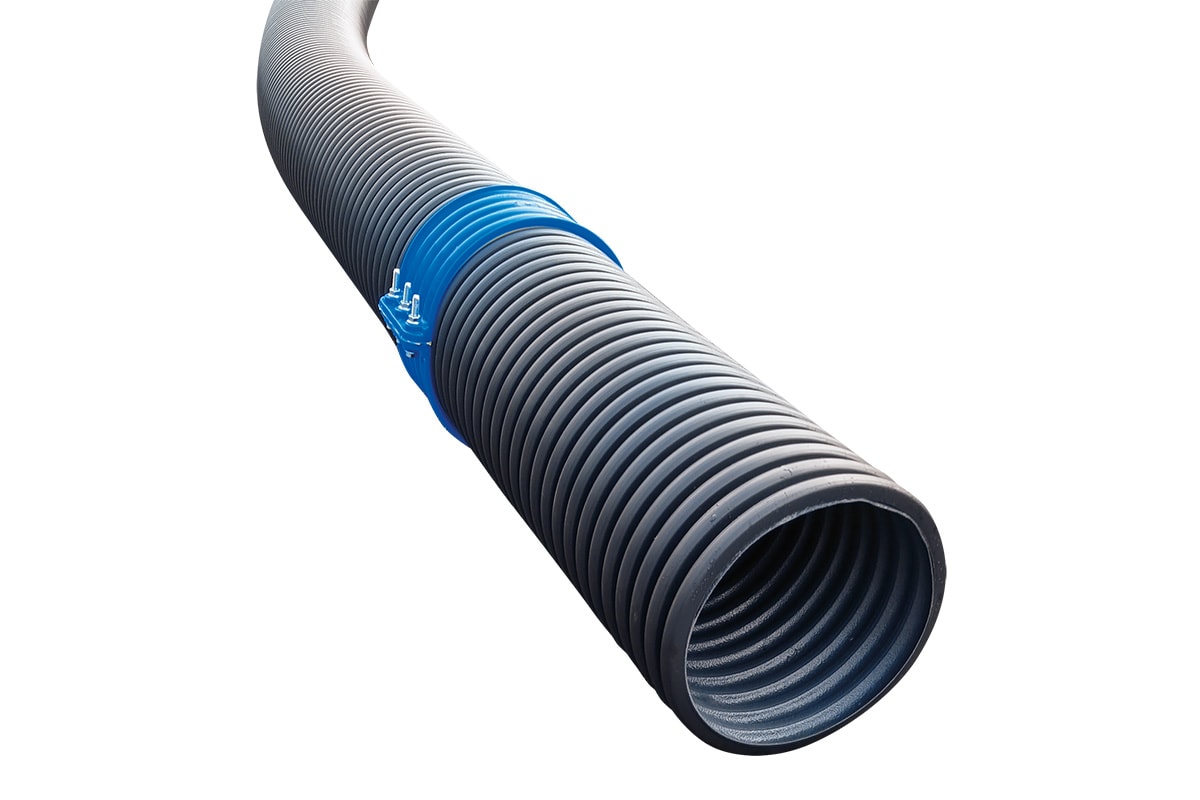

CorPress – double shell mechanical joint for corrugated pipes with high sealing performances

Admin-2@tubiNet2022-12-05T12:35:22+01:00CorPress – double shell mechanical joint for corrugated pipes with high sealing performances

BRIEF DESCRIPTION

Double shell mechanical joint with high sealing performances, for corrugated pipes (PE and PP).

The outer wall is made of polypropylene (PP), and the inner one, which is made of TPE, has a specific shape designed to adhere to the entire outer surface of the pipes that need to be connected. This feature increases the hydraulic seal performances (compared to the traditional systems ones) and adds an anti-slip ability, both particularly useful in specific applications and installation techniques. The union between the two shells that compose the joint takes place on the construction site with stainless steel screws and bolts, which need to be fitted and tightened following the specifications submitted by the producer.

PLEASE NOTE: the corrugated shape of the TPE inner wall of CorPress joints, was designed and made following the external shapes of corrugated pipes made by System Group companies mentioned in the current product page. Therefore, we cannot grant any tightness guarantee in case of usage on corrugated pipes manufactured by other producers.

MAIN FEATURES

High tightness reliability

Easy to install

Anti-slip ability

Training on the repair kit

Eligible for vertical wall or under roof installations (ex. Bridges and viaducts)

High shock absorption capacity

CERTIFICATES:

FUTURA SYSTEMS

Corrugated pipe for rubble suction

Admin-2@tubiNet2023-05-29T17:36:27+02:00Corrugated pipe for rubble suction

GENERAL PRODUCT DESCRIPTION

PE double wall corrugated pipes, internal layer is made of low density PE to increase pipe flexibility. Pipes of Black color, DN/OD 250mm provided in lengths.

MAIN FEATURES

Corrugated outer layer in HDPE

Semi-Corrugated internal layer in LDPE

Jointing of the pipes thorugh anti-unthreading CorPress system

High flexibility

Recyclable

Hydro16 PP corrugated pipes for Non-pressure networks

Admin-2@tubiNet2024-06-20T17:28:37+02:00Hydro16 PP corrugated pipes for Non-pressure networks

BRIEF DESCRIPTION

Double wall corrugated pipes made of polypropylene (PP) for non-pressure systems, with a smooth and orange inner surface and a corrugated black outer one. The range of Outer Diameters (DN/OD) goes from 200 up to 1200 mm, while the range of Inner Diameters (DN/ID) goes from 250 up to 1000 mm. Pipes are delivered in bars.

MAIN FEATURES

High ring stiffness: SN 16

Wide range of diameters

Socket or coupling connections with gasket

Lightweight and easy to install

High chemical and abrasion resistance

Inert to stray currents

Recyclable

CERTIFICATES:

MAGNUM HDPE double wall corrugated pipe for non-pressure networks

Admin-2@tubiNet2024-07-02T09:32:59+02:00MAGNUM HDPE double wall corrugated pipe for non-pressure networks

BRIEF DESCRIPTION

Double wall corrugated pipes made of high density polyethylene (HDPE) with a smooth inner surface and a corrugated outer one, available in black colour.

The Outer Diameter (OD) goes from 125 up to 1200 mm, while the Inner Diameter (ID) goes from 250 up to 1000 mm. Pipes are delivered in bars.

MAIN FEATURES

Wide range of diameters

Ring stiffness: SN 4-8

Smooth on the inside and corrugated on the outside

Socket or coupling connections with double sealing gasket

Lightweight and easy installation

High chemical and abrasion resistance

Inert to stray currents

Recyclable

CERTIFICATES:

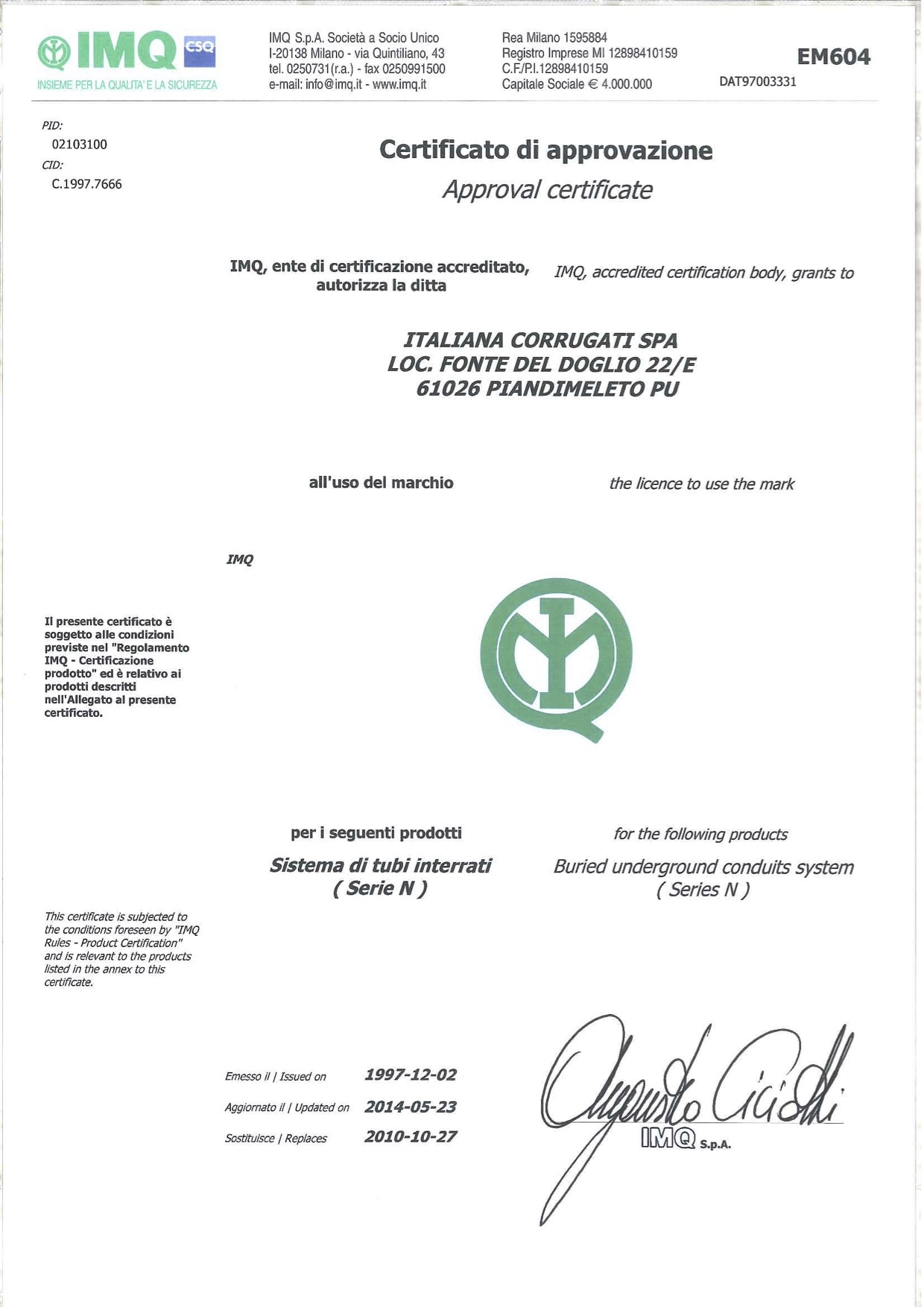

ITALIANA CORRUGATI

IIP Cert.n°2004 Rev.0_ITALCOR MAGNUM

IIP Cert.n°2006 Rev.0_ITALCOR MAGNUM

PIIP Cert.n°2003 Rev.0_tipo B MAGNUM

PIIP Cert.n°2001 Rev.0 tipo B MAGNUM

LUCANIA

Slow Flow – PE corrugated pipes for high slopes networks

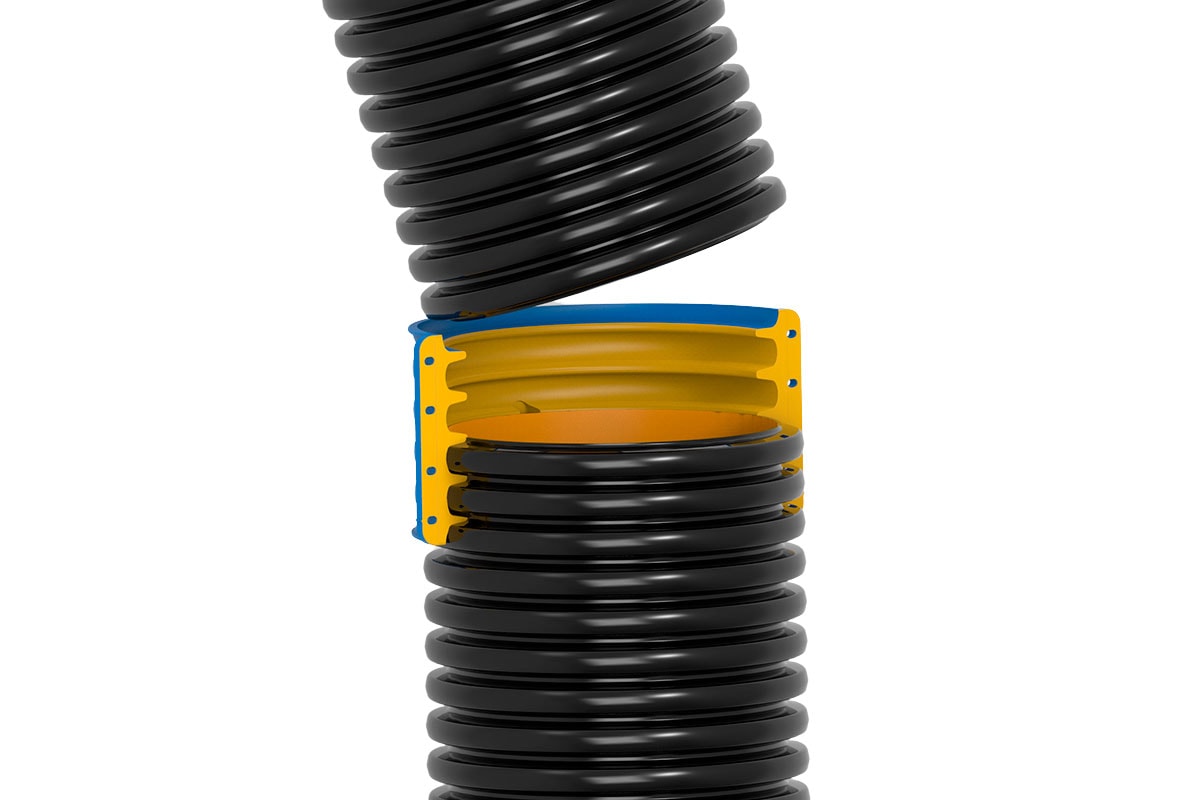

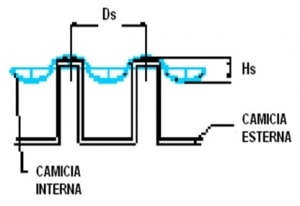

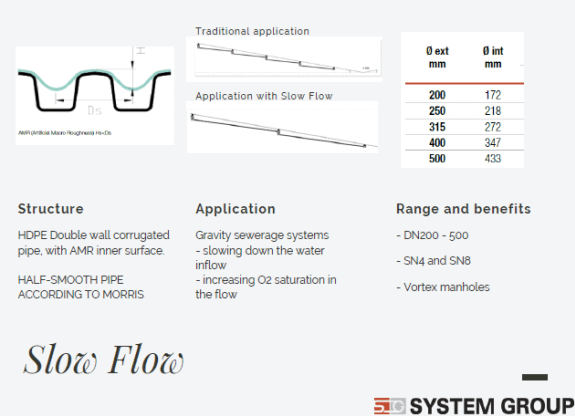

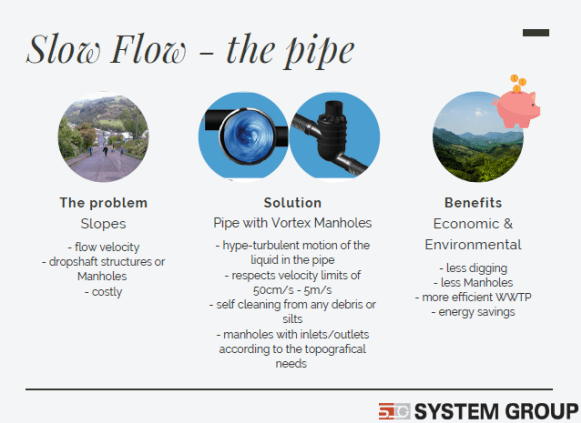

Admin-2@tubiNet2022-04-28T10:07:40+02:00Slow Flow – PE corrugated pipes for high slopes networks

BRIEF DESCRIPTION

Double wall corrugated pipes made of high density polyethylene (HDPE), with a corrugated outer surface and provided with artificial macro roughness (AMR) in the inner surface. Pipes are available in black colour, with a diameters range (DN/OD) that goes from 200 up to 500 mm. They are delivered in bars and are used for the construction of drainage systems laid at a high slope on which it is necessary to slow down the flow speed of fluids. The hydraulic behaviour was tested at a qualified test laboratory of a university engineering faculty in Italy.

MAIN FEATURES

Ring stiffness: SN 8

Corrugated outer wall and wavy inner surface

Ability to slow down the speed of water up to slopes of 20%

Reduction of height and number of drop manholes

Socket or coupling connections with sealing gasket

Pipes can be connected with the CorPress joint

Lightweight and easy to install

High chemical and abrasion resistance

Inert to stray currents

Recyclable

CENTRALDRENI HDPE solid wall slotted pipes for drainage

Admin-2@tubiNet2024-07-01T15:30:13+02:00CENTRALDRENI HDPE solid wall slotted pipes for drainage

BRIEF DESCRIPTION

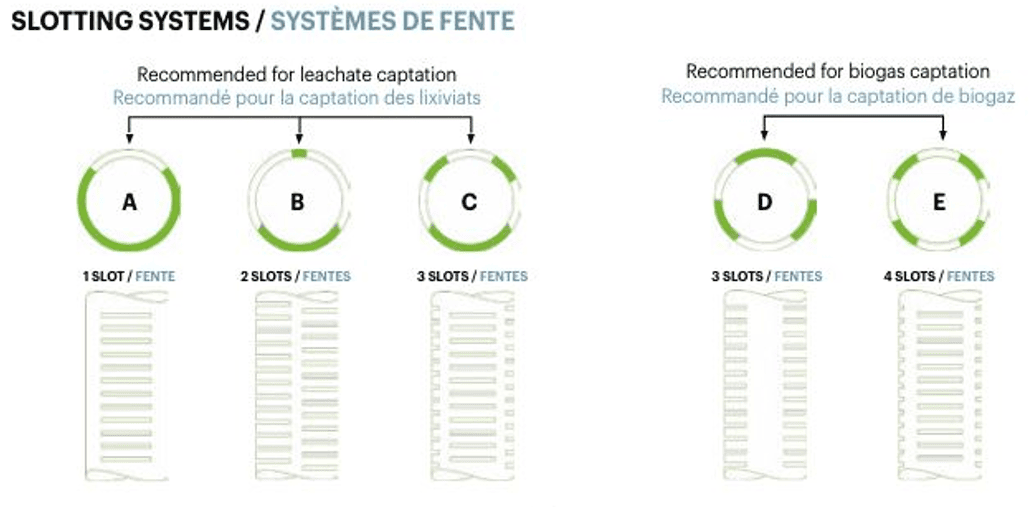

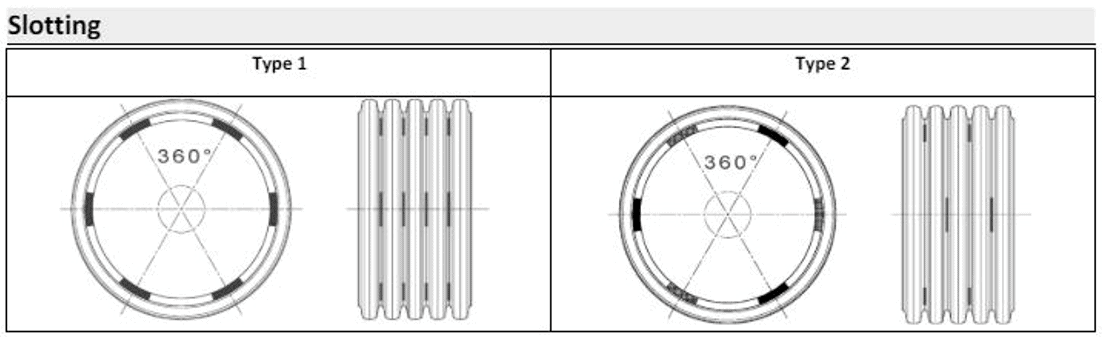

Solid wall pipes made of high density polyethylene (HDPE) with a smooth inner and outer surface, available in black colour. They are provided with transverse slots of different sizes and layout and are used for the construction of underground drainage systems for liquids, landfill leachate and biogas collection. The diameters (OD) range goes from 75 up to 400 mm and pipes are delivered in bars. Upon request, they can be certified PSV (Plastica Seconda Vita – Second Life Plastic) when are made with HDPE obtained from separate waste collection to guarantee that the products can be traced back so being part of circular economy model.

MAIN FEATURES

Wide range of slots layout

Long-range bending

Plastic behaviour in unstable situations

Wide range of fittings and special pieces, standard and customized

Inert to stray currents

High abrasion and chemical resistance (ISO/TR 10358)

High shock absorption capacity

Recyclable

CERTIFICATES:

CENTRALTUBI

FILDREN PE double wall slotted corrugated pipes for underground drainage with geotextile coating

Admin-2@tubiNet2024-07-01T15:17:53+02:00FILDREN PE double wall slotted corrugated pipes for underground drainage with geotextile coating

BRIEF DESCRIPTION

Double wall corrugated pipes made of high density polyethylene (HDPE) or polypropylene (PP), smooth on the inside and corrugated on the outside, provided with slots for the groundwater drainage and with an external PP coating sock filter made of non-woven fabric, connected through the sewing technique. The diameters range goes from DN/OD 125 up to 1200 mm and pipes are delivered in coils and bars. They find application in underground drainage systems.

MAIN FEATURES

Pre-installed coating sock filter

Sock filter basic weight = 150 (± 10) g/m2

Colour of the external sock: green (coils) or white (bars)

Close bending radius (coils range)

Coupling connections

Ring stiffness: SN4 and SN8 for PE pipes, SN16 for PP pipes

Lightweight and quick to install

High chemical and abrasion resistance

Inert to stray currents

Recyclable

BLACKDREN HDPE double wall slotted corrugated pipes for underground drainage

Admin-2@tubiNet2024-07-01T15:21:53+02:00BLACKDREN HDPE double wall corrugated pipes slotted for underground drainage

BRIEF DESCRIPTION

Double wall corrugated pipes made of high density polyethylene (HDPE), smooth on the inside and corrugated on the outside, entirely black (with or without a coextruded coloured stripe) with high UV resistance and provided with slots for the groundwater drainage. The diameters range (DN/OD) goes from 63 up to 200 mm for pipes delivered in coils. They find application in underground drainage systems.

MAIN FEATURES

Shipped in coils

Black colour (with or without a coextruded coloured stripe)

High UV resistance

Close bend radius

Coupling connections

Lightweight and quick to install

High chemical and abrasion resistance

Inert to stray currents

Recyclable

BIG DREN HDPE double wall slotted corrugated pipes for underground drainage

Admin-2@tubiNet2024-07-01T15:29:00+02:00BIGDREN HDPE double slotted corrugated pipes for underground drainage

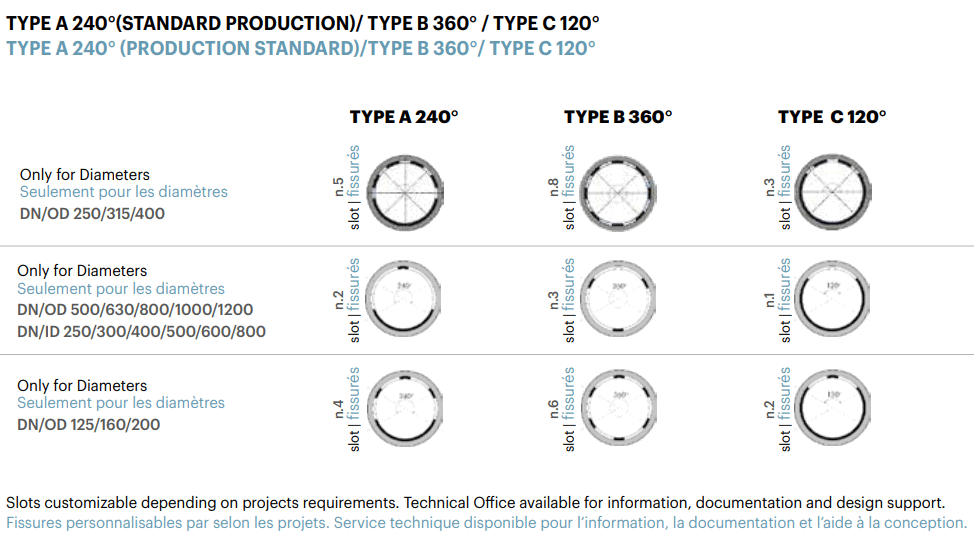

BRIEF DESCRIPTION

Double wall corrugated pipes made of high density polyethylene (HDPE), smooth on the inside and corrugated outside, entirely black with high UV resistance and provided with slots for the groundwater drainage. The diameters range (DN/OD) goes from 125 up to 1200 mm for pipes delivered in lengths. They find application in underground drainage systems.

Range of drainage slots layouts:

MAIN FEATURES

Shipped in bars

Entirely black colour (High UV resistance)

Coupling connections

Lightweight and quick to install

High chemical and abrasion resistance

Inert to stray currents

Recyclable

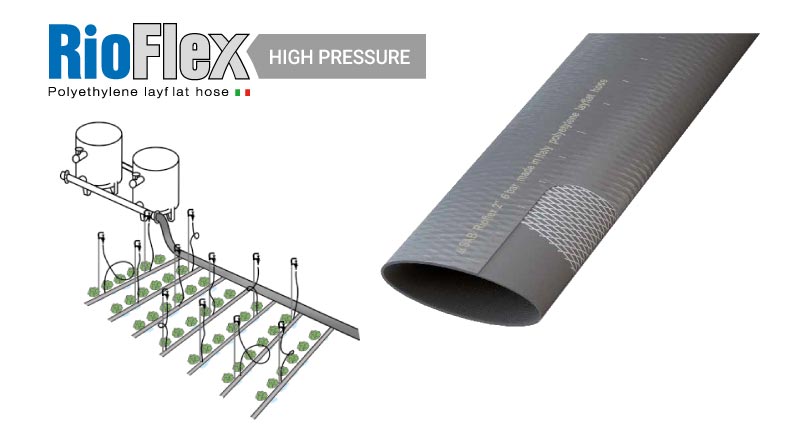

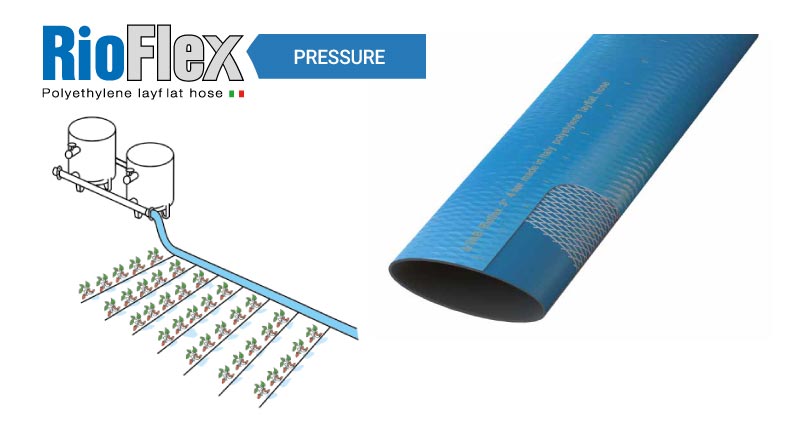

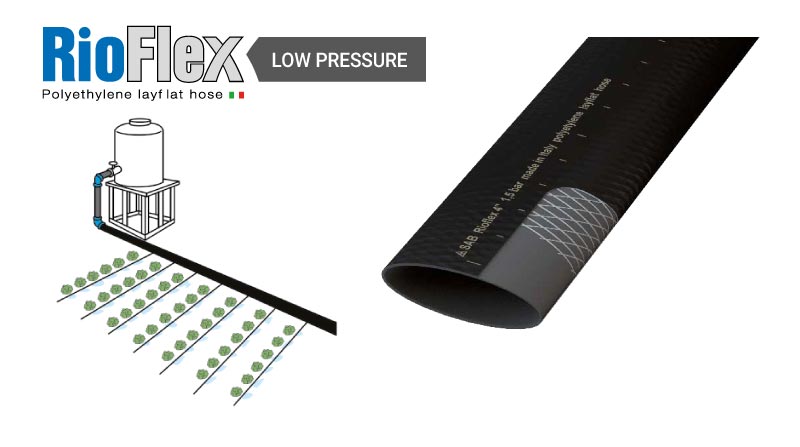

RioFlex – Polyethylene LayFlat Hose

Admin-2@tubiNet2023-04-12T15:47:53+02:00RioFlex – Polyethylene LayFlat Hose

BRIEF DESCRIPTION

Distribution pipe for drip irrigation systems. Rioflex is an handy solution, resistant and entirely recyclable, in order to facilitate the laying and storage operations after the season. These benefits are possible thanks to the polyethylene features that makes up for 100% this layflat, including the reinforcing net. Rioflex is particularly lighter than the classic PVC layflats and can be provided with built-in derivations or they can be installed on the site through the specific kit which consists of pliers, insert and locking wrench.

Rioflex is available in four different versions in order to satisfy the needs of the majority of drip irrigation systems or sprinkling irrigation systems with hoses and driplines or irrigation through sprinkler and mini sprinkler:

- High Pressure (max 6 bar)

- Pressure (max 4 bar)

- Low Pressure (max 2,5 bar)

- Free Flow (max 0,5 bar)

Pipe has a low inner roughness in order to reduce the pressure drop and has a low reaction to thermal shocks. The pack includes the usage and maintenance instructions and, once the product reaches the end of its useful life, Rioflex can be recycled along with the polyethylene hoses.

MAIN FEATURES

Easy and quick to install

Lightweight

Low inner roughness

100% recyclable

TUBONE – smooth HD or MD PE pipes for self-propelled irrigation machines

Admin-2@tubiNet2021-06-07T11:33:55+02:00TUBONE – smooth HD or MD PE pipes for self-propelled irrigation machines

BRIEF DESCRIPTION

Medium or high density polyethylene pipes, with inner and outer smooth surface, available in black colour. The diameters range (OD) goes from 40 up to 160 mm. Pipes are delivered in coils with various lengths depending on the client’s request. They are used for equip self-moving irrigating machines.

MAIN FEATURES

Good bending property

High abrasion resistance

Pipes can bear multiple windings and unwindings

Wide range of diameters and pressure classes (sizing optimization)

High chemical resistance (ISO/TR 10358)

High shock absorption ability

Recyclable

Drip line

Admin-2@tubiNet2021-06-07T11:34:10+02:00DRIPLINE

BRIEF DESCRIPTION

Pipes made of polyethylene PE for drip irrigation, available in brown colour, with an OD of 16 mm and delivered in coils of 100 m. They are particularly recommended for the irrigation of flowerbeds and decorative hedges, as well as for shrub, vineyards, olive groves and fruit trees.

MAIN FEATURES

Easy to install

Reduced friction loss

Double version: standard and self-compensating

Excellent water distribution

MAGO – SKY – SABTAPE – drip tape for irrigation

Admin-2@tubiNet2021-07-22T13:53:49+02:00MAGO – SKY – SABTAPE – drip tape for irrigation

BRIEF DESCRIPTION

Continuous labyrinth drip tape for drip irrigation of horticultural and extensive crops with a maximum thickness of 15 mils (0.381 mm). These performing and efficient solutions allow to save water and increase the crops yield. Thanks to the large section labyrinth, which ensures a water turbulent flow and an high resistance to occlusions, they guarantee an uniform water and fertilizers distribution to the crops, with the best wing lengths available on the market. Our drip tape are manufactured with spacing of 10, 20, 30, and 40 cm, with a range of capacities that goes from 0,6 up to 2,0 l/h and a maximum thickness of 15 mil. There are 3 versions:

- MaGo – high performances drip tape. It consists of an individual coextruded pipe and ensures high performances with the best wing lengths available on the market.

- Sky – high quality drip tape produced through extrusion and subsequent walls gluing. It is more competitive than other drip tapes thanks to its thin thicknesses, especially in its tight spacing.

- Sabtape – high quality drip tape produced through extrusion and subsequent walls gluing with the outer coextruded coloured stripe. It is the highly competitive solution thanks to its thin thicknesses, especially in its tight spacing.

MAIN FEATURES

Excellent uniformity of distribution

High resistance to occlusions

High water saving

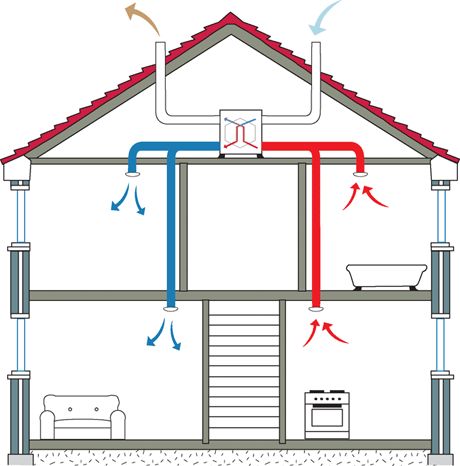

AIRCOR PE double wall corrugated pipes for CMV (Controlled Mechanical Ventilation)

Admin-2@tubiNet2024-06-25T09:56:12+02:00AIRCOR PE double wall corrugated pipes for CMV (Controlled Mechanical Ventilation)

BRIEF DESCRIPTION

Double wall corrugated pipes with high flexibility, with the outer corrugated surface made of high density polyethylene (HDPE) and the inner smooth one made of low density polyethylene (LDPE). The diameters range goes from DN/OD 63 up to 200 mm and the pipes are delivered in coils placed on pallets. Aircor finds application in controlled mechanical ventilation systems inside buildings. The standard colour is white, but the DOUBLE BAND version (on request) is provided with two coextruded coloured stripes on the outer surface (one stripe is blue and the other one is red) placed on the two opposi

te sides. The allocation of the coloured stripes allow to distinguish between the pipes designed for the air supply and the one designed for the air extraction. CMV systems are placed inside the constructions, both civil and industrial, for accomplish this aims:

- Control the inner air healthiness between the various rooms in order to reduce the development of re

spiratory disease, viral shedding etc; - Adjust the humidity level in order to prevent the mould growth;

- Optimize the inner air exchange management with the outside in order to increase the energy systems efficiency of buildings.

Aircor pipes are manufactured with certified antistatic and antibacterial materials. The ISOAIR version adds an outer coating for the thermal and sound isolation to the standard Aircor pipe (grey/black colour).

MAIN FEATURES

Antistatic material

Antibacterial material

Ease and speed of installation

Close bending radius

ISOAIR version with thermal and sound isolation

Sleeve connection

Recyclable

BLACKCOR – HDPE double wall corrugated pipes for cable protection

Admin-2@tubiNet2024-07-24T15:25:06+02:00BLACKCOR – HDPE double wall corrugated pipe for cable protection

BRIEF DESCRIPTION

Double wall corrugated pipes made of high-density polyethylene (HDPE), smooth on the inside wall and corrugated outside, for underground cable protection networks.

Diameters (DN/OD) go from 40 up to 200 mm, all available in coils, and in lengths from DN75 mm size.

Standard colour is totally black, to increase the UV resistance. It can be equipped with one coextruded coloured stripe on the outside wall, according to customers’ need.

MAIN FEATURES

Wide range of diameters

Ring stiffness: 450 – 750 N

Impact test classification: N

Close bending radius

Coupling connections

Accessories: Coupling sleeve + polypropylene/polyester wire puller.

High UV resistance

Lightweight and easy to install

Standard bands color: white/light grey, customized color available on demand.

High chemical resistance

Inert to stray currents

Recyclable

TECHNICAL CHARACTERISTICS

UV resistance according to EN1297 test, up to 5000h (one year warranty)

Crush resistance: 450N – Standard EN 61386-1/2008 and EN 61386-24/2010 series N (IIP and IMQ certified)

Bending radius: 15 times the outer diameter.

Operating limits: -50 °C / +60 °C.

Electrical rigidity*: Excellent (polyethylene 20-30 kV/mm)

*Electrical rigidity, also known as dielectric strength or breakdown voltage, represents the ability of a material to withstand a certain electric voltage before a discharge or breakdown occurs. High electrical rigidity is desirable in materials intended for electrical insulation, such as those used in cables, transformers, capacitors, and other electrical and electronic components.

Electrical rigidity is primarily classified based on the breakdown voltage, which depends on the material and its thickness.

PE double wall corrugated pipes for telecom cable protection

Admin-2@tubiNet2023-03-28T10:07:27+02:00PE double wall corrugated pipes for telecom cable protection

BRIEF DESCRIPTION

Double wall corrugated pipes made of high density polyethylene (HDPE), smooth on the inside and corrugated on the outside. The diameters range (DN/OD) goes from 40 up to 200 mm and pipes are delivered in coils and bars. They find application in networks. Colours and performances are created in accordance with the client technical information. (the blue-blue colour is the “Telecom Italia” standard for fibre optic cables).

MAIN FEATURES

Wide range of diameters

Rings stiffness: 450-750 N

Impact resistance class: N

Small bending radius

Sleeve connections

Lightweight and quick to install

High chemical and abrasion resistance

Recyclable

CERTIFICATES:

ITALIANA CORRUGATI

Single Wall corrugated Pvc Pipe

Admin-2@tubiNet2021-07-09T11:03:47+02:00Single Wall corrugated Pvc Pipe

STRUCTURE: black single-wall corrugated pipe with IMQ mark

USE: electric cable protection

PACKAGING: coils of 25 meters Ø 32 mm and of 50 meters Ø 25 mm

SGPVC Sewer – PVC solid wall pipes for sewerage networks

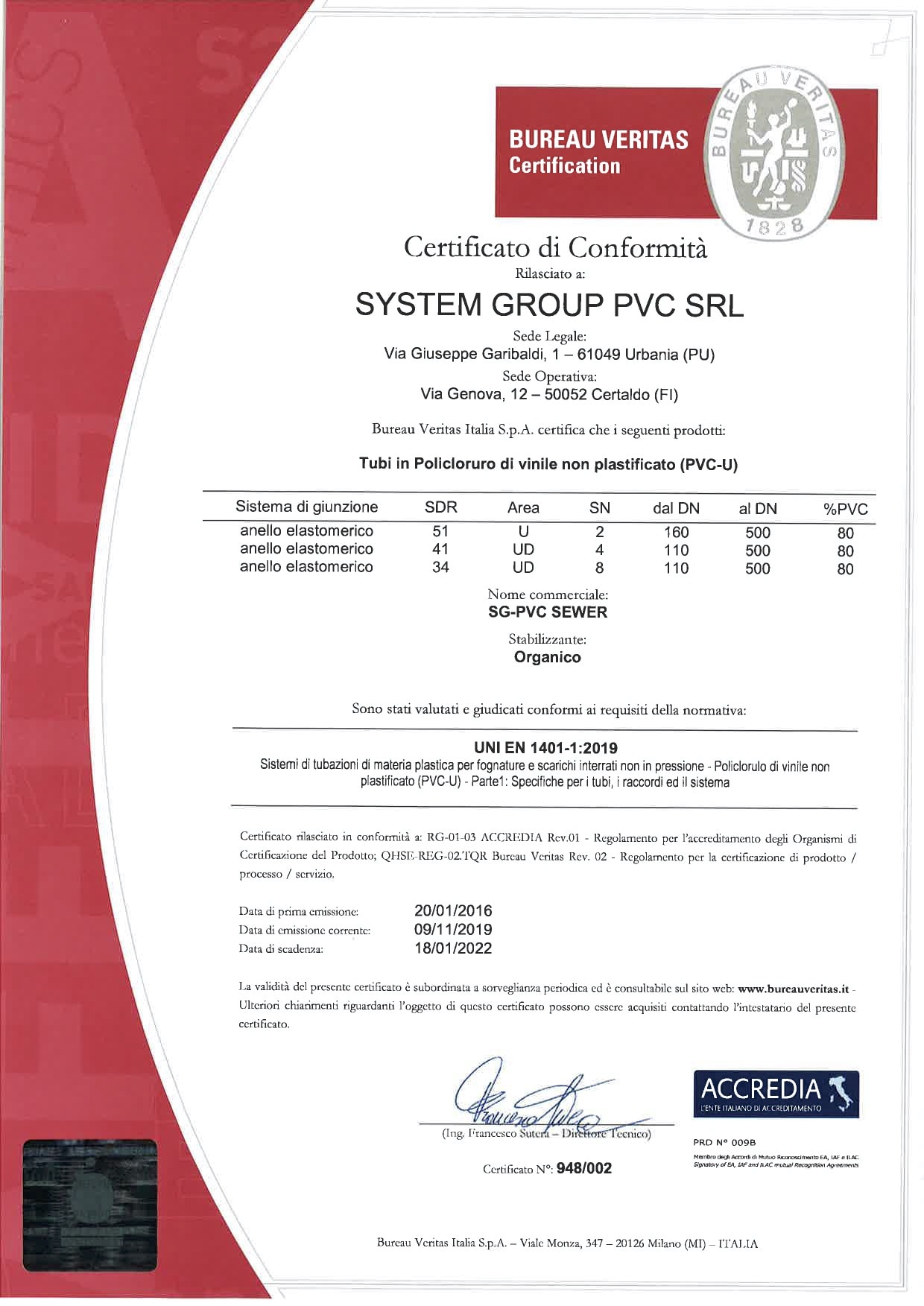

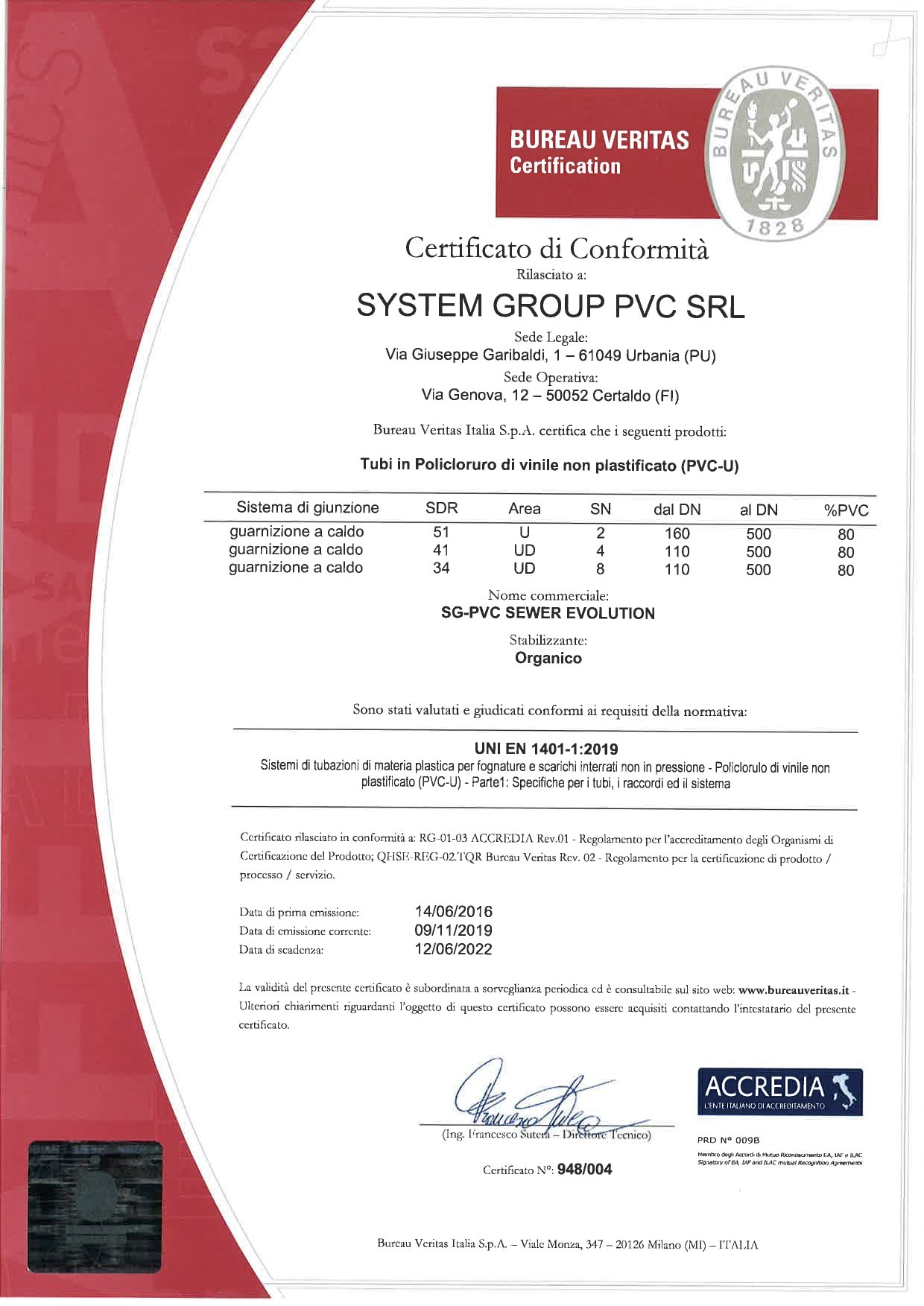

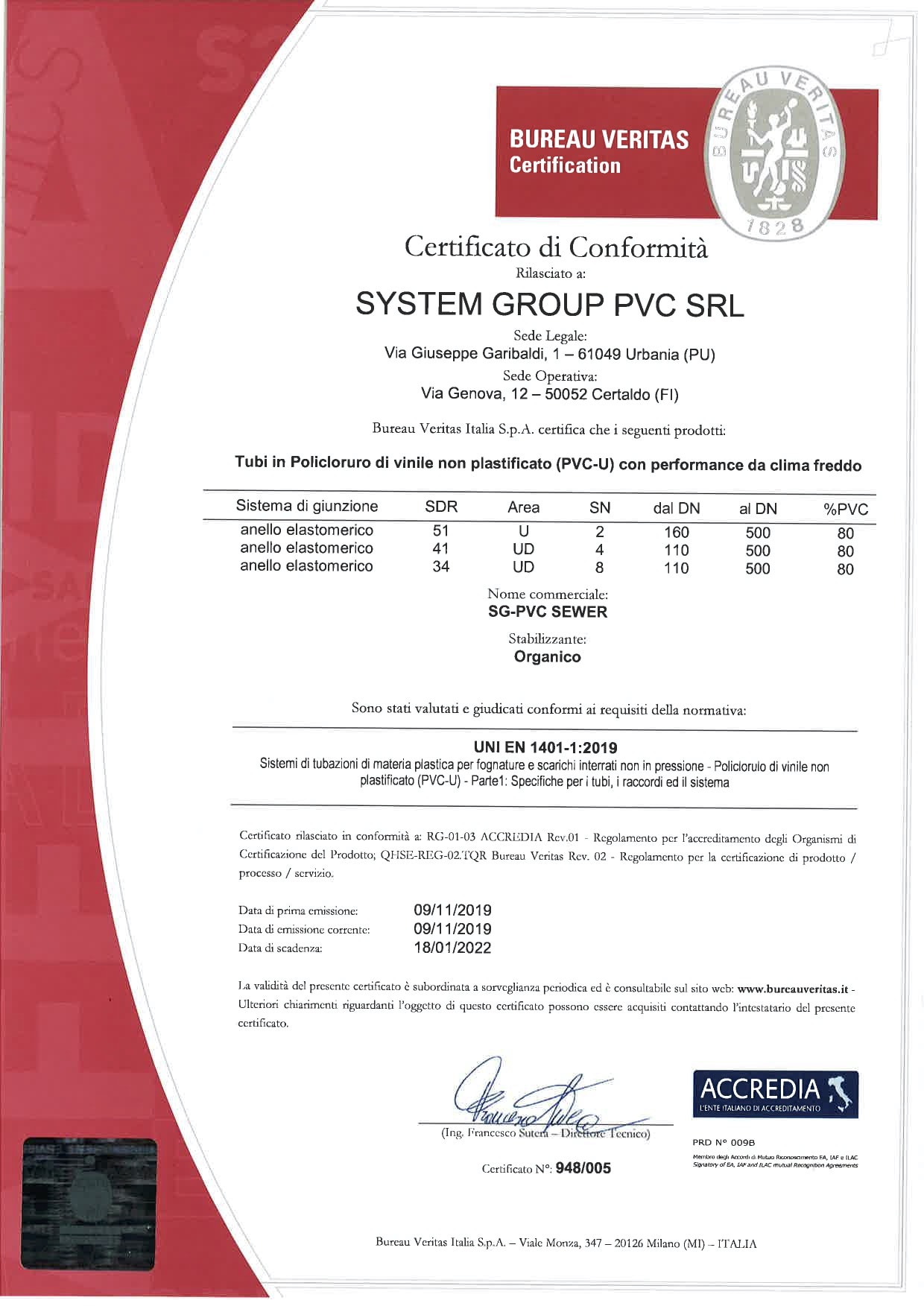

Admin-2@tubiNet2024-07-25T15:33:12+02:00SG-PVC Sewer – PVC solid wall pipes for sewerage networks

BRIEF DESCRIPTION

Solid wall pipes made of polyvinyl chloride (U/D-PVC), available in brick-red colour (RAL 8023). The diameters range (OD) goes from 110 up to 500 mm. Standard pipes are delivered in 3 or 6m lengths with a built-in socket provided with a gasket. Glue connection available on demand. They are used for the construction of non-pressurized waste systems, outside the buildings (code: “U”), buried inside the building (code: “D”).

For Circular Economy goals, pipes can be partially made (on demand) with recycled material, guaranteed by PSV mark (Plastica Seconda Vita – Second Life Plastic).

MAIN FEATURES

Ring stiffness: SN 2 – 4 – 8